Proper Maintenance and Care for your Hydraulic Presses

October 1, 2008Comments

Adhering to a routine preventive-maintenance schedule is the most important aspect of consistent, trouble-free hydraulic-press operation. Adequate planning coupled with a commonsense, proactive approach will optimize press life and productivity.

Following a strict preventive-maintenance (PM) schedule outlined by the hydraulic-press manufacturer will ensure optimum press productivity and reduce the risk of costly downtime. Those that dedicate time toward the maintenance and health of their hydraulic presses will surely realize how sound an investment a good PM plan is.

|

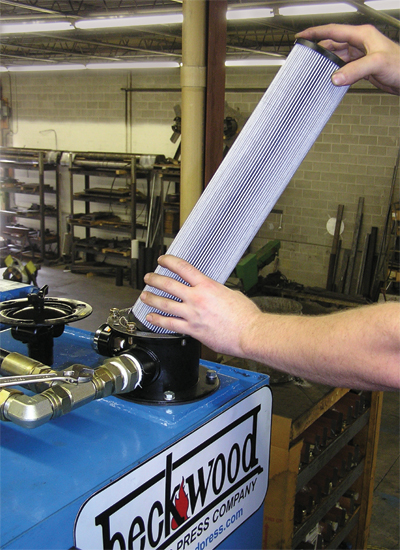

| Check and change your oil filter regularly to reduce the risk of oil contamination. |

While similarities exist betweenall hydraulic presses, each press should be considered individually when developing a PM schedule. Depending on the environment in which the press operates, the application for which the press is being used, and the frequency with which the press is used, maintenance schedules may vary dramatically.

Accounting for Heat, Shock and other Factors

For example, a press operating in an open-air facility in a heated environment will require a more intensive maintenance schedule compared to a press running in a climate-controlled facility with constant temperature and humidity. Therefore, operators should be aware of their surroundings and increase the level of press maintenance when working in more demanding environments.

In addition to the operating environment, certain applications, such as simple forming, may not cause as much strain on the press as would compression molding. In addition to the added effects of introduced heat during molding, prolonged dwell cycles also may be applied, which lengthens the amount of time the hydraulic system’s output is being maximized. Another press application that can cause added strain is blanking of higher-strength steels, which causes tremendous breakthrough shock. For such applications, specify a press designed to account for these shock forces. Then, operators of presses used to form high-strength steels should modify maintenance schedules to include more frequent inspections of the press’ structure and hydraulic systems.

Also, a press working in a production system running at 15,000 strokes/day will require a higher level of attention than a hydraulic press cycled 150 strokes/day.

Finally, regardless of the environment, application and duty cycle for a specific hydraulic press, owners/oper-ators of this equipment should review the recommended maintenance schedule with the press manufacturer in order to fine-tune any proposed plan.

Act Proactively

|

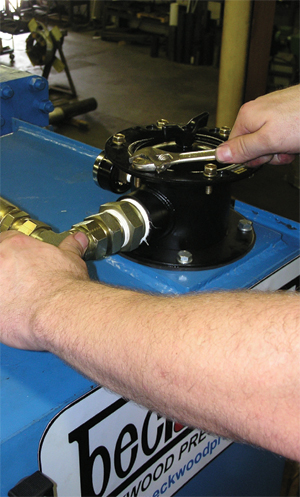

| Tighten nuts and bolts to the proper torque specifications for optimum press performance. |

When maintaining a hydraulic-press system, being proactive may be the first and best rule to follow. Avoiding problems before they arise will save time and money, and will increase the chances that production levels will not suffer due to a press failure. Follow these tips and the health of your press will increase exponentially.

• Follow the prescribed maintenance schedule. The hydraulic-press manufacturer will provide an extensive set of documents, including a preventive-maintenance checklist and schedule; documentation on individual system components; contact information in the event an issue arises; and a detailed operating manual. Although, as previously explained, adjustments should be made to each schedule based on environment, application and usage, the guidelines set by the press manufacturer should act as a firm starting point for maintaining press health.

• Check regularly for leaks. Seemingly insignificant leaks can lead to significant problems. Any leak detected during a regular press inspection should be accounted for by identifying the problem. This may require tightening of fittings or replacing a hose. Once the problem has been addressed, monitor the area to ensure no lingering issues.

• Monitor the nuts and bolts. Press structures rely on a number of nuts and bolts for efficient operation. Among the connection points to be monitored: the cylinder attachment. Upon leaving the press-manufacturer’s facility, cylinder-attachment bolts should be tightened to the proper torque specification and baselines should be applied that aid in the monitoring of these fasteners. Many presses carry marks on all attachment bolts when they have been certified to the proper torque. In addition to cylinder-attachment bolts, bolster-plate and tie-rod pre-tensioning nuts should be monitored regularly.

Monitor Beckwood• Use clean oil. Oil contamination causes many a hydraulic-component failure, and can lead to complete system crashes. Most hydraulic systems can be run with simple return-line filtration circuits using 10-micron filters. However, higher-performance systems using proportional or servo valves require a more stringent filtration system and the use of inline pressure and return-line filters. Regardless of the level of performance, shops should sample the oil in each press periodically and analyze it to verify cleanliness. Also, the press manufacturer will specify the type of filtration required for each system and can act as a reference for any questions regarding oil cleanliness.

|

| Monitor and ensure the reliability of safety apparatus, such as the light curtain shown here, to make sure the press operates as designed and that operators remain protected. |

• Monitor oil level and operating temperature. Improper oil levels can lead to pump inefficiency due to cavitation, where air enters the fluid being pumped. Also, oil running at exceedingly high temperatures can break down prematurely and serve as an early warning sign that certain circuit components are performing inadequately. Monitoring the oil level and operating temperature represents a crucial aspect of hydraulic-press maintenance.

• Record accurate production data. Data-logging, though not used often, is one of the best tools for monitoring press-system performance, and for early detection of issues that may require immediate maintenance activity. For best results, record as much data as possible when the press is commissioned and refer back to those baseline standards periodically. The press manufacturer also should capture baseline data during the press-testing process and report the findings to the customer. Recording items such as operating pressures during rapid advance, pressing and rapid-retract portions of the press cycle can provide valuable data as to the press system’s efficiency. Increases in operating pressures can be a sign that components have begun to fail and that a more in-depth system inspection is needed.

• Monitor safety systems. Safety systems serve a valuable purpose in the operation of hydraulic presses. These important systems should be tested on a daily basis for reliability. Light curtains, gate interlocks, safety mats and the E-stop safety circuit should als be tested prior to press operation. Should any defects be discovered, immediately lockout the press system to allow for proper servicing.

• Be proactive. Most hydraulic presses are constructed of several hydraulic components, either from a single manufacturer or from multiple suppliers. Each supplier specifies an expected service life for each individual component. Replacing components proactively before a failure occurs will save time and money. When one hydraulic component fails, the risk for entire system contamination greatly increases. It is much easier to change out individual components on a regular basis than to wait for a component to fail and possibly affect the entire press system.

A strong relationship that provides open communication between the press manufacturer and the user is crucial to addressing any serious maintenance issues. Whether purchasing a new or used hydraulic press, the stamper should verify that a documentation package is provided and will accompany the press. An acceptable documentation package should include, but not be limited to: hydraulic and electrical schematics, installation/startup instructions, operating instructions, preventive-maintenance schedules and checklists, PLC and touchscreen programs, component literature, oil-sampling information, and customer-support contact information. MF

View Glossary of Metalforming Terms

See also: Beckwood Press Company

Technologies: Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationThe Automation Revolution in Hot Stamping

Katrina Geenevasen September 23, 2024