Forming also permanently deforms the sheet metal, strengthening it through a phenomenon known as work hardening. Certain applications may call for applying a stress-relief heat treatment to the formed component to reduce the strength and improve ductility.

Processing variables make it impossible to state that one metal alloy or one composition always will be stronger than another. We typically associate higher carbon and manganese content with higher-strength steels, but there are many routes to increase strength. In addition, some aluminum grades are stronger than steel grades, but they gain that strength from different processing routines and rarely are they intended for the same applications.

Stiffness

Stiffness, an elastic response, represents the measure of a formed component’s ability to return to its original shape after removing an applied load. It is a function only of the elastic modulus, thickness and part geometry; microstructure and mechanical properties have little impact on component stiffness.

The elastic modulus—the slope of the initial linear portion of a stress-strain curve obtained during tensile testing—represents the resistance of a material to elastic deformation under load, which is fully recoverable upon removing the load. The yield strength marks the deviation from this linear region and indicates the start of permanent plastic deformation.

All steel grades have approximately the same elastic modulus, yet these grades come in many different strengths depending on alloying compositions, rolling practices and heat treatments. Similarly, all aluminum alloys have approximately the same elastic modulus, approximately one-third that of steel. This difference in elastic modulus means that for the same sheet thickness and part design, a part made from an aluminum alloy will deflect three times as much as a steel part subjected to the same loading conditions. Achieving the same stiffness requires changes to either the thickness or part geometry, or both.

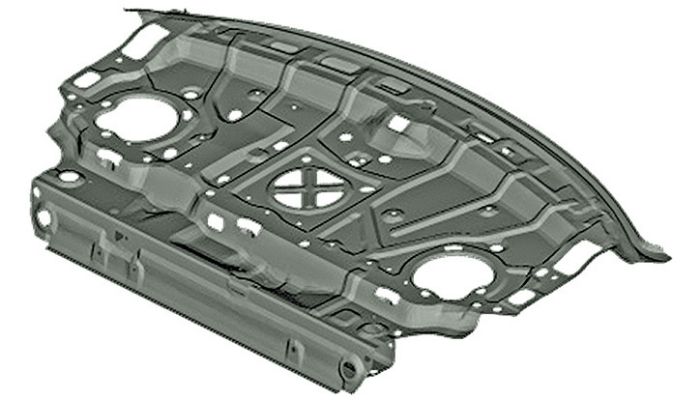

Part design and geometry also influence stiffness. Just as putting a crease in a sheet of paper changes it from flimsy to rigid, automakers use character lines to increase stiffness in flat Class A panels. Beads or stiffening ribs in body-structure members increase stiffness, but the sheet metal must have sufficient formability to accommodate the additional geometry in the stamped part. This becomes more challenging in components stamped from lower-modulus materials having lower formability than steel.

Thickness (t) has an outsized effect, as stiffness scales with t3. With aluminum having one-third the modulus of steel, manufacturers negate the stiffness effect by designing aluminum parts 45-percent thicker than similarly designed steel parts. Some parts will still see weight savings even at this increased thickness because aluminum is one-third the density of steel.

Application-Dependent Considerations

Manufactured parts have different functions and constraints. Strength factors into the design of certain parts, while stiffness is the dominating consideration in others. All stampings permanently deform the incoming flat stock, indicating that the stresses exceed the material yield strength, with parts designed to ensure that the applied stresses fall below the tensile strength. These are strength considerations.

Automotive-body-structure stiffness influences handling and noise, vibration and harshness. Design changes, such as switching from a C-channel frame to a closed section, improve stiffness, as does the reduction of spacing between cross members and the use of panels with deeper draw depths or greater curvature. In these cases, designers must consider the characteristics and forming capabilities of the selected sheet material.

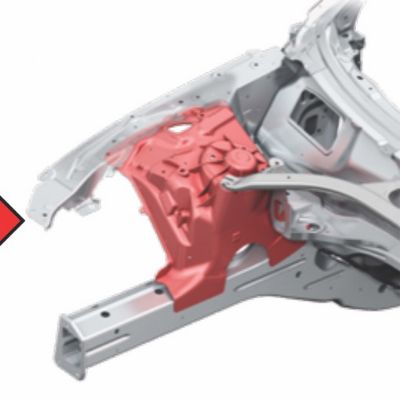

Parts used for crash-energy management in automotive applications typically are stamped from the highest-strength materials available that still are formable into the targeted shape. In contrast, when forming skin panels, while strength is important since it influences dent resistance, stiffness is the primary consideration. Here, automakers typically specify the thinnest sheet that meets the stiffness criteria for the skin-panel design.

Body panels stamped from aluminum often include contours and feature lines to increase stiffness, to counteract the reduced material stiffness as compared to higher-elastic-modulus steel grades. MF

Note: Schaeffler will speak about higher-strength steels at the PMA/MetalForming magazine Metal Stamping and Lubrication Technology Conference, March 29-30, 2022, in Cincinnati, OH.

Industry-Related Terms: Alloys,

Aluminum Alloy,

Curvature,

Draw,

Ductility,

Forming,

Lines,

Plastic Deformation,

Tensile Strength,

Thickness,

Work HardeningView Glossary of Metalforming Terms

See also: Engineering Quality Solutions, Inc., 4M Partners, LLC

Technologies: Materials

Strength, a property of the sheet material and a function of composition and processing, is independent of part design. Carbon, for example, is an efficient strengthener, where only 0.10 percent can dramatically increase strength. Processing comes in many forms, including rolling in the production mill to plastically deform the sheet and increase material strength. After cold rolling, a heat treatment known as annealing relieves internal stresses and reduces the strength while restoring ductility.

Strength, a property of the sheet material and a function of composition and processing, is independent of part design. Carbon, for example, is an efficient strengthener, where only 0.10 percent can dramatically increase strength. Processing comes in many forms, including rolling in the production mill to plastically deform the sheet and increase material strength. After cold rolling, a heat treatment known as annealing relieves internal stresses and reduces the strength while restoring ductility.