Tool Coatings Described

October 1, 2008Comments

IonBond, Madison Heights, MI, details its lineup of thin-film PVD, PA-CVD, CVD and TD coating technologies in a new brochure, Stamping & Forming Applications: High Value Solutions. Advantages from using the coatings, according to company officials, include downtime reduction, enhanced productivity, improved tool life, improved part finishes, reduced maintenance costs and reduced lubrication usage, with the coatings serving as environmentally friendly substitutes for hard-chrome plating.

The company, as noted in the brochure, has significant experience in bundling the coatings with other services such as vacuum heattreatment, flame hardening, ion nitriding, ferritic nitrocarburizing, cryogenic treatment and polishing.

IonBond: 248/398 9100; www.ionbond.com

View Glossary of Metalforming Terms

See also: IHI Ionbond Inc

Technologies: Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsChemcoaters Launches InterCoat ChemGuard for Body-in-White S...

Tuesday, April 6, 2021

Materials

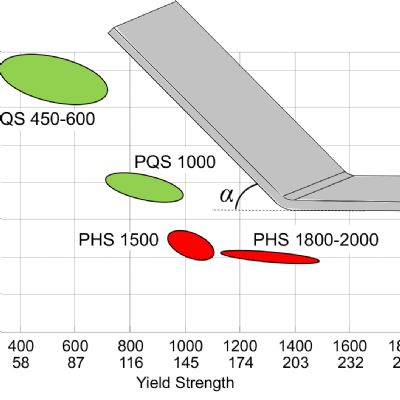

MaterialsHeating Helps Forming, Part 1: Hot Stamping of High-Strength...

Eren Billur Wednesday, July 29, 2020

Materials

MaterialsStamping High-Strength Stainless? Coating is a Tool Lifesave...

Lou Kren Wednesday, July 29, 2020