“Then, in 2021 we landed two very large nonautomotive industrial customers, stretching our capacity thin,” Gido adds. Those new customers brought the firm’s active-customer base to around 15. “We had to add capacity to handle that growth,” says Gido.

Add capacity it did, building a 25,000-sq.-ft. addition onto the plant in 2021 to bring total square footage to 92,000, and provide the floor space needed to welcome its three new presses. Soon it will add another 25,000 sq. ft. to make room for the 1100-ton press.

Automated Feed Lines

The TrimLine press lineup starts at 200 tons and peaks at 660 tons (prior to the coming addition). Its first two servo presses were 660-ton models, added in 2021 and 2022; 2023 welcomed a 440-ton servo. All are Aida models, outfitted with Dallas feedlines rated for coils to 30,000 lb. of material (48 in. wide on the 660-ton lines, 36 in. on the 440-ton line)—either cold- or hot-rolled mild steel, or aluminum sheet (Types 3003, 5052 or 5754), typically 0.060 in. thick.

The TrimLine press lineup starts at 200 tons and peaks at 660 tons (prior to the coming addition). Its first two servo presses were 660-ton models, added in 2021 and 2022; 2023 welcomed a 440-ton servo. All are Aida models, outfitted with Dallas feedlines rated for coils to 30,000 lb. of material (48 in. wide on the 660-ton lines, 36 in. on the 440-ton line)—either cold- or hot-rolled mild steel, or aluminum sheet (Types 3003, 5052 or 5754), typically 0.060 in. thick.

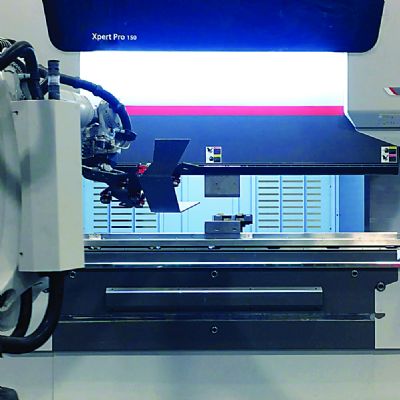

Notable with its latest press line is the addition of feed-line automation, under the Dallas moniker AutoSet. The automation, which fosters job-setup speed and repeatability, includes job-setup parameters for feeder passline height and edge guides, straightener break rolls and edge guides, coil guide rolls to enable automatic coil centering, and an automatically adjusting drag brake based on coil OD.

Also included: Allen-Bradley controls along with Dallas’ Sync-Loop and ProfileSelect options. SyncLoop technology, say Dallas officials, monitors average line speed and loop depth, and automatically adjusts payout speed to ensure a smooth payout. Loop-height setpoints store within each job recipe, providing highly tuned feed and loop control for each job.

The ProfileSelect feed control employs a sinusoidal (cam-motion) profile that results in a smooth feed motion utilizing 100% of the press-feed window. While servo-feed controls that employ a trapezoidal motion profile can create quick, jerky motions that may cause slippage, material damage and added stress to machine components, the sinusoidal profile results in smooth feeding that reduces stress on the material and the feed’s mechanical components.

Transmission Specialists

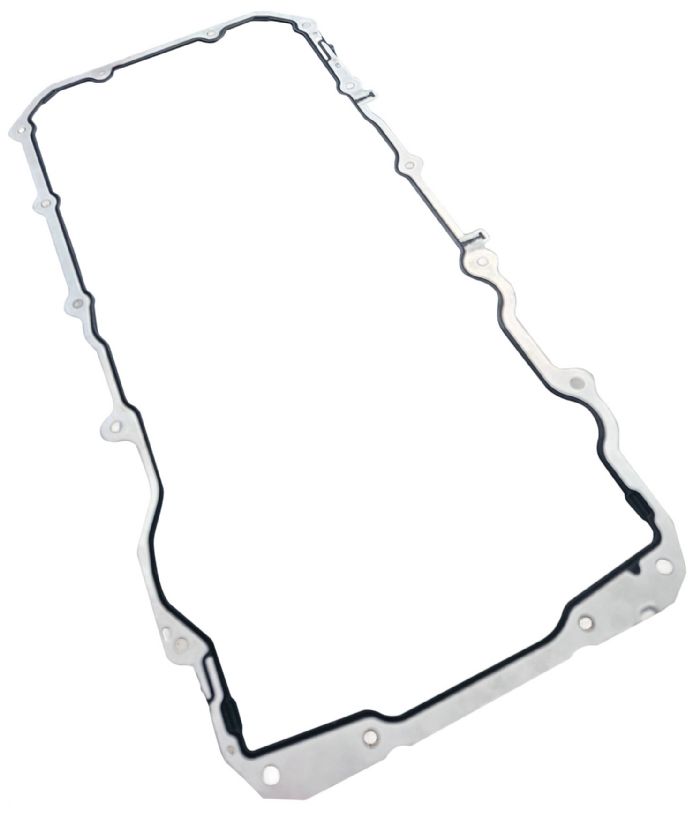

Much of the automotive work performed at TrimLine comprises transmission parts; a big runner is steel and aluminum gasket frames stamped as right- and left-hand parts in progressive dies. Those parts ship to customers who then load them into molds to receive gaskets—think transmission-pan or oil-pan gaskets, for example.

“When we brought the servo presses in and started to move some of the tools over from our conventional mechanical presses, we saw an immediate increase in productivity of 25 to 30%,” shares TrimLine general manager Todd Hardoby. That’s a direct result of the stroke profiling provided by servo technology—running in pendulum mode, and the ability to minimize stroke length.

“That’s obviously a significant productivity gain,” Hardoby adds, “but even more important because our volumes are so high. We can turn projects around much quicker than in the past, keeping our customers satisfied. We haven’t missed a delivery date since the new presses arrived.”

Hardoby also appreciates the ability to slow the press speed down as the ram approaches bottom dead center. “That reduces reverse tonnage,” he explains, “prolonging tool life and protecting the press.”

On the shop floor, Hardoby and his press operators appreciate the ease of which the Dallas feeds are set up and programmed for each job.

…and a fourth on the way (1) Aida DSF-M2-4000 (1—on the way) Aida DSF-M2-10000 |

“We manage the feed settings through each part program,” he says, noting that the feed-line control and press control conveniently located next to each other, making it easy for the press operator should he need to fine-tune the feed program before starting a production run. “And, our press operators are highly trained, a few having attended Aida’s annual servo-technology symposium, and receiving advanced training. They’re able to program the presses and feeds themselves when we bring in new programs. That’s a huge benefit, versus having to call over a supervisor or engineer to program the jobs.

“I’m always impressed with the skill level of our operators,” Hardoby adds. “They manage to squeeze every bit of efficiency from those new lines. And, our staffing level is growing as we speak, as we soon expect to kick off two new automotive programs later this year for transmission parts. We’re already at 40 employees, an increase from 35 earlier this year, and by year-end, when that new 1100-ton press fires up, we expect to be at 65 to 70 employees.”

What fuels this high level of growth? “I’m going to say we’re competitive with pricing,” explains Gido. “We’re not the lowest cost, but we’re competitive. And as we said, since adding these new press lines we’ve not missed a single delivery date, and our quality has been near-perfect. We’re, in fact, called out as a ‘preferred supplier’ with all of our highest-volume customers. That’s where we want to be.”

OEE Top of Mind

As a contract stamper serving such high-volume customers, press-line run time (measured by overall equipment effectiveness, or OEE) represents a critical success factor. For Hardoby, who previously worked for stampers specializing in shorter-run work where key performance indicators (KPIs) included activities such as quick die changes, the critical KPI is run time.

“The ongoing emphasis here is keeping the presses running,” he says. “When you’re faced with turning out 500,000 parts in a matter of days, the presses have to be going down and up. We must be prepared to respond to any issues. We keep spare die details on the shelf, along with critical press components, and maintain a full tool shop if we ever need to make quick work of any tooling.”

Also proving helpful, Hardoby says: “In order to provide worldclass service, Aida supplied an industrial VPN router as a part of the machine control system. This integrated device, manufactured by eWon, allows Aida to access the press safely and assist with troubleshooting and remote diagnostics.

“That’s just one more key factor to ensuring we have little to no unscheduled downtime,” Hardoby adds. MF

View Glossary of Metalforming Terms

See also: Dallas Industries, Aida-America Corp.

Technologies: Coil and Sheet Handling, Stamping Presses

“We love bidding on programs of 2 to 5 million parts,” says David Gido, president of TrimLine, a division of Cleveland, OH-based Varbros, LLC. “That’s what we look for; that’s what we like.”

“We love bidding on programs of 2 to 5 million parts,” says David Gido, president of TrimLine, a division of Cleveland, OH-based Varbros, LLC. “That’s what we look for; that’s what we like.”