Manufacturing Aluminum Alloys With 3D Printing

August 10, 2020Comments

The trend toward replacing or complementing subtractive manufacturing with additive manufacturing (AM) processes shows no signs of letting up. Example: the growing interest in using 3D printing in metalworking, where flooding the metal part with coolant leading to metal removal is a commonly used subtractive process.

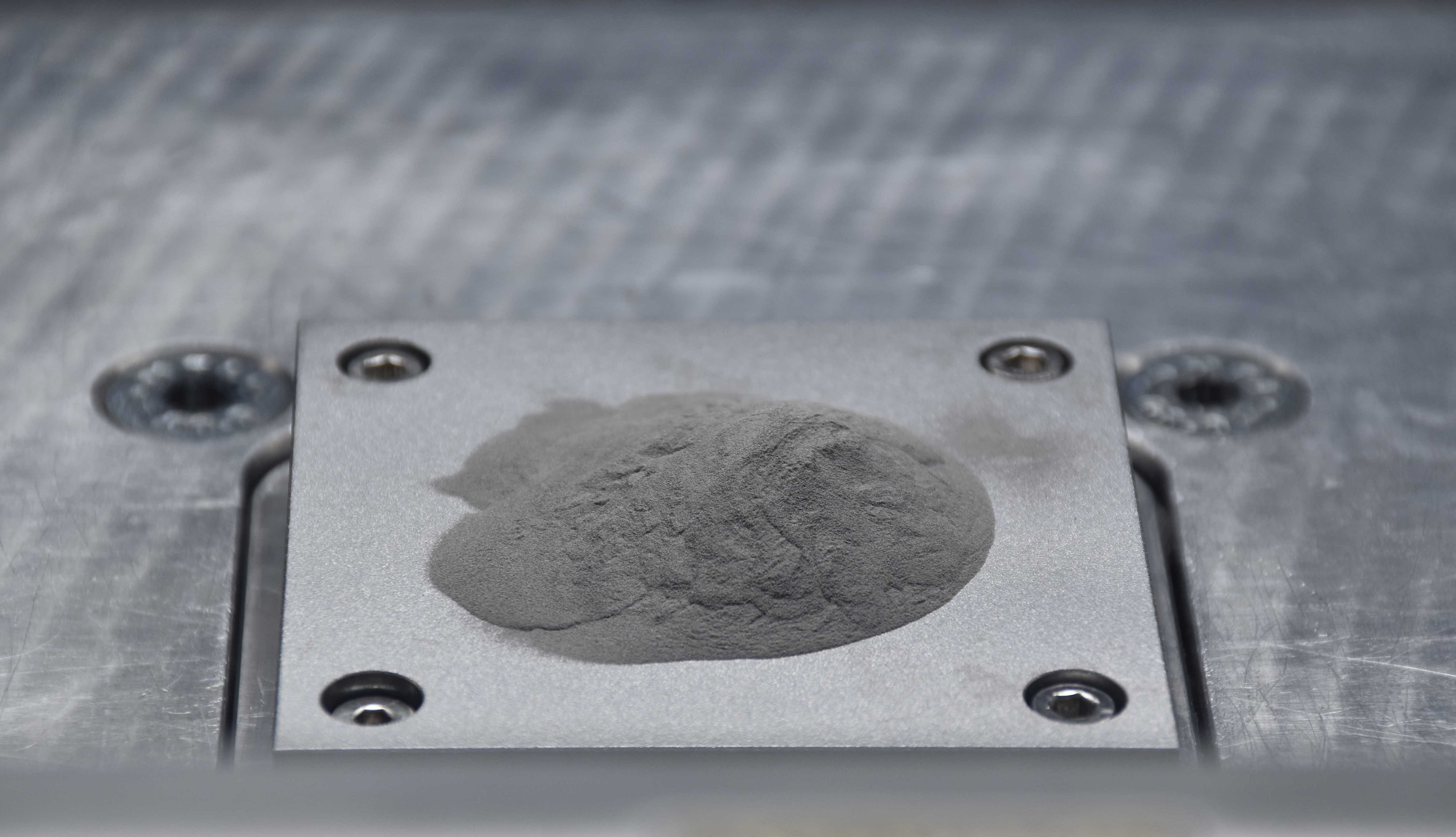

In contrast, 3D printing systematically builds metal components by adding metal layers. “Building a metal structure layer by layer, using an electronic beam to melt alloy powders, is analogous to welding,” says Hunter Martin, technical staff member at HRL Laboratories, LLC, in Malibu, CA.

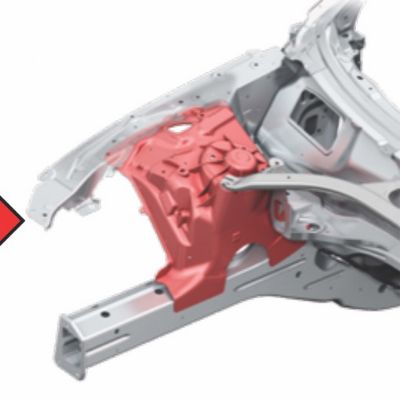

Fig. 1—3D printing of Type 6000 and 7000 aluminum alloys has been achieved by the addition of hydrogen stabilized zirconium particles to the powdered aluminum alloy prior to processing. Figure courtesy of HRL Laboratories, LLC.

However, that’s not to say that alloy powders, especially aluminum alloys, are necessarily amenable to welding. Finding a procedure to 3D print aluminum alloys represents a good demonstration platform for other non-weldable alloys.

“Aluminum alloys offer the worst-case scenario for 3D printing because they exhibit a large solidification range that is difficult to weld,” Martin says. “We consider Type 6061 aluminum to be the most difficult alloy to weld, with 7075 a close second.

“In attempting to weld one Type 7075 aluminum plate to another,” he continues, “large cracks form between the materials, leading to microstructures with columnar grains and cracks present in successive print layers. The resulting metal suffers from inferior physical and mechanical properties related to strength, fatigue life and fracture toughness.”

The microstructure of these materials contains dendritic structures similar to snowflakes. These structures form due to a breakdown at the solid-liquid interface.

The challenges described by Martin recently drove research and development of an approach to 3D print with 6000 and 7000-series aluminum that lead to less material shrinkage, with the expectation that this will apply to other alloys.