Four-Slide Tooling

April 23, 2019Comments

Most of the topics addressed in this column during the past 13 years cover metal stamping processes and dies. However, metal forming includes more than just stamping. Therefore, last month we addressed slide-forming processes. This month’s topic: four-slide tooling. And in coming months we’ll cover more metal forming processes and associated tooling challenges.

Stay tuned.

Essential Elements

|

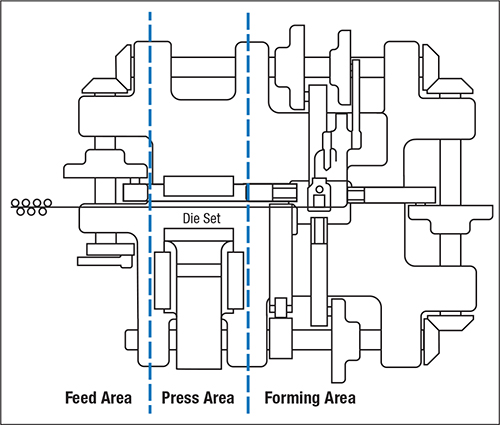

| Fig. 1—Main elements (areas) of a four-slide machine. |

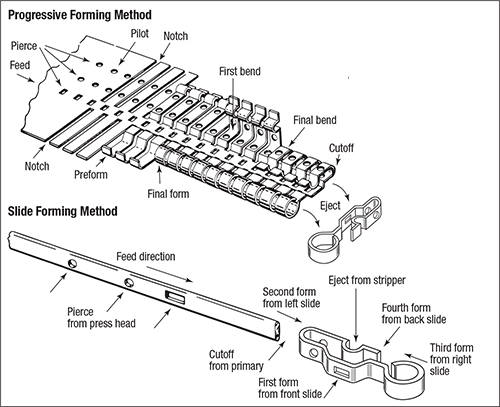

Carrier-tab lengths vary by part design, material thickness and/or processing method but should not be less than three times the strip thickness. Blanks separated by a straight cutoff or that have matching shapes at each end, as well as most wire forms, do not require a carrier tab.

The press area at the center of the machine enables punching and sometimes light forming of a strip in one or more die stations. The distribution of punching loads among the die sets should balance as much as possible. Positioning high-tonnage operations like gutting and coining in the center of the die sets is a prime objective.

|

| Fig. 2—When compared to progressive die-stamping for the same part design, the four-slide process exhibits simplicity of tooling while providing an economic advantage. Source: PMA Design Guidelines, 4th Edition. |

A cam-operated stock clamp advances through the front tool to hold the bank material against the forming mandrel throughout the forming cycle. Timing the stock clamp to hold the blank against the mandrel a few degrees of machine rotation before cutting occurs provides optimum control of the blank through the forming process. Depending on design, the part may be formed on the same plane as the feed line, or partially formed on the feed plane and then moved to a lower position on the forming mandrel, where additional forming steps occur during the next cycle.