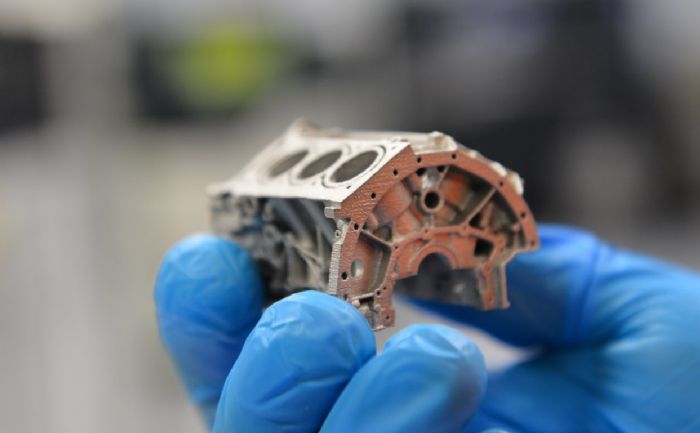

Until now, some aluminum alloys could be 3D printed using lasers, but the process reportedly is slower than the one developed by Ford and ExOne. The new process is expected to increase Ford’s efficiency by allowing the company to affordably produce complex parts uniquely designed for additive manufacturing (AM), which enables size and weight reductions, part consolidation and performance improvements.

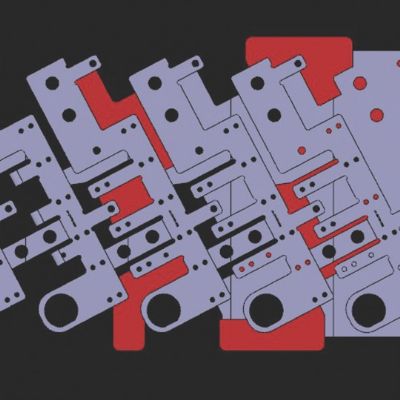

Binder jetting employs a digital file to quickly inkjet a

binder into a bed of powder particles such as metal, sand or ceramic to create

a solid part, one thin layer at a time. When printing metals, the final bound

metal part must be sintered in a furnace to fuse the particles together. The

heating process reinforces the strength and integrity of the metal, and though

the stainless steel-sintering process is well-understood, achieving high

densities greater than 99 percent is an industry breakthrough for aluminum,

according to ExOne officials.

“This is a breakthrough in making 3D-printed and sintered parts for the auto industry,” says Harold Sears, Ford AM technical leader. “While the 3D printing process differs greatly from that for stamping body panels, we understand the behavior of aluminum better today, as well as its value in lightweighting vehicles. High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to create complex parts with aluminum that previously weren’t possible.”

ExOne final part density is now 97 percent, in line with MIM

and better than investment castings, report company officials, with infiltration

no longer required for high density. This technology commonly achieves a weight

reduction of 30 to 50 percent for parts redesigned for binder jetting. Other

reported binder jetting benefits: sustainability, with less than 10-percent

waste; and lower capital and operating costs than other AM processes.

See also: Desktop Metal

Technologies:

Binder jet 3D printing has become a viable option for volume production of metal-alloy parts, according to ExOne officials, commenting on the company’s ability to 3D print standard metal injection molding (MIM) powders into fully dense parts. ExOne’s systems reportedly now can print more than 20 metal alloys, including 316L, 17-4PH and M2 tool steel.

Binder jet 3D printing has become a viable option for volume production of metal-alloy parts, according to ExOne officials, commenting on the company’s ability to 3D print standard metal injection molding (MIM) powders into fully dense parts. ExOne’s systems reportedly now can print more than 20 metal alloys, including 316L, 17-4PH and M2 tool steel.