Sensors Have Needs

January 1, 2012Comments

A recent column explained what must occur during die setup to ensure proper function. Here we’ll focus on the needs of the die sensors. In the words of Aretha Franklin: R-E-S-P-E-C-T.

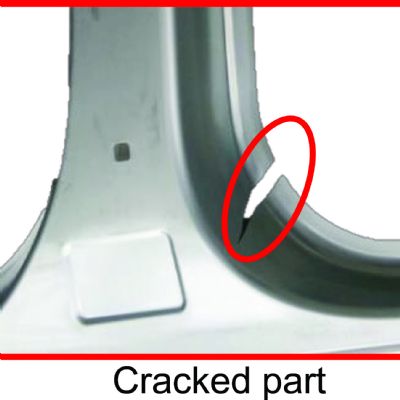

All too often I see electronic sensors mounted in setup that would unnerve a juggler, standing on a high wire during a hail storm. I’ve seen, for example:

• Photoelectric sensors mounted using homemade, flimsy sheetmetal brackets that easily become displaced as the die is moved in and out of the press;

• Proximity sensors and associated cabling bathing in oil-filled tooling pockets and channels;

• Feed-monitoring inductive proximity sensors whacked head-on by the end of the strip with each feed cycle;

• Connector junction boxes mounted on the edge of the lower die plate with multiple stab wounds from forklift drivers; and

• Photoelectric sensors with such severe skin and paint damage that their lenses not only are clouded but deeply scratched beyond recognition.

Certainly common sense should prevail in these examples, and remediate action taken. But no—the abuse continues in shop after shop. To quote playwright Arthur Miller, from Death of a Salesman: “Attention must be paid.”

Although electronic sensors can withstand a surprising amount of environmental calamities, including shock, vibration, fluids, over or under power-supply voltage and changes in target positions, I’ve never seen a category within a sensor’s spec sheets titled “Abuse Factor.” I am not kidding here—sensors simply are not designed to withstand poor mounting techniques or physical abuse. Sensors must be isolated as best as possible from physical attack by people and machines—please bury them within blocks of steel or aluminum.