Metal Properties: Uniform Elongation

November 30, 2022Comments

The elongation value found on metal certs relates to its ductility to the point of fracture. Certs show this as “elongation at fracture” or “elongation after fracture,” depending on the test method used. These values differ from the focus of this article—uniform elongation.

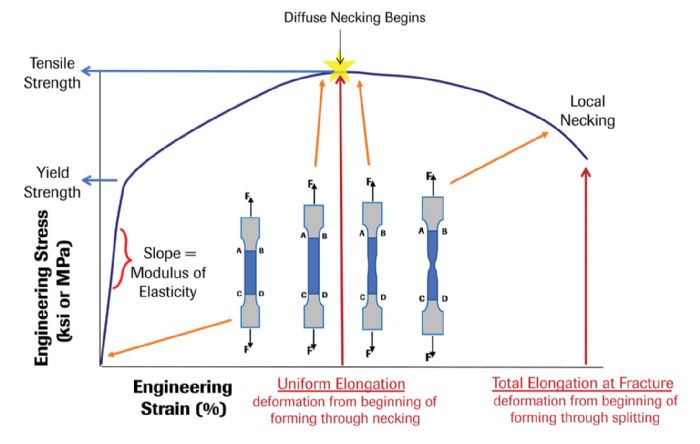

During a tensile test, the dogbone-shaped sample undergoes a reduction in the cross-sectional width and thickness as its length increases in tension. A stress-strain curve plots the material’s response to the applied load and resulting elongation. The shape of this curve shows a peak at the maximum engineering stress, called the tensile strength. This characteristic shape results from the opposing effects of the work hardening and the reduction in cross-sectional area that occurs when the sample deforms in tension.

During a tensile test, the dogbone-shaped sample undergoes a reduction in the cross-sectional width and thickness as its length increases in tension. A stress-strain curve plots the material’s response to the applied load and resulting elongation. The shape of this curve shows a peak at the maximum engineering stress, called the tensile strength. This characteristic shape results from the opposing effects of the work hardening and the reduction in cross-sectional area that occurs when the sample deforms in tension.

The beginning of the curve slopes upward due to work hardening effect outweighing that from the cross-sectional area reduction. Starting at the tensile strength, reduction in the cross-sectional area of the test sample overpowers the work hardening and the slope of the engineering stress-strain curve decreases. A diffuse neck forms at this maximum engineering stress, typically found in the middle of the sample in the reduced-width portion of the gauge length.

The elongation where the maximum stress occurs is called “uniform elongation.” In a tensile test, uniform elongation is the percent increase in gauge length occurring at peak stress relative to the initial gauge length. For example, if the gauge length at peak stress measures 59 mm and the initial gauge length was 50 mm, uniform elongation is (59-50)/50 = 18 percent.

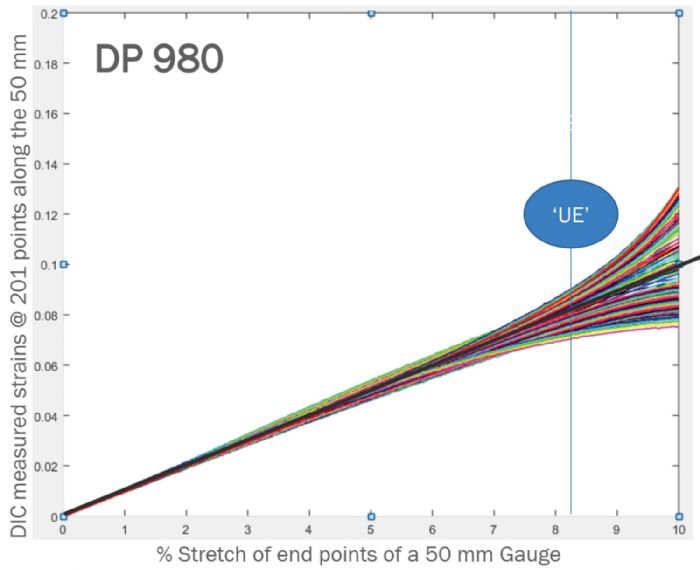

Accurate metal forming simulation requires capturing the stress-strain relationship at all strains, but a tensile test alone provides valid data only through uniform elongation. Beyond this value, simulation engineers assume either a certain behavior, or more accurately rely on the results from bulge testing or other methods to capture the correct response.

Accurate metal forming simulation requires capturing the stress-strain relationship at all strains, but a tensile test alone provides valid data only through uniform elongation. Beyond this value, simulation engineers assume either a certain behavior, or more accurately rely on the results from bulge testing or other methods to capture the correct response.