CD Welders for Advanced Materials

August 23, 2019Comments

Selecting the right capacitor discharge welder requires knowledge of the various types and their capabilities.

|

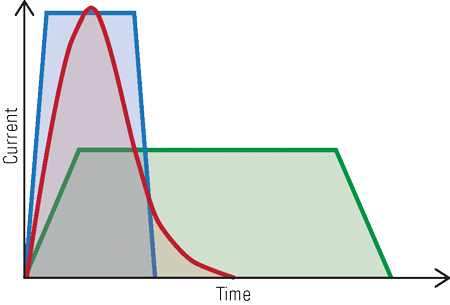

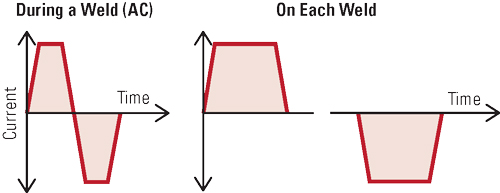

| Fig. 1—Waveforms of three welder types. As with Figs. 2 and 3, the green waveform depicts a mid-frequency direct-current, (MFDC) constant-current waveform with stable weld current. The red waveform depicts a standard CD welder yielding excellent welds by suppressing the heat effect to the workpiece. The blue waveform depicts a variable-waveform CD welder combining the qualities of the MFDC and standard CD welders. |

|

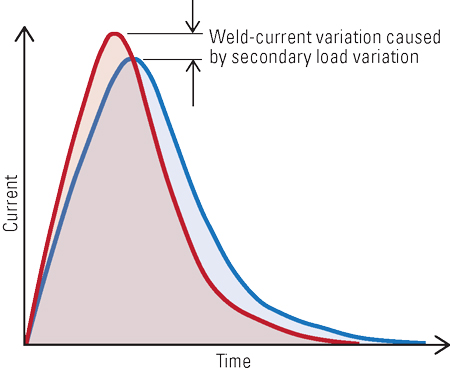

| Fig. 2—Load variations are not compensated for during the welding process, as shown. The result: variation in welding current at the peak of the weld. |

|

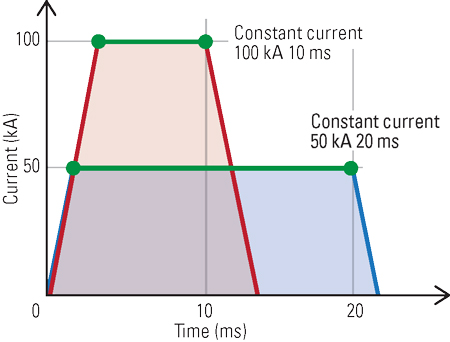

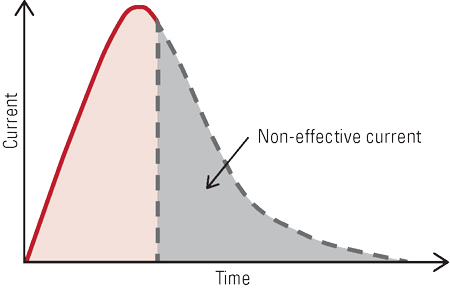

| Fig. 3—Weld current around the peak of the current waveform determines weld strength. Tailing current has no effect on the weld. |

|

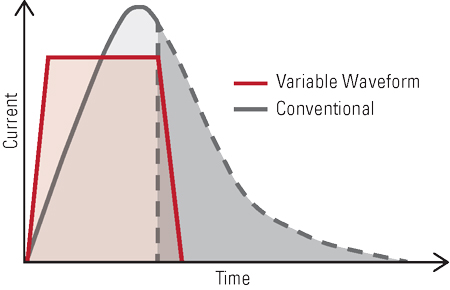

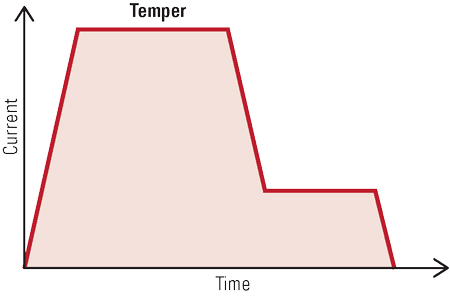

| Fig. 4—Illustrated here: the constant-current capability of the variable-waveform design. |

|

| Fig. 5 |

|

| Fig. 6 |

|

| Figs. 5-7—Precise repeatability of waveforms helps ensure high weld quality. |

Capacitor discharge (CD) welders have been around for many years, but only recently have they moved into the limelight, addressing new resistance welding (RW) challenges. Driving these challenges: automotive’s move toward lighter, more fuel-efficient vehicles with parts and assemblies made of high-strength and ultra high-strength steel, with the newest of these materials being hot stamped steel.

The challenge with welding hot-stamped steel: To join the materials the welder must deliver very high currents and forces for a very short time. CD welders meet this challenge.

Nonetheless, selecting such a welder requires researching available types, which continue to evolve, especially in relation to the control systems supplied with the welders.

Three Types of Welders for Hot Stamped Welding

Fig. 1 shows waveforms of three welder types, all of which deliver excellent weld quality. As with Figs. 2 and 3, the green waveform depicts a mid-frequency direct current (MFDC) constant-current waveform with stable weld current. The red waveform depicts a standard CD welder yielding excellent welds by suppressing the heat effect to the work piece. The blue waveform depicts a variable-waveform CD welder combining the qualities of the MFDC and standard CD welders.

Conventional control systems charge the capacitive banks to different voltage levels to obtain the desired current during discharge from the capacitors. When the discharge occurs, the entire capacity of the stored charge dissipates. The full recharge time of the capacitors must be calculated into the weld time on each weld cycle.

Load variations are not compensated for during the welding process, as depicted in Fig. 2. The result: variation in welding current at the peak of the weld.

Weld current around the peak of the current waveform determines weld strength. Tailing current has no effect on the weld (Fig. 3). Without any type of current feedback in the conventional controls, exactly when peak current occurs remains unknown. Weld-current variation also can occur due to the lack of current feedback. Without feedback, the controls cannot compensate for the load variations during welding.Within the last 10 yr., newer control designs featuring active feedback systems have become available. These allow for current compensation during welding to correct current errors because of secondary-load variations, while the control itself creates a variable waveform that addresses issues that conventional capacitor discharge welders cannot. Fig. 4 illustrates the constant-current capability of the variable-waveform design.

With this new control design, users enter weld-schedule parameters with a keypad. Weld current and weld time are simple numeric entries. The weld-current entry, capable of turning off after reaching peak current, saves energy, which can remain stored in the capacitive bank. The result: energy-cost savings and cycle-time reductions due to not having to wait for the entire capacitive bank to recharge.

The variable-wave control becomes possible by utilizing an MFDC to control the discharge of the capacitive bank, combining the best of two worlds: fast welding and the precise control and stable weld strength through constant-current feedback offered by MFDC technology. The result: excellent and repeatable weld quality.