Over time, better predictive forming models helped stampers learn how to address some of these challenges. First-generation AHSS grades such as dual-phase, complex-phase and ferritic-bainitic steels continue to find use in automotive applications.

Improvements to AHSS, including the development of 3rd Gen AHSS and press-hardenable steels for hot stamping have emerged to provide additional relief from those difficulties. MetalForming spoke with spokespersons from three major steelmakers—Nucor, Cleveland-Cliffs and ArcelorMittal—to learn how steelmaking has evolved to produce AHSS with an improved strength-ductility balance to empower better metal forming results.

1. What are the new steels and their steelmaking methods?

J.B. Chronister, senior director, business development, Cleveland-Cliffs: AHSS’ high tensile and yield strengths must be balanced with the need for formability. Some of the strength of the earlier grades had to be traded for formability while maintaining strength for crash performance. Three grades became very popular for lightweighting over the last 15 yr. The 780-MPa tensile strength steel has some level of formability. It is an intermediate grade between the dual-phase 590 MPa, which may not provide the required strength needed for automotive structural components, and the 980-MPa grade that has higher strength but lower formability.

J.B. Chronister, senior director, business development, Cleveland-Cliffs: AHSS’ high tensile and yield strengths must be balanced with the need for formability. Some of the strength of the earlier grades had to be traded for formability while maintaining strength for crash performance. Three grades became very popular for lightweighting over the last 15 yr. The 780-MPa tensile strength steel has some level of formability. It is an intermediate grade between the dual-phase 590 MPa, which may not provide the required strength needed for automotive structural components, and the 980-MPa grade that has higher strength but lower formability.

A 3rd Gen AHSS has been developed that combines better formability than previous generations to resolve formability problems. It isn’t quite as strong but is more formable, while retaining a lot of the characteristics that stampers need in terms of product consistency. The Nexmet 1200 product is one such product, representing very high strength with a much-improved formability level than other grades of this strength.

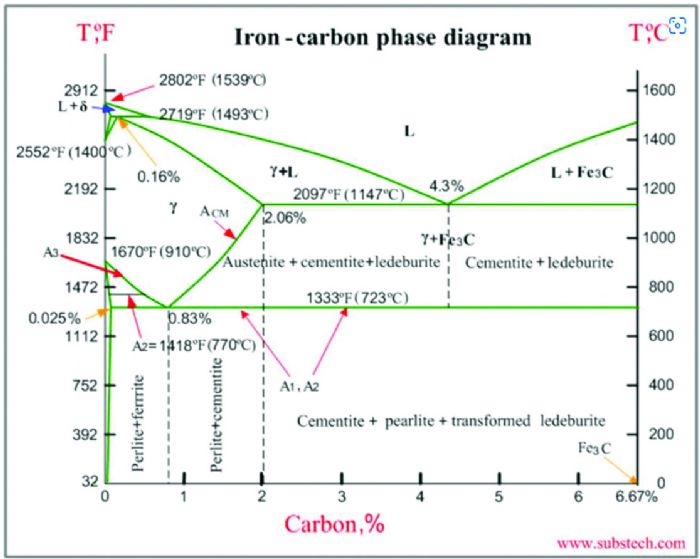

Steelmaking chemistry control in blast-furnace and basic-oxygen-furnace technologies has advanced over the years with better processing equipment and better process modeling to produce 3rd Gen AHSS.

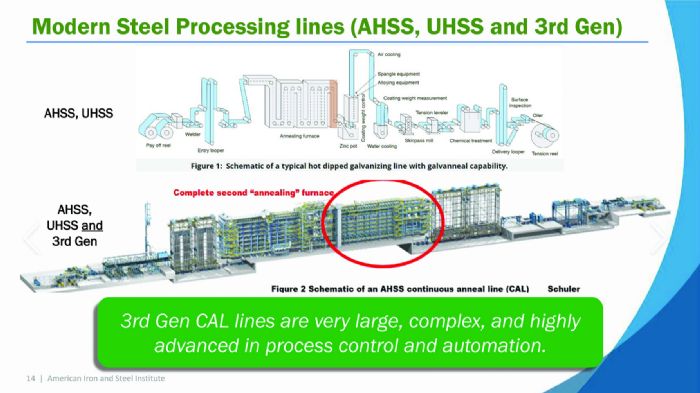

Cleveland-Cliffs makes its Gen 3 AHSS with a different composition than other mills might to achieve high-strength/high-formability properties. Some of that is related to its melt shops’ material process capability, and the thermal mechanical processing that it goes through. Differences also can be related to new developments in finishing operations and the coating lines. Improved heat treatment controls on the coating line allow for coated steel sheet to be annealed inline, then quenched and tempered to develop high strength with improved formability. This capability is critical for the better formability in 3rd Gen AHSS.

Cleveland-Cliffs makes its Gen 3 AHSS with a different composition than other mills might to achieve high-strength/high-formability properties. Some of that is related to its melt shops’ material process capability, and the thermal mechanical processing that it goes through. Differences also can be related to new developments in finishing operations and the coating lines. Improved heat treatment controls on the coating line allow for coated steel sheet to be annealed inline, then quenched and tempered to develop high strength with improved formability. This capability is critical for the better formability in 3rd Gen AHSS.

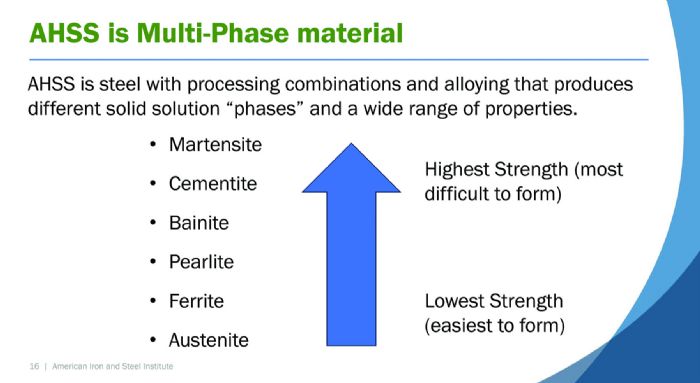

Dean Kanelos, market development and product applications manager, Nucor: Steel makers have developed many new grades with different microstructures than conventional steels. Nucor has developed several high-strength multiphase steels and is developing 3rd Gen dual-phase steels with high formability/ductility to meet future demands for improved formability at higher strengths.

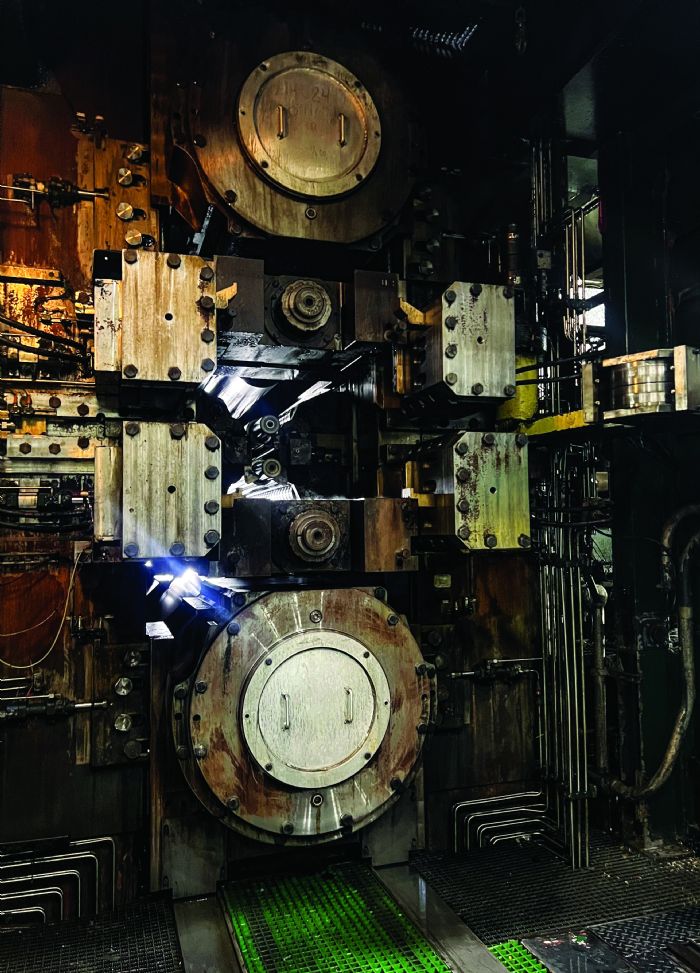

Nucor recently built new facilities and implemented new manufacturing methods, with more being built, to make a variety of new AHSS. These grades require significantly more rolling force. In turn, this requires the use of more powerful rolling mills to efficiently roll these steels to gauge. Nucor’s new specialty cold mill complex at its Arkansas sheet mill was built with a supported six-high reversing mill capable of cold-reducing AHSS steels to gauge with more force and significantly fewer passes than conventional reversing mills. Several new AHSS grades require upgraded galvanizing lines with improved heat treat capabilities to be galvanized or galvannealed. Many grades require a continuous annealing line with rapid quench capability and additional furnace capacity to attain the unique thermal processing needed to develop the desired microstructures.

Nucor recently built new facilities and implemented new manufacturing methods, with more being built, to make a variety of new AHSS. These grades require significantly more rolling force. In turn, this requires the use of more powerful rolling mills to efficiently roll these steels to gauge. Nucor’s new specialty cold mill complex at its Arkansas sheet mill was built with a supported six-high reversing mill capable of cold-reducing AHSS steels to gauge with more force and significantly fewer passes than conventional reversing mills. Several new AHSS grades require upgraded galvanizing lines with improved heat treat capabilities to be galvanized or galvannealed. Many grades require a continuous annealing line with rapid quench capability and additional furnace capacity to attain the unique thermal processing needed to develop the desired microstructures.

Nucor recently built a new flexible galvanizing line that can operate as a continuous annealing line or a galvanizing line that can coat and heat treat the new AHSS grades, with an annual capacity of approximately 500,000 tons. Currently, Nucor is building two more galvanizing lines with this capability.

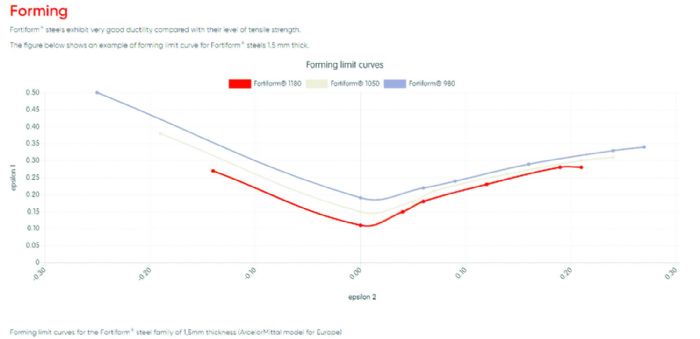

Bala Krishnan, director, global R&D, ArcelorMittal: As their names and specifications imply, the new 3rd Gen grades have higher formability at a given strength level, irrespective of whether they are hot-stamped (such as Usibor and Ductibor) or cold-stamped (such as Fortiform and multi-phase MP).

Bala Krishnan, director, global R&D, ArcelorMittal: As their names and specifications imply, the new 3rd Gen grades have higher formability at a given strength level, irrespective of whether they are hot-stamped (such as Usibor and Ductibor) or cold-stamped (such as Fortiform and multi-phase MP).

The most modern steel-making methods are the result of several process improvements. ArcelorMittal made multimillion-dollar investments in sophisticated heating processes, precise annealing, rapid quenching and controlled-cooling capabilities. In addition, steam injection, uniform coating and post treatments add versatility to these grades. These include developing pre-phosphated steel that lowers the friction coefficient to enhance material movement through the binder and improve paintabilty; special alloy coatings that double corrosion protection; and treatments that accelerate the heating rate on hot-stamped steel. This is not an all-inclusive list; other treatments are proprietary.

More improvements are under development and will be available over the next few years with the planned transformation in steelmaking to reduce carbon emissions for greater sustainability using state-of-the-art technology.

More improvements are under development and will be available over the next few years with the planned transformation in steelmaking to reduce carbon emissions for greater sustainability using state-of-the-art technology.

2. What are 3rd Gen steel grades’ significant material-property improvements?

Krishnan, ArcelorMittal: Modern innovations have prioritized manufacturability as much as delivered weight savings at the best value possible. This represents a huge shift from previous generations that prioritized lightweighting exclusively, leading to manufacturability challenges.

These cold-stamped Fortiform and multi-phase MP 3rd Gen steels provide additional weight reduction thanks to their higher mechanical properties than conventional AHSS while retaining the same formability. For example, the 3rd Gen, high-formability 980-MPa steel has the same total elongation as that of the 2nd Gen 590-MPa product with good bake-hardening.

Kanelos, Nucor: Property characterizations of new Gen 3 AHSS include higher ductility at higher strength levels but also higher n-value (work hardening).

Nucor has developed several complex-phase and multiphase grades that have unique microstructures, providing excellent stretch to flanges, resistance to shear fracture and global formability. They also have excellent weldability and fatigue performance.

Chronister, Cleveland-Cliffs: Early grades of AHSS have a relatively large gap between yield and tensile strength. What does that mean? It is the inherent nature of the product to have high springback. 3rd Gen AHSS grades have low yield-to-tensile strength ratios, which improve forming characteristics while supporting load requirements in thin-gauge components. While the 3rd Gen AHSS are not as formable as an extra-deep-drawing steel, which has 40% or higher elongation, they have more than three times the strength with as much as 20% elongation.

As with other grades of AHSS, 3rd Gen steels also work-harden very rapidly during forming.

As with other grades of AHSS, 3rd Gen steels also work-harden very rapidly during forming.

3. How do 3rd Gen AHSS improve stamping and metal forming? How do they address dimensional conformance, springback and edge cracking?

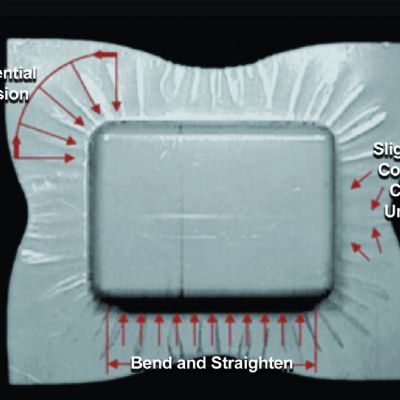

Kanelos, Nucor: 3rd Gen AHSS offer several advantages. They allow for deeper drawing, more complex forming and improved edge stretching. They enable metal formers to produce more complex components than they could before that are stronger, stiffer, and lighter in weight—without a significant cost increase. They do not necessarily reduce springback, but dies can be better designed to compensate for springback by factoring in the material’s higher elongation.

Chronister, Cleveland-Cliffs: The more formable 3rd Gen grades are capable of a more severe bend. Material thickness plays into how much the steel can be bent and how the tooling interacts. When that 20% elongation in 3rd Gen AHSS is designed to be in the right places, stampers can form the part needed and achieve the final geometry.

Krishnan, ArcelorMittal: ArcelorMittal has changed the mindset about specifying material properties. Gone are the days when the only material properties that customers could specify were as-delivered. Now metal formers and fabricators specify stamped-product surface characteristics, and ever-increasing hole-expansion requirements on all products to mitigate edge cracking, enable multi-step stamping and improve post-laser-welded formability. Some of the specific properties endow higher hole expansion, better flatness, better bendability, tighter coating-weight control, tighter property variability, coatings that prevent surface oxidation on hot-stamped products, or a combination of them that may not be explicitly mentioned in the specification, but can take on complex geometries.

4. What are the ramifications on tooling, die and part designs of 3rd Gen AHSS? Does metal forming equipment, tooling and material-handling equipment need to be altered to use these new steels? What do stampers need to know to use these newer grades?

Kanelos, Nucor: Even with 3rd Gen AHSS’ greater formability, press forces must increase to stamp AHSS, which may require larger presses and higher cushion pressures. The dies experience higher forces which cause greater wear and galling—and that requires more-frequent die maintenance. Metal formers may need to modify die tooling to accommodate the increased forces, including the use of heat treatments, die inserts in heavy wear areas to minimize maintenance time and cost, tougher tool steels, die coatings such as PVD, and surface treatments such as nitriding. They need to modify bead geometries to compensate for the increased springback and to prevent wrinkling, excessive stretching and cracking. They may need to change die lubricants due to increased loads and higher temperatures.

Kanelos, Nucor: Even with 3rd Gen AHSS’ greater formability, press forces must increase to stamp AHSS, which may require larger presses and higher cushion pressures. The dies experience higher forces which cause greater wear and galling—and that requires more-frequent die maintenance. Metal formers may need to modify die tooling to accommodate the increased forces, including the use of heat treatments, die inserts in heavy wear areas to minimize maintenance time and cost, tougher tool steels, die coatings such as PVD, and surface treatments such as nitriding. They need to modify bead geometries to compensate for the increased springback and to prevent wrinkling, excessive stretching and cracking. They may need to change die lubricants due to increased loads and higher temperatures.

Stampers need to understand the properties and characteristics of these new steels, allowing for deviation in gauge and mechanical properties. Good global and local material modeling is important to minimize excessive recutting of dies. Material cards of the grades should accurately represent the steel being stamped.

Chronister, Cleveland-Cliffs: 3rd Gen steels, like any AHSS, work harden very rapidly during forming. That creates heat in the dies and the challenges that come with that. Heat buildup must be managed due to higher loading. The heat generated can constrain productivity. Production rates also may need adjustment to control the heat and keep it from being a problem. Stampers can manage that with lubricants matched to higher friction and temperatures. Tooling must be planned and maintained with improved material choices.

Metal formers can manage residual springback and work hardening through different die configurations, edge-strain limitations and use of laser blanking. The use of combination bead designs in the die helps control material flow. Springback control is manageable in almost all cases with improved die-face compensation and die modeling.

Edge quality is very critical in all steel products, and cutting-tool quality is key to maintaining excellent edges that maximize the stretch and forming.

Increased maintenance likely is necessary to maintain good tolerances and surfaces.

Metal formers should invest in entry and exit equipment designed specifically to manage these higher-strength steels, whether it’s a stronger tension leveler, a temper mill with higher loading capability, or more robust unwinding and rewinding equipment.

Many different forming-simulation programs do a good job, but as anybody who’s been in the business long enough knows, no computer simulation can represent everything that could possibly happen. Variations can occur throughout the manufacturing process, so there’s no substitute for actually getting material into the plant and going through the pre-production tryout phase to ensure that the steel is going to work well in your equipment and process.

Many different forming-simulation programs do a good job, but as anybody who’s been in the business long enough knows, no computer simulation can represent everything that could possibly happen. Variations can occur throughout the manufacturing process, so there’s no substitute for actually getting material into the plant and going through the pre-production tryout phase to ensure that the steel is going to work well in your equipment and process.

Krishnan, ArcelorMittal: Strangely, the answer to this question is not only technical. All of the players are experts in their own field. The steel makers, stampers, tool- and diemakers, and engineers all must communicate their needs and challenges—especially during the early stages of the transition to these grades.

Any new technology requires new learning in areas that were not previously focused on. Die wear, higher friction and die temperatures all have to be carefully tamed. Metal formers should recalculate press tonnages.

5. What are the new grades’ best applications?

Krishnan, ArcelorMittal: This new generation of grades was driven by—and are specifically tailored for—automotive programs. Basically, these grades have been created for improved crash protection, especially with the high-gross-weight electric vehicles (EVs) coming to the market—not only to protect the passenger, but also the battery.

Their applicability in the non-auto area is limited, although we can see some cases when lightweighting or abrasion resistance drives the need. Any application that requires lightweighting and part consolidation with good corrosion resistance as well as good manufacturability and assembly all are targets. The sky is the limit. If less-capable grades can meet these criteria, they likely will be used to save cost.

ArcelorMittal is having similar detailed conversations for applications in the energy and industry sectors where this sophisticated knowledge could be deployed appropriately. For example, the development of specialty steel grades for hydrogen-fuel-cell vehicles is poised to bring improvements there.

ArcelorMittal is having similar detailed conversations for applications in the energy and industry sectors where this sophisticated knowledge could be deployed appropriately. For example, the development of specialty steel grades for hydrogen-fuel-cell vehicles is poised to bring improvements there.

Kanelos, Nucor: The best applications for the new AHSS grades include structural chassis components such as frame and roof rails, rockers, A and B pillars, cross members, bumper beams, and EV battery-box components. This would also include control arms, engine cradles and rear cradles.

Non-automotive applications for AHSS steels have been slower to come; however, as demand for sustainability and energy efficiency increases, other markets are using some of these steels. They include heavy equipment, agricultural equipment, and Class 8 trucks and trailers.

Chronister, Cleveland-Cliffs: Many automotive applications are being redesigned with new grades for better energy absorption and intrusion protection. Examples include door rings, structural members in all areas of the vehicle and exposed items.

High-strength steels are being used in many non-automotive applications for construction, solar-field structures and military applications, to name a few.

6. Considering that AHSS has been developed, at least in part, to reduce carbon emissions via lightweighting, are you doing anything on the manufacturing-process side to reduce carbon emissions?

Chronister, Cleveland-Cliffs: Cleveland-Cliffs has worked to reduce carbon emissions with massive investments such as the hot-briquetted-iron-production unit in Toledo, OH; by replacing some of the coke used for iron reduction with natural gas; and by using higher scrap rates to stretch hot-metal use and reduce emissions. More efficient use of energy and generation of its own electricity or steam by using off gases for combustion also reduce the mill’s carbon footprint.

Cleveland-Cliffs has increased its sourcing of sustainable energy such as solar and wind generation. In the future, it will ramp up the use of hydrogen (H2) to support more process decarbonization. The blast furnaces are ready to use H2 once it becomes available. Massive green-energy sources and new technology will be needed on an industrial scale to ensure that the H2 is not a major source of greenhouse-gas emissions.

The company is considering carbon-capture systems, a high capital investment, for large facilities to help limit CO2 emissions.

One approach alone will not work for every location and mill, but a combination of several of these improvements will allow Cleveland-Cliffs to continue its sustainability journey.

Kanelos, Nucor: Nucor has several projects underway to reduce carbon emissions in its steel manufacturing. For example, it has partnered with ExxonMobil to develop carbon capture, utilization and storage at Nucor’s direct-reduced-iron manufacturing facility in Louisiana. Also, Nucor has invested in Electra in the development of carbon-free ironmaking, as well as NuScale Power in the development of small modular-reactor nuclear technology.

In addition, new facilities and equipment at several facilities allow Nucor to produce high-strength and AHSS more efficiently with a wider range of capabilities. These initiatives are designed to significantly reduce production carbon emissions.

Krishnan, ArcelorMittal: The company’s approach to reducing carbon emissions is to combine best practice with existing technologies to develop solutions that enable it to meet its targets. We are doing this by exploring technologies which utilize:

- Clean power to fuel hydrogen-based ironmaking, direct electrolysis ironmaking and other low-emission technologies

- Circular economy sources of carbon energy such as bio-based and plastic waste from municipal and industrial sources, and agricultural and forestry residues

- Fossil fuels with carbon capture and storage to transform existing iron and steelmaking processes into low-emission pathways.

AcelorMittal recognizes that issues of the environment and sustainability are bigger than any one company. That is why it works alongside other stakeholders to create a culture that supports investment in smarter, more sustainable steels that provide long-term solutions for future infrastructure and products. The 2023 Altair Enlighten award for Sustainable Process recognized its achievements in this area.

Beyond 3rd Gen

Great gains, achieved by extraordinary efforts, have been made by steelmakers to balance strength and ductility. Gains likely are to continue, incrementally at least. Hot stamping, for example, has resolved some challenges with UHSS.

“ArcelorMittal has developed new press-hardening grades, such as Usibor and Ductibor, for the hot stamping process to resolve the Achilles heel of springback in UHSS,” ArcelorMittal’s Krishnan says.

“Nucor is working on the development of a press-hardenable steel with improved properties that does not require a coating and has good high-temperature oxidation resistance,” Kanelos says. “This eliminates the need for shot blasting after forming.”

Cleveland-Cliffs’ Chronister adds, “In the last 20 yr., hot stamping has gone from zero to very widespread use, and that is an answer for 1300- and 1500-MPa-grade steels. Ultralume is our grade family of press-hardening steel products. Heating the blanks and bringing them into a press makes them more formable—but there are some limitations. As with any of these grades, thermal management is key and extra process controls must be in place to manage the heating and quenching process.”

More is to be developed—and learned—as to what the new steels can do. MF

View Glossary of Metalforming Terms

See also: Nucor Corp., ArcelorMittal USA Inc., Cleveland Cliffs Tek & Kote

Technologies: Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsAvoiding the 7 Deadly Sins of Stamping: Part 5 Metal-Flow Pr...

Art Hedrick Tuesday, February 11, 2025

Materials

MaterialsManaging the Speed of Change

Peter Ulintz Monday, February 10, 2025

Advanced high-strength steels (AHSS) were developed to provide strength at thin gauges to facilitate lightweighting in automotive applications. Their high strength improves safety performance by increasing energy absorption during a crash, enabling stronger, lighter structures with better passenger-cabin intrusion protection than before.

Advanced high-strength steels (AHSS) were developed to provide strength at thin gauges to facilitate lightweighting in automotive applications. Their high strength improves safety performance by increasing energy absorption during a crash, enabling stronger, lighter structures with better passenger-cabin intrusion protection than before.  The first generations of AHSS facilitated great gains in lightweighting but came with brutal challenges for metal formers. They were more difficult to uncoil, slit, blank, stamp, trim and weld, with stubborn springback from the residual stress that occurs after forming. Without compensation for these new properties, this resulted in wrinkles, tears and distorted parts. In addition, the steels were somewhat cost-prohibitive, which limited their use.

The first generations of AHSS facilitated great gains in lightweighting but came with brutal challenges for metal formers. They were more difficult to uncoil, slit, blank, stamp, trim and weld, with stubborn springback from the residual stress that occurs after forming. Without compensation for these new properties, this resulted in wrinkles, tears and distorted parts. In addition, the steels were somewhat cost-prohibitive, which limited their use.