Take, for example, the setting of parameters on a high-capacity metal-AM machine. There can be as many as 200 of these input parameters, all affecting part outcomes. Simple positioning of the part and the location of support structures could make a huge difference in getting it right and (more often than not) getting it wrong. Incorrect positioning can result in an energy-consumption increase of as much as 160 percent. Today’s reality is that perfecting the AM production of a bracket may take as long as two years.

And, getting it wrong is expensive. Consider that at current speeds, AM production of metal parts can take one to two days, so the cost of getting it wrong in terms of machinery, material and power is significant.

According to a December 2014 National Institute of Standards and Technology (NIST) report, a particular metal part made from aluminum alloys would cost approximately $3 via traditional manufacturing and approximately $29 via AM using selective laser sintering—a ten-fold cost increase.

For AM of plastics, the major costs are the machine cost per part, which is between 58.7 and 65.9 percent of the cost, and the material cost per part, which is between 29.1 and 30.4 percent. Energy consumption is another important factor in comparing the cost of AM, especially in terms of examining costs from cradle to grave.

Considerations for ‘First Time Right’

Four elements are essential in order to produce parts correctly from the start via AM:

- Material engineering—design optimal microstructures

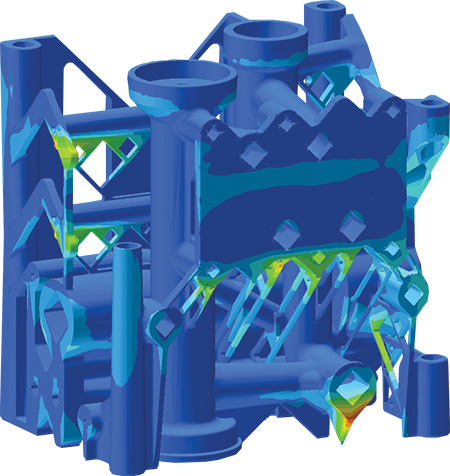

- Topology and shape optimization—design lightweight parts that retain structural integrity and potentially decrease part counts in sub-assemblies

- Process simulation—predict part deformation based upon part design, support-structure placement and machine conditions

- Part performance—check for the structural integrity of a part based upon both the design and the manufacturing process.

Much attention has focused on topology and shape optimization, with much expectation that strangely shaped yet structurally sound parts can be generated on a computer. What companies have come to learn is that just going from CAD to STL to machine is by no means sufficient. Manufacturers are realizing that, prior to tying up an expensive machine and delaying time to market, it is vital to first run a simulation of that process.

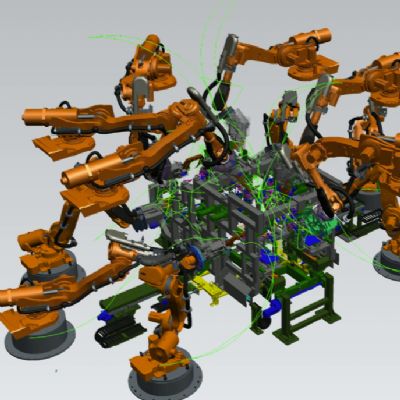

Successful simulation requires software tools that:

- Help the user position parts most appropriately for the machine parameters

- Create only the support structures substantially needed to minimize distortion and prevent build-job failure

- Provide analysis results quickly enough to guide the user’s decision-making

- Enable ease of use in the proper setup of manufacturing parameters, which are key to achieving repeatability

- Predict microstructures in the part

- Include simulation of the hot-isostatic-pressure process to reduce residuals stresses in the part, ensure that there is no porosity, and simulate the cutting process, which while removing the support structure may also remove needed stiffness.

A Superhero Will Emerge

So who is the engineer that can make sure that when the part is sent to the machine, it will come out perfect? Is it a CAD designer who will learn new skills in simulation and manufacturing? Is it as simulation analyst who needs to take on a greater role in initial part design? I think that this superhero will come from both areas, but one thing is clear: It has to be someone with a flexible mind and who thrives on learning new methods.

The Future is Bright

The vital signs all are positive. Machine speed will dramatically improve while machine and material cost will continue to decline. Simulation applications will evolve rapidly to ensure ‘first time right.’ In 1993, Apple introduced the Newton, the predecessor to the iPhone. It was a terrible failure. When the iPhone 3Gs were launched in 2008, Apple sold more than 1 million iPhones in just one weekend. Today, nearly 1 billion phones have been sold. So, it was not the hardware but the network speed and the applications that were key to the success. With AM, I believe we are leaving the Newton age and moving toward the iPhone age within the next 5 yr. With rapid advancement of predictive applications to guide the user, the next manufacturing revolution is upon us. 3DMP

See also: MSC Software Corp.

Technologies:

Around the globe, I see companies taking their best people and placing them into the new focus area of AM. There are budgets but not great experiences…yet. These companies are trying to gain enough experience to answer a multitude of questions:

Around the globe, I see companies taking their best people and placing them into the new focus area of AM. There are budgets but not great experiences…yet. These companies are trying to gain enough experience to answer a multitude of questions: