Uniformity Labs’ Stainless-Steel Powder Qualified for Desktop Metal Shop System

September 15, 2022Comments

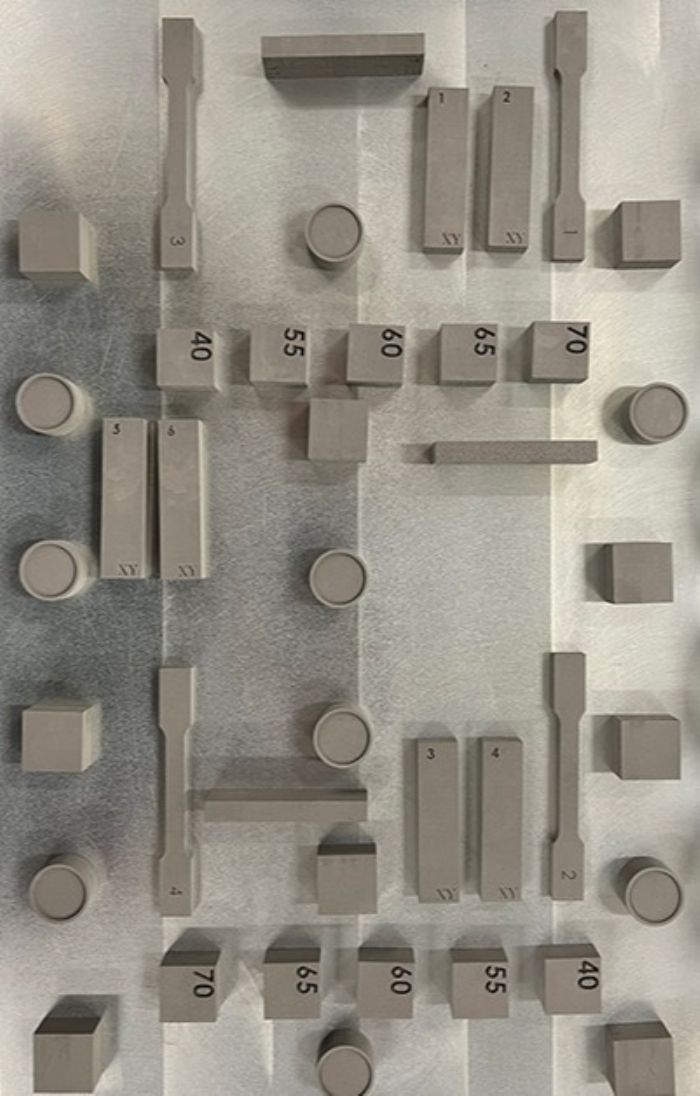

Uniformity Labs announced the availability of its ultra-low

porosity 17-4PH stainless-steel powder for the Desktop Metal Shop Pro binder jetting

platform. The powder reportedly delivers superior material properties as well

as sintered-part geometric accuracy, process yield and print uniformity at high

throughput.

Uniformity Labs announced the availability of its ultra-low

porosity 17-4PH stainless-steel powder for the Desktop Metal Shop Pro binder jetting

platform. The powder reportedly delivers superior material properties as well

as sintered-part geometric accuracy, process yield and print uniformity at high

throughput.

A low and reportedly stable shrinkage allows for manufacture via binder jetting of large parts, to 10s of centimeters in length, with process stability reportedly enabled by the low-cohesion, low-porosity powder that repeatably spreads uniformly across the build bed. Expect reduction to 50 percent in linear shrinkage relative to competitor materials and repeatable delivery of 99-100-percent final-part density. One benefit of low shrinkage: increased printer throughput due to greater use of the build volume. And, the highly flowable powder, according to company officials, further improves throughput by allowing repeatable rapid layering, with a net throughput benefit of approximately 50 percent relative to non-Uniformity powders on comparable platforms.

17-4 PH, a martensitic precipitation-hardened stainless steel is known for corrosion resistance and high strength and hardness levels, especially when heat treated. 17-4 PH can be heat treated to various hardness and toughness levels, allowing users to customize the postsintering properties of the alloy to suit a variety of applications, such as chemical processing, manufacturing machinery and food processing.

See also: Desktop Metal, Inc., Uniformity Labs

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Expect Another Virtuoso Performance—Metal Stamping Technolog...

Brad Kuvin December 11, 2024

Management

ManagementGE Appliances Makes $490-Million Investment at Its Louisvill...

Monday, June 30, 2025