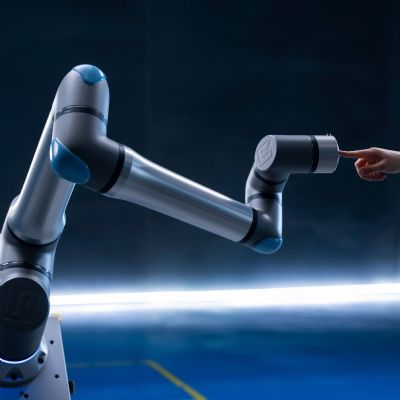

AI Vision System for Cobot Grinding and Finishing

February 28, 2024Comments

Kane Robotics reports that it has employed artificial intelligence (AI) in visual sensors to assess uneven surfaces and enable its collaborative robot (cobot) to make real-time adjustments in material-removal operations. Tasks such as sanding, grinding and finishing are accomplished thanks to a high-speed camera and AI-driven computer vision integrated with Kane’s Grit cobot package.

Kane Robotics reports that it has employed artificial intelligence (AI) in visual sensors to assess uneven surfaces and enable its collaborative robot (cobot) to make real-time adjustments in material-removal operations. Tasks such as sanding, grinding and finishing are accomplished thanks to a high-speed camera and AI-driven computer vision integrated with Kane’s Grit cobot package.

In operation, a human operator sets up the cobot and attaches the necessary tools for the weld-grinding process, then monitors and adjusts the process through a live custom interface. Next, AI takes over, according to company officials, who explain that, using the camera, the vision system “sees” uneven surfaces on a weld or seam. Via rapidly learning AI, the system alerts the cobot’s robotic arm and steers it accordingly.

“Thanks to AI, we now can teach a cobot to flexibly respond to changes in surfaces based on what it ‘sees’ through a camera attachment,” says Arlo Caine, Kane’s robotics engineer who spearheaded development of the Grit vision system.

Grit was first deployed at the Paul Mueller Co., a Missouri-based manufacturer of stainless-steel tanks and equipment, which needed a solution for seamlessly grinding welds on large steel tanks used in food and other industries. Grit’s AI software performs live object detection, ensuring accurate tracking even as the weld seam disappears during rotation. When faced with imperfect welds, the system proved it could be taught to detect variations and refine its grinding accuracy, according to Kane officials.

At the Paul Mueller Co., the Grit ST cobot performs the tedious and strenuous work of holding the grinder. The vision system manages the tiring task of tracking large seams for long periods. Then, a human operator sets and adjusts the force level most suitable to the chosen abrasive, grinding speed and number of grind passes to achieve the required finish.

While originally developed for weld grinding, the Grit vision system is compatible with various robotic components and customizable for diverse applications, from polishing aerospace parts to sanding furniture.

See also: Kane Robotics

Technologies: Additive Manufacturing, Finishing, Pressroom Automation