Where Servo-Electric Presses Fit

January 11, 2022Comments

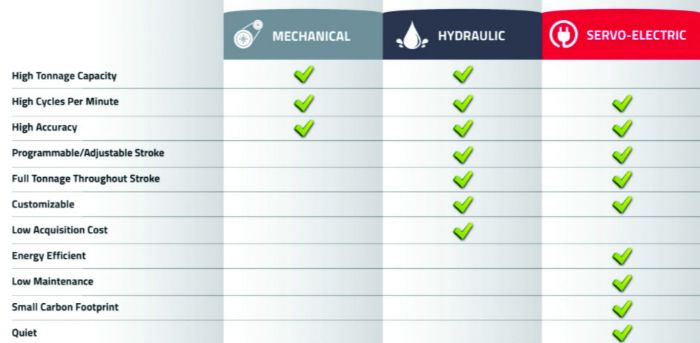

How does a servo-electric press work, and when does it make sense—or not—over hydraulic and mechanical presses?

Much has been written on the anatomy and characteristics of servo-driven presses—most commonly for servomechanical presses, a little less for servohydraulic models and not much at all for servo-electric presses. To add to the servo-electric knowledge base, MetalForming quizzed Josh Dixon, a Beckwood Press Co. veteran and recently named chief operating officer for the St. Louis, MO-based provider of hydraulic and electric press systems, including servo models and custom configurations.

MetalForming: How is a servo-electric press put together, and how does it work?

MetalForming: How is a servo-electric press put together, and how does it work?

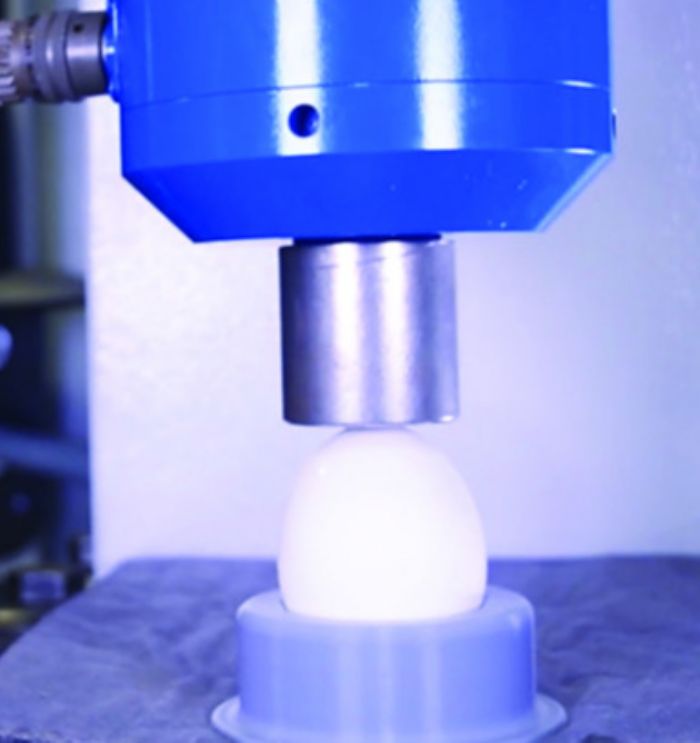

Josh Dixon: From an anatomy standpoint, a servo-electric press features a similar structure to that of a hydraulic press. In place of a hydraulic cylinder for generating force, a servo-electric press employs a roller-screw electromechanical actuator—a mechanical actuator driven by a servo motor. The servo motor replaces the motors, valves, pumps and related components typically found in hydraulic presses with an electric and mechanical drive train.

MF: How does this replacement affect performance?

JD: A servo-electric press features much tighter position and force control than can be achieved with a hydraulic press, offering programmable positional accuracy of ±0.0005 in. And, while mechanical presses excel at achieving the same position at the bottom of the stroke cycle-after-cycle, they don’t allow for a level of programmability where users can easily change it from tool-to-tool or part-to-part. Servo-electric presses maintain many of the same benefits of hydraulic presses, such as full tonnage throughout the stroke, extended dwell and programmable cycle profiles.

A servo-electric press also eliminates the need for hydraulic fluid. From a maintenance perspective, or a desire to move away from fossil fuels, or perhaps an application where hydraulic oil can contaminate a product (food-grade applications, for example), elimination of hydraulic fluid nets a positive.

MF: Conversely, when are servo-electric presses not the ideal options?

MF: Conversely, when are servo-electric presses not the ideal options? We receive everyday exposure to a variety of industries and applications—metal and nonmetal, from OEMs to Tier suppliers to job shops, which enables the opportunity for cross-pollination—introducing applications from certain industries to unrelated applications and industries.

We receive everyday exposure to a variety of industries and applications—metal and nonmetal, from OEMs to Tier suppliers to job shops, which enables the opportunity for cross-pollination—introducing applications from certain industries to unrelated applications and industries.

Webinar

Webinar