AI-Driven Remote Machine Monitoring

November 1, 2018Comments

MachineMetrics employed the IMTS 2018 stage to introduce MachineMetrics Service, an artificial-intelligence-driven remote machine-monitoring product designed for OEMs and other equipment providers. A predictive-analytics application on the MachineMetrics Industrial IoT platform allows service teams to remotely monitor and manage machine assets in the field and at customer sites in real time. Thus, say company officials, equipment manufacturers can transform their approach to service with the ability to see, understand and take action on their customer’s real-time machine data.

With this platform, including MachineMetrics’ cellular Edge device, equipment providers can enable remote access to monitor and assist with user operations to troubleshoot problems, resolve service events and monitor preventive maintenance tasks, all without leaving their office. Historical and real-time machine data allows equipment manufacturers to gain insight into customers’ equipment health and condition, identify new service opportunities with analytics and reporting, and predict and deliver early warning of potential equipment failures, and highlight elevated risk areas that lead to machine downtime.

In practice, an equipment provider, OEM or distributor installs the MachineMetrics Edge device on a new machine sold to a customer, or retrofits any machine in the field. MachineMetrics Edge has the ability to connect to the machine’s PLC and any additional sensors, allowing for data to be shared with the equipment provider. There’s no need to install on a customer’s internal IT infrastructure, as MachineMetrics Edge comes with included cellular support. Encrypted data then are streamed to the secure MachineMetrics cloud where the data are structured and aggregated to enable service teams to monitor analytics.

The MachineMetrics analytics engine will monitor any connected machine’s conditions and other manufacturing data points and initiate an action, such as sending text notifications when a limit is exceeded, or any other anomaly is detected related to the machine’s health.

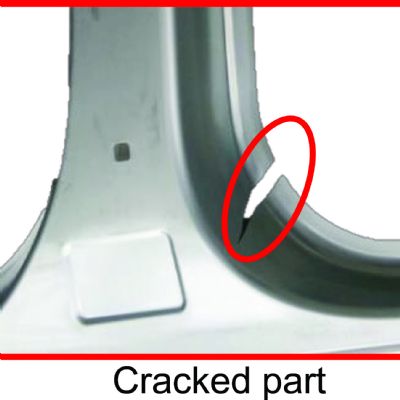

Using this data, equipment service providers can notify machine operators to change a tool before it breaks or even notify maintenance managers when an anomaly is detected that could lead to a breakdown. This ability can prevent thousands of dollars of equipment replacement costs and days of downtime, not to mention unearth new service opportunities, claim company officials.

Technologies: Sensing/Electronics/IOT

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Wintriss Introduces Hardware Solution for its ShopFloorConne...

January 14, 2025

Work-Instruction Software Enables Workers to Activate, Monit...

August 5, 2024

Quality Control

Quality ControlIndustry 4.0 Applications in the Sheet Metal Forming Industr...

Eren Billur Thursday, March 27, 2025

Sensing/Electronics/IOT

Sensing/Electronics/IOTFrom Data to Decisions: How Smarter Factories Will Shape Man...

Matthew Heerey Thursday, March 13, 2025