Tonnage and Energy

September 1, 2008Comments

It is essential to understand that press tonnage and press energy are not one in the same. The tonnage rating of any press is the largest load, in tons, that the press can withstand without causing structural damage to the machine frame, slide-adjusting mechanisms, pitman (connection rods) or main gear bushings. The energy rating of a press is a function of applied press loads and the distance through which the loads are applied.

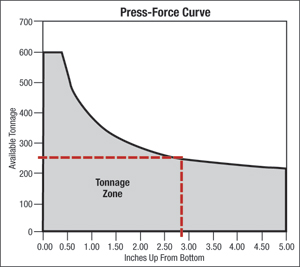

Unlike hydraulic presses, mechanical presses have their full rated force available only near the very bottom of the press stroke. Cutting, bending, embossing and other operations that generally occur near the bottom of the stroke can take advantage of the full rated tonnage capacity of a mechanical press.

Deep-drawing operations, on the other hand, tend to start several inches above the bottom of the press stroke. Since the working capacity of a mechanical press is a function of its structural design, gearing, motor size, flywheel mass and other variables, the machine’s maximum working capacity (tonnage) is a fixed value. When working distances increase, as with deep-drawing operations, the

|

| Fig. 1 |

For instance, deep drawing 3 in. off bottom in a 600-ton mechanical press provides less than 50 percent of the rated machine capacity to carry out the drawing operation. De-rated tonnage is a term used to describe this reduction in available force.

The press crankshaft in a mechanical press rotates, which causes the mechanical advantage of the pitman to change constantly. This means that the relationship between force and distance will not be linear. As a result, mechanical-press manufacturers supply force curves that depict available force versus the distance of the slide from the bottom of the stroke. A simplified press-force curve is shown in Fig. 1.