Automotive Steels—Online Technical Resources

May 1, 2012Comments

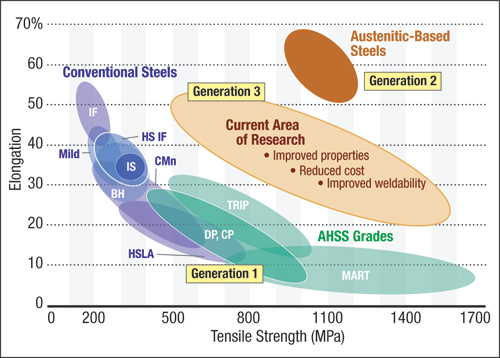

Starting in the 1960s, high-strength low-alloy (HSLA) steels were the hot topic for making vehicles stronger and safer. Over the next two decades the maximum strength of HSLA steels increased, while lower sulfur content reduced the number and size of inclusions that limited stretching and bending. Still, some labeled these steels a mundane commodity.

From the 1960s through early 1990s, new information about these automotive steels and their capabilities developed slowly. Knowledge was transferred through seminars, textbooks and magazines. Access usually was limited and often expensive. Today, a vast amount of information about new automotive steels is available at no cost via Internet downloads, webcasts and magazine subscriptions—most of them free. Here we describe some of the better sources of information.

The most comprehensive, free document is AHSS (Advanced High Strength Steel) Application Guidelines, available at www.worldautosteel.org. The document comprises six sections:

1) General description

2) Forming, including discussion of properties, springback and hydroforming

3) Joining—including resistance welding, laser welding and adhesive joining

4) Glossary—definitions from WorldAutoSteel and the Auto/Steel Partnership

5) References—sources of figures, graphs and technical papers

6) Appendix—details of case studies conducted by the Auto/Steel Partnership

Information in AHSS Application Guidelines compares these new steels to HSLA and conventional low-strength steels. For example, the section on springback applies to all steels. Some higher-strength steels are designated by yield strength or tensile strength, depending on global location and strength values. For example, the document uses the format HSLA 350/450 that designates type of steel, yield strength (MPa)/tensile strength (MPa). The SAE has proposed a similar format of DP 600T/350Y in SAE J2745—Surface Recommended Practice for Advanced High Strength Steels. AHSS Application Guidelines also includes typical engineering and true stress-strain curves for the different types and grades of higher-strength steels compared to mild (AKDQ) reference steel.

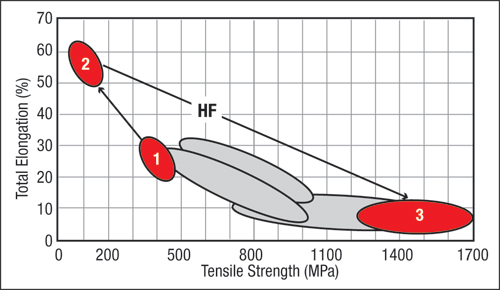

Fig. 2—Segments of the Fig. 1 curve can be used to describe hot forming and other steel processes. Courtesy of WorldAutoSteel.