Corporate Cost Center—Overseer of Two Sheetmetal-Fab Operations—Standardizes on Nesting Software

October 1, 2013Comments

Imscorp, Lincoln, NE, owns a pair of manufacturing companies, each with its own set of sheetmetal-fabricating equipment, and a variety of sheet-nesting software products used to plot cutting operations. The two companies: SourceOne, a custom contract manufacturer and powder coater, which also manufactures its own line of outdoor power equipment; and Bison, Inc., a manufacturer of sports equipment, outdoor site furnishings and custom gymnasium structures.

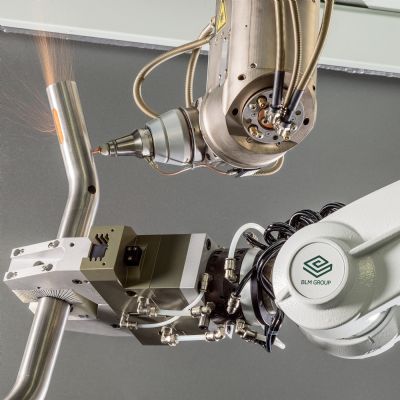

To make its sheetmetal-fabricating processes (laser cutting and turret-press punching) more cost-effective, Imscorp created a corporate cost center in a new facility to handle sheetmetal operations for both companies. It implemented a new MRP system, and then decided that to improve shop-floor efficiency and the companies’ freedom to select any brand of fabricating equipment, it would need to standardize on one nesting system and programming software.

Says Michael Kreuzberg, Imscorp production supervisor: “We did not want to have to use multiple software products to program different machines. We wanted one solution for everything.”

As its software solution, the firm selected Jetcam Expert, supplied by U.S. distributor NestOne Solutions, Duluth, GA, and purchased postprocessors for each of its machines. Kreuzberg was surprised at how quickly the system was up and running.

“I started as a programmer with no background in laser or turret CNC programming,” he says. “After we decided on Jetcam, there was a two-day installation and training program and we were producing parts within hours.”

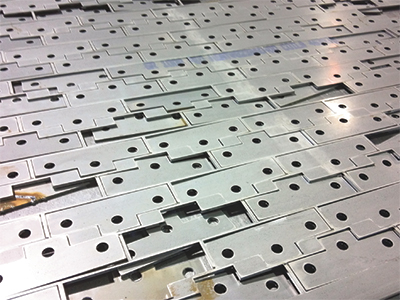

After going live, sheet utilization increased by 15 percent (or more, in some cases). And, more efficient nests means that fewer sheets must be loaded onto the machines. Jetcam also stores remnant sheets for future use, further reducing waste.

On-time delivery also improved. Says Kreuzberg:

“About half of our workload is for high-volume repeat orders, with the remainder being smaller jobs with short lead times. Since we can go direct from CAD file to nest very quickly, our captive shop lead times went from several months to weeks or days, and our smaller job-shop lead times went from weeks to days—even hours.”

Programming time also improved dramatically, with Imscorp taking advantage of Jetcam’s automatic component creation, tooling and nesting. CAD files automatically are imported using the software’s single-component automatic processing function, with component files being created, tooled and ready for nesting in seconds. And, the company takes information from its MRP system into Jetcam to combine orders of the same material and thickness.

“The system paid for itself in less than 8 months,” concludes Kreuzberg.

NestOne: 800/790-1640; www.nestonesolutions.comView Glossary of Metalforming Terms

See also: Nest One Solutions

Technologies: Software