Material Selection: The Rest of the Story

December 27, 2019Comments

Automotive bodies include increasing amounts of higher-strength steels and aluminum alloys to address the challenges of improving fuel economy and safety while reducing tailpipe emissions. Stamping and assembly hurdles are tackled regularly, with the impact of these materials choices reaching beyond the metal forming community and affecting the entire supply chain.

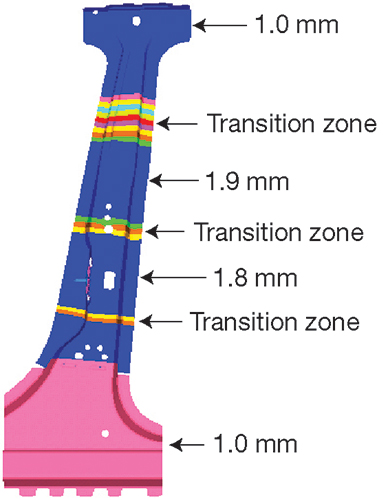

Fig. 1—The Jaws of Life evolved to tackle advanced automotive body structures in extraction of vehicle-crash victims.

Producing higher-strength steels requires upgrades at the steel mill. The molten steel requires tighter control of alloying chemistry. Hot and cold rolling demand greater rolling mill forces, placing greater strain on mill stands. Achieving improved thickness tolerances requires upgrades in roll profiling and maintenance schedules. Producing advanced high-strength steels (AHSS) often necessitates significant capital expenditures due to the thermal cycle needed to achieve the relevant microstructures.

These grades, once produced, often must undergo additional processing. Shape issues such as flatness, waves and coil buckles require upgraded leveling equipment, especially when working the highest-strength materials. Slitting or blanking may be particularly challenging. In addition to the issues associated with increased material strength, cut edges of advanced grades, with their engineered microstructures, behave differently than those of other grades. Optimal clearances and cutting steels likely will need upgrades or else premature failure will occur.

Cutting-knife sharpness, alignment, maintenance and capabilities demand careful consideration even outside of coil processing shops. After the first form operation, metal stamping companies trim away the binder and addendum, with the scrap collected, bundled and shipped to a scrap processor. These processors further cut, shred and bale these steels. By mid-decade, automotive usage of steel grades with tensile strength of at least 100,000 psi is expected to grow five-fold.

Crash Access

The high strength of alloys used for passenger-cage parts promotes greater occupant safety but doesn’t eliminate the risk of a crash. When crashes do occur with passengers trapped inside, rescue personnel use power tools, including the Jaws of Life (Fig. 1), to cut through sections of the passenger cage such as the B-pillar or roof rail.

Webinar

Webinar