New, Quicker Destacker

July 1, 2015Comments

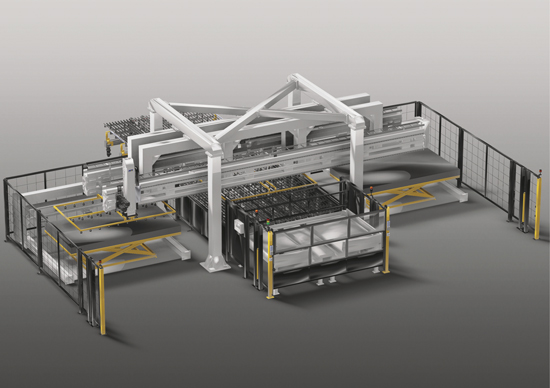

AP&T has introduced a new destacker, the model DST-DH, that meets the automotive industry’s demand for increasingly rapid production speed. The destacker, which reportedly can work twice as quickly as a conventional destacker, is designed to feed blanks for large vehicle parts (A-Class) such as doors, ceilings and sides.

• Capacity to 20/40 blanks/min. (single/double blanks)

• Capacity to 20/40 blanks/min. (single/double blanks)

• Processing of aluminum blanks without performance loss

• Blank size as large as 3500 by 2000 mm

• Processing of single, double and laser-welded blanks

• Automatic gripper-change system (optional)

• Automated setting of blank-separation unit

• Blank washer and lubrication unit (optional).

“The design was developed to correspond to the automotive industry’s demands for short cycle times,” says AP&T automation product manager Martin Sahlman. “It has been adapted for careful management of materials including aluminum.”

Video

Video