Sensing Aluminum Brings Challenges

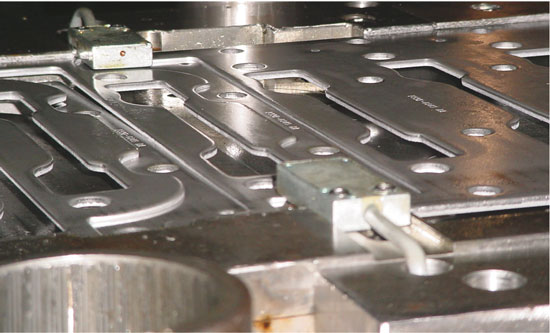

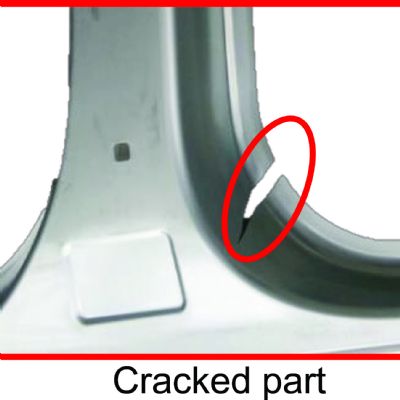

As automotive manufacturers ramp up their use of aluminum, metalformers must learn how to reliably sense aluminum components in automated stamping processes. While inductive proximity sensors have long been used for die protection and monitoring (feed), the ideal target for these sensors is mild steel—ferrous content in target materials ensures reliable detection in metalforming processes.

For sensing target materials other than mild steel, such as stainless steels and copper and aluminum alloys, metalformers opt for proximity sensors that feature correction factors—an adjustment calculation that dictates how the sensor must be placed in the tool, and how far a the sensor must be from the target material. These sensors, commonly called Factor One devices, incorporate a multi-coil design that enables them to sense all metal alloys—ferrous and nonferrous—at the same sensing distance. Factor 1 sensors will eliminate a few of the painful issues encountered when switching to aluminum strip or sheet.

Don’t Waste Time Threading Sensors

Threaded, tubular inductive proximity sensors have become the go-to standard in virtually every automated industry. However, in toolrooms and die shops this form-factor can be a pain. Die tools are heavy and complex forms, with moving parts and precision-cut tool steel. Why tap a 2-in.-deep threaded hole in the steel to accept a threaded tubular sensor? It’s no wonder that many dies have no sensors or limited sensor usage. The threaded tubular proximity sensor just wasn’t made for in-die sensing.

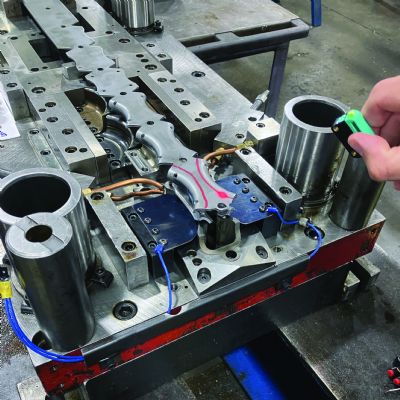

Inductively coupled wireless-connector systems send power across a small air gap and communicate sensor signals without any mechanical junction connection between components.

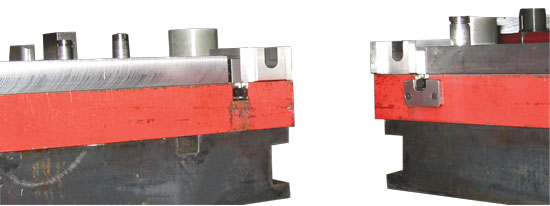

But there is a significant change happening in the design of inductive proximity sensors: flatpack housings, available in a variety of form factors and sensing ranges. A 20-mm square face can provide an impressive 7 mm of sensing distance, very similar to an 18-mm proximity sensor but with the depth of only 8 mm in some cases. Drop-in and bolt-down mounting allows for unparalleled versatility in sensing applications. Where a tubular style was completely unfeasible before, a flatpack sensor makes easy work for the die builder.

Eliminate Mechanical Connections for Quick Die Changes

While the use of umbilical connectors that energize sensors and carry signals between the die and the press controls will generally suffice, we often hear stories of fork trucks or cranes ripping out the umbilical and all the associated cables during die changes. This happens because an operator fails to disconnect the umbilical. The carnage can be breathtaking, leading to thousands to tens of thousands of dollars spent on repairs and, depending on tool usage, interrupting production.

For a better solution, stampers can integrate inductively coupled wireless-connector systems, to enable rapid die change; for use in joining die segments; to ease changeout of transfer arms; and for communication during transfer functions. This noncontact technology employs inductive coupling to send power across a small air gap and communicate sensor signals, without any mechanical junction connection between components. As a replacement to spring pins, commutator brushes and slip-rings, inductive coupler devices typically are resistant to coolants and lubricants and are IP67 rated. These units are as easy to use as proximity sensors and will operate maintenance-free—no mechanical wear. Pay Attention—Sensors Tell a Story Have you ever tried to diagnose an intermittent problem on a sensor, or tried to integrate an analog signal from a pressure sensor? Sometimes it would be easier if the sensor told us what was wrong or gave us the measurement value already calculated into the engineering units. Time is a valuable resource. Maintenance crews and operators must quickly find solutions to problems and keep equipment running. When using analog devices on a machine, it can be difficult to find a path for the shielded cable that does not incur noise from motors or other complications. A new technology, similar to USB but for industrial automation, is quickly gaining ground globally across automation control platforms: IO-Link (www.io-link.com, IEC 61131-9). This universal, smart and easy sensor/actuator interface allows a sensor to communicate like never before. Operating with a standard four-wire M12 tool cord, IO-Link devices can report diagnostics, provide measurement values digitally, and can be remotely programmed. IO-Link puts unprecedented data into the hands of operators, technicians, engineers and management. Manufacturing Intelligence and Traceability Manufacturing intelligence and cloud manufacturing are concepts that rely on every process and piece of equipment to report data. This can be a daunting task for those working with equipment that has been in place since before discos. In press shops, data flows from the dies/tools as well as from the movement of material through the facility. Technologies available to track important data include: • Paper tags: Believe it or not, hand-written paper tags wired to containers or taped to bins still find use. The least desirable means of tracking data, tags can fall off, become soiled, or the information written on the tag can be inaccurate to begin with. But, it’s an inexpensive option. • Barcodes: 1D and 2D barcode tags prove ideal for non-robust, clean and dry manufacturing environments. However, they require a centralized database and depend on line-of-sight. The chief complaint about bar codes: If the tag becomes scratched or soiled, it becomes difficult if not impossible to read. And, barcode tags can only be read, not written to. • Industrial RFID: This technology is robust and well-suited to harsh industrial processes. These systems can be serial, parallel or bus networked. The read/write of data is a proven technology that’s been used for decades. A disadvantage to RFID over the years has been the limited (<2 in.) read/write distance. However, recent developments in ultra-high-frequency (UHF) systems allow the reader and tag to be separated by as much as 20 ft. Finally, here are two breakthrough applications metalformers should be considering: Shut-Height Validation By strategically placing an RFID tag on a die, mounting a reader on the press and integrating a bit of control, stampers can reliably match a recipe for a particular shut height on the control to a die that has been presented to the press, preventing a potential crash. UHF Tags for Tracking Material Containers Carts and totes that move material within a plant or from a manufacturing facility to a customer often are expensive, intricate structures. This is especially true for containers used to transport critical components such car doors, hoods and truck decks. These high-value containers, often padded and secured with locking devices to prevent vibration in transit, seem to frequently become misplaced.

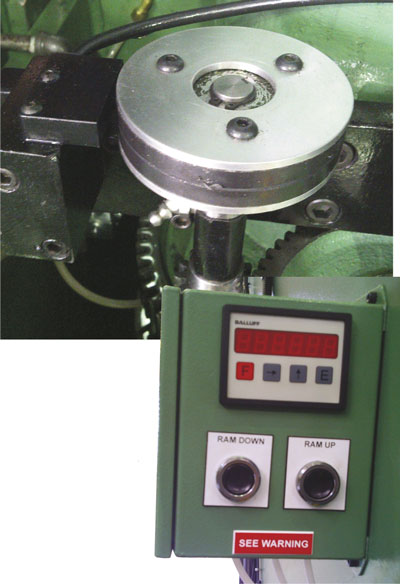

By strategically placing an RFID tag on a die, mounting a reader on the press and integrating a bit of control, stampers can reliably match a recipe for a particular shut height on the control to a die that has been presented to the press, preventing a potential crash.

View Glossary of Metalforming Terms

See also: Balluff, Inc.

Technologies: Pressroom Automation, Sensing/Electronics/IOT, Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Sensing/Electronics/IOT

Sensing/Electronics/IOTEliminating Pressroom Waste—One Walk at a Time

Manuel Resendes June 10, 2025