Quick Die Change System...Enables Tier One to Stay Ahead of Parts Demand

January 24, 2019Comments

For Stanley Engineered Fastening's Indiana plant, small parts for automotive is big business, requiring fast, efficient production, making quick die change an important part of its success.

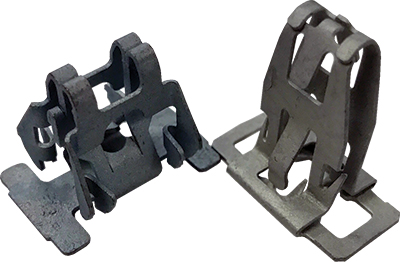

Little parts are a big business for Stanley Engineered Fastening, a Stanley Black & Decker company, with global operations in Asia, Europe, South America and North America serving a range of industries. High-volume clips for a long list of major automotive companies, made at its 133,000-sq.-ft. Montepelier, IN, facility, represent an important part of Stanley Engineered Fastening’s product portfolio.

|

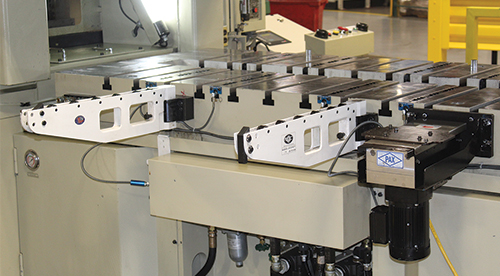

| A swing-down bolster extension enables easy retrieval by die-transport vehicles. |

At the Montpelier facility, achieving fast production ranks high among Stanley’s objectives. Challenges are many as multiple mini clips with multiple bends, used for air bags, grab rails, body panels and other applications, require complex progressive dies, according to Mark Gray, a 14-yr. stamping veteran and 3-yr. plant manager at Stanley Engineered Fastening.

Gray credits a Seyi SM2 straightside press equipped with a complete quick-die-change (QDC) system by Pacesetter Systems, Valencia, CA, for enabling his plant to produce a range of mini parts with orders stretching from 5000 to hundreds of thousands.

Achieving Faster Setup and Production

“Our stamped metal fasteners require long dies with many stations,” says Gray, explaining that the Seyi press and its 84-in. bed makes possible the progressive dies required for the complex bends, while the QDC system facilitates faster changeover between part runs. The QDC system, with its hydraulic in-bolster die lifters, bolster extension and hydraulic die clamps, has enabled Stanley to reduce setup times from 52 min. to just 31.

|

| A swing-down bolster extension enables easy retrieval by die-transport vehicles. |

Achieving faster die changes also meant standardizing plates, bolts, clamps, etc. “There can be 20 different ways to clamp a die,” says Gray, “so we must keep everything standard so that we don’t lose time looking for bolts and clamps. All of our QDC efforts are important because we’re producing many different parts of varying quantities—from as few as 5000 to as many as 300,000.

“Obviously, the quicker we can get the die running,” Gray continues, “the better, as we’re always watching the OEE (overall equipment effectiveness) and looking to reduce lead times.”

Podcast

Podcast