AGV-Mounted LADAR for Aerospace-Manufacturing Inspection

January 31, 2024Comments

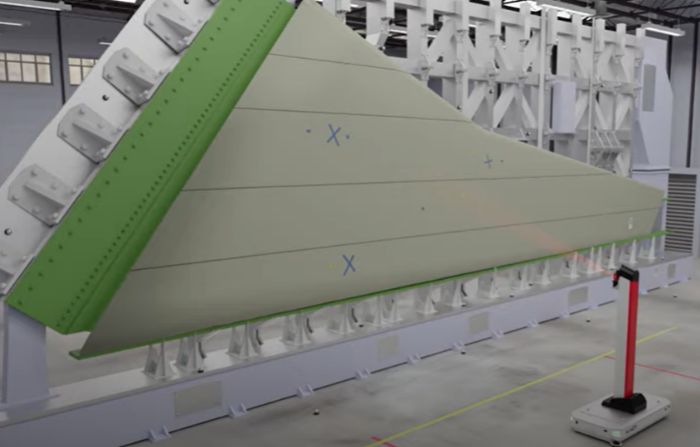

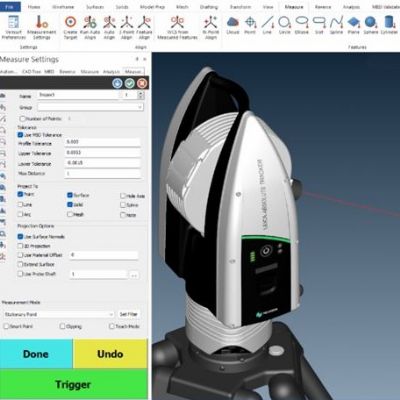

Automated Precision Inc. (API), a provider of metrology products, has introduced its Dynamic 9D LADAR mounted on an autonomous guided vehicle (AGV), designed for noncontact aerospace-manufacturing inspections.

Automated Precision Inc. (API), a provider of metrology products, has introduced its Dynamic 9D LADAR mounted on an autonomous guided vehicle (AGV), designed for noncontact aerospace-manufacturing inspections.

When integrated with an AGV, the 9D LADAR (LAser Detection And Ranging) offers flexibility and coverage across the manufacturing floor, navigating autonomously and adjusting its measurement height as needed. With a 25-m range and a scanning speed of 0.2 sec./cm², the noncontact system precisely captures dimensional and surface geometry data.

"The integration of our 9D LADAR with AGVs represents a significant leap forward in aerospace manufacturing,” says Joe Bioty, API president. “This innovation not only ensures the highest levels of accuracy but also streamlines operations, enhancing productivity and efficiency."

Key benefits include 3D accuracy of 25 μm + 6 μm/m; elimination of manual inspections; seamless integration into existing manufacturing processes and compatibility with third-party metrology software; and boosted productivity via rapid, precise and automated inspections that lead to increased measurement throughput.

See also: API Metrology

Technologies: Quality Control

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

Quality ControlVerisurf and Hexagon Sign Solutions Agreement

Wednesday, April 10, 2024

Nikon's AI Reconstruction Draws on Deep Learning to Deliver ...

Thursday, April 4, 2024

Quality Control

Quality ControlStarrett Appoints U.S. Territory Managers

Tuesday, October 17, 2023

Quality Control

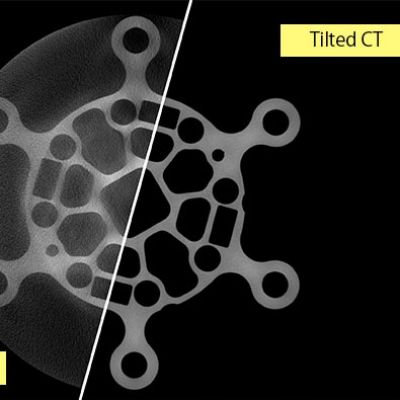

Quality ControlTilted CT from Nikon Improves X-ray Inspection of Flat Compo...

Wednesday, September 6, 2023