Substandard Slug Detection

To tackle the slug-detection challenge, the Schneider Electric team focused on an application employing a 45-ton press line fed with 3-in.-wide, 0.060-in.-thick cold-rolled steel strip. The material travels through 30 progressions in a two-out progressive die to produce the needed front and back parts.

Until implementing Brankamp’s sensing technology from Marposs in the targeted press line and die, Schneider Electric in Lincoln relied essentially on two systems for slug or stacked-part detection, according to Jake Smutny, the plant’s senior controls engineer.

Until implementing Brankamp’s sensing technology from Marposs in the targeted press line and die, Schneider Electric in Lincoln relied essentially on two systems for slug or stacked-part detection, according to Jake Smutny, the plant’s senior controls engineer.

“One system employed four stripper sensors—two in front and two in back along the stripper-plate edges,” Smutny says, “with each sensor providing about a 2-mm sensing range. Should the spring-loaded stripper reach a certain angle of incline, our press control would stop the press. The extended 2-mm sensing range caused problems. Double-stacking, even with 0.040- or 0.060-in.-thick part material such as with this application, sometimes resulted in enough ram force to smash down the material enough to successfully pass the sensors. But undetected pileups of multiple parts or slugs resulted in catastrophic punch and die damage, and downtime that we can’t afford.”

This sensing solution simply did not provide the needed precision to forestall trouble.

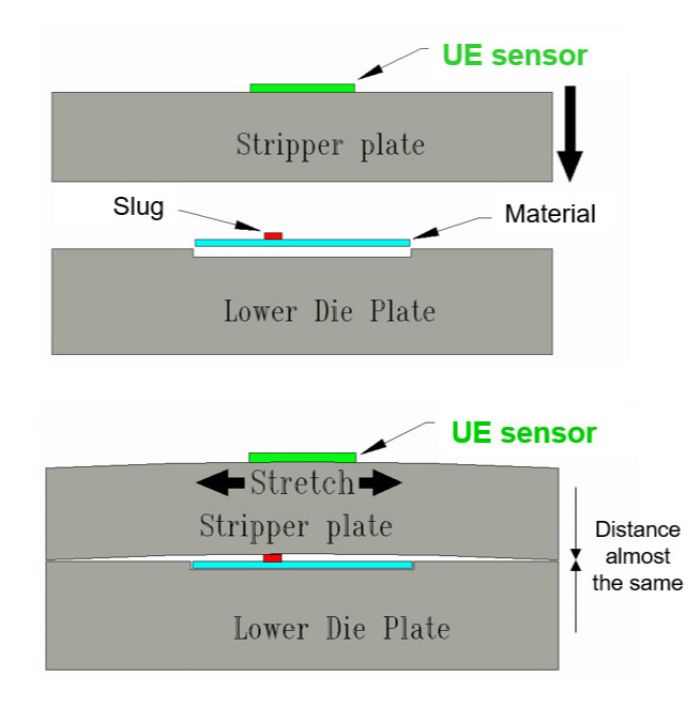

“With a slug or slugs in the center, the distance sensors, located on the edges of the stripper plates, had trouble detecting these conditions,” adds Joe Bortolameolli, Marposs product specialist. “The plates would bulge in the center, but the edges closed nearly all the way. The 2-mm sensors could not detect small gaps at the edges, or the edges had no gaps at all.”

“With a slug or slugs in the center, the distance sensors, located on the edges of the stripper plates, had trouble detecting these conditions,” adds Joe Bortolameolli, Marposs product specialist. “The plates would bulge in the center, but the edges closed nearly all the way. The 2-mm sensors could not detect small gaps at the edges, or the edges had no gaps at all.”

And, calibrating the old sensor setup proved to be a challenging and time-consuming process, according to Casares.

Detection also relied on tonnage monitoring.

“We know, obviously, that tonnage monitoring is designed for press protection and not to protect tooling or verify anything about the parts,” admits Smutny, “but on the floor, when we see a tonnage spike we stop the press. That might provide an indication of a pileup.”

While aware of technology available to address slug detection in the targeted application, production demands delayed implementation until about a year ago, according to Smutny and Casares. At that point, with a die under development in the toolroom, the team decided to upgrade sensing capability.

While aware of technology available to address slug detection in the targeted application, production demands delayed implementation until about a year ago, according to Smutny and Casares. At that point, with a die under development in the toolroom, the team decided to upgrade sensing capability.

New Setup Senses Stripper-Plate Stretching

More reliable and simplified slug detection arrived via Brankamp Ultra Emission (UE) monitoring technology from Marposs Monitoring Solutions GmbH. Strong UE piezoelectric sensors in this application, operating with each press stroke, measure not the gaps at the edges of stripper plates but the amount of stretch across the top of the plate, caused by a slug-buildup bulge. The sensors work by detecting electrical charges produced in solid materials—such as the stripper plate in this application—due to mechanical stress, in this case the stretched top surface of the plate.

“This technology picks up the distance change across the top of the stripper plate, which indicates stretching,” reiterates Bortolameolli, noting along with Smutny that integration with the press line’s upgraded inhouse controls was a relatively simple affair.

“The Brankamp standalone system monitors only the die, where we use a PLC that runs the press, monitors the feeder and monitors the parts count,” Smutny explains. “To integrate, we just employ a dry contact—which operates essentially as an on/off switch—between the Brankamp system and our control. Should the sensors detect a problem state, we simply disengage the clutch on our control side to stop the press.”

Installing this setup did require some work to install UE sensors in the die shoe. Anticipating these and other modifications, the Schneider Electric team, not wanting to halt current production, decided to task an inhouse tooling engineer, assisted by Marposs engineers, to help install the setup during development of a new die.

Ideal Answer to Production Pressure

Though Smutny and Casares don’t have before-and-after production numbers due to employing this slug-detection solution on a new die, they vouch for its effectiveness, and seek to employ the technology on other tooling as production breaks allow.

“With our capacity needs—including a 150-percent production increase over the past year—we’ve been trying to make more with less,” Smutny explains. “That’s where we receive advantages with this slug-detection system. We make fewer bad parts and don’t break our tooling. We do believe in the system, and we just need to bring our off-shifts up to speed so that we can feel comfortable running it around the clock.” MF

View Glossary of Metalforming Terms

See also: Marposs Corp.

Technologies: Sensing/Electronics/IOT

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Sensing/Electronics/IOT

Sensing/Electronics/IOTEliminating Pressroom Waste—One Walk at a Time

Manuel Resendes June 10, 2025

Industry 4.0 Applications in the Sheet Metal Forming Industr...

Eren Billur March 27, 2025

A constant challenge: ensuring proper part-material feed through dies and elimination of slug buildup—these problems quickly compound at such high run rates.

A constant challenge: ensuring proper part-material feed through dies and elimination of slug buildup—these problems quickly compound at such high run rates.