Program Nests Multi-Customer Laser-Cut Blanks, Parts to Cut Scrap Costs

June 1, 2015Comments

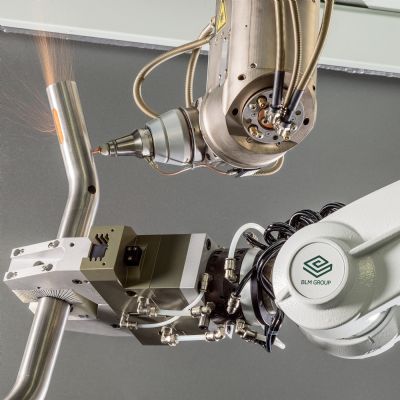

United Performance Metals, Hamilton, OH, has introduced Global Nest, an enhanced, multi-part, multi-customer laser nesting program. Administered through UPM, Global Nest maximizes material usage for laser-cut blanks and parts by matching up multiple parts and orders to achieve the greatest yield with the least amount of scrap, according to company officials, resulting in lower job costs and an improved path to just-in-time production. Customers who participate in the Global Nest program have their blank/part orders matched up with orders from other customers to maximize nesting, thereby lowering costs for scrap paid by each customer.

United Performance Metals: www.upmet.com

See also: United Performance Metals

Technologies: Software

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Software

SoftwareAtlas Tube Unveils HSS Connections Hub for Structural Engine...

Thursday, April 3, 2025

Software

SoftwareSandvik Set to Acquire Verisurf

Tuesday, March 11, 2025