Metallurgical Lab Sets Experi-Metal Apart

“With PHS, we are not just a stamper, but a heattreater,” says King, explaining the decision to construct the lab.

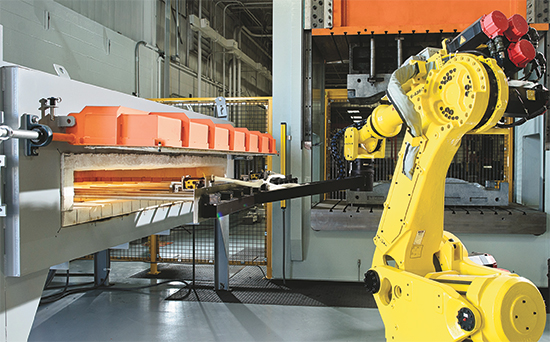

As he notes, to achieve the proper martensitic characteristics for hot stamping, managing and repeating the entire manufacturing cycle is critical. King provides an outline of a typical hot stamping “recipe” used by Experi-Metal: the cycle initiates when the steel blank is picked up via robot transfer from the material load station then placed into a preheated oven. The oven must maintain a closely controlled environment, and the steel must be heated to a specific temperature then soak for a specified window of time. The heated steel then transfers again via robot from the oven to the press. Here it is formed within the approximate 9 to 12-sec. cycle time while maintaining a dwell under tonnage for a specified timeframe until the material is cooled or quenched to proper temperature.

“To ensure that the material achieves the proper martensitic properties, we must then test it,” King says. “The first piece of material in a part run routes immediately to our onsite met. lab where an Experi-Metal technician performs an extensive battery of tests including tensile, yield, elongation, surface hardness and micro-etch, using our 500x microscope equipped with a digital camera and photo package. Our technician then can immediately verify that test results meet the proper material characteristics.”

Most prototype stamping facilities don’t have this capability onsite, so they must send samples out to offsite labs. Results may take overnight or longer.

“With our lab,” says King, “we have material results prior to producing parts. By testing the first part in the morning, we won’t run parts all day, and then, if the characteristics aren’t correct, have to scrap an entire day’s worth of production—or worse yet run the risk of nonconforming products reaching the customer. Upon receiving approval from the Experi-Metal met. lab, production ensues.”

Additional met.-lab testing is performed at various intervals throughout the production run.

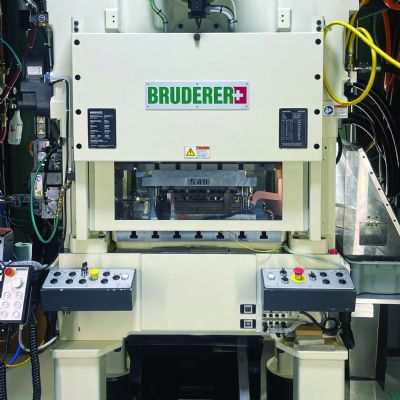

Press Cell Allows for Testing of Other Processes

Heavily involved in hot forming, Experi-Metal is experimenting with related processes, such as aluminum warm forming, which also can be performed in the new press cell. Whereas steel heats to about 1700 F for hot forming, aluminum typically heats to approximately 600 F during warm forming. Both processes find use in imparting strength to the materials, and aluminum should continue trending upward in automotive applications as challenges related to this notoriously difficult to shape material are tackled.

“With aluminum warm forming the intent is to use 2000- and 7000-series alloys as opposed to 5000- and 6000-series alloys,” says King, explaining the general direction of industry research. “The 2000- and 7000-series alloys are much stronger and achieve much-improved crash-test results, but are more difficult to form. It should also be mentioned that encouraging test results have been achieved when forming 5000- and 6000-series alloys into more complex geometries with deeper draw configurations while using warm-forming techniques. In general, forming trials thus far have yielded some good results for us as well as promising test results for our customers.”

Down the road, the company may explore titanium hot forming, in the same press cell, for aerospace applications.

With Experi-Metal’s signature press cell humming along and advancing the boundaries of unique process technologies while meeting the company’s varying metalforming needs, King expresses satisfaction with the choice of equipment.

“We’ve committed a significant investment and a large chunk of real estate to house this cell, and we are very happy with it,” he says. “This has been one of those projects where we began with a vision and then ended up with something even better than we had dreamed possible.” MFView Glossary of Metalforming Terms

See also: Macrodyne Technologies, Inc., Experi-Metal Inc

Technologies: Materials, Pressroom Automation, Stamping Presses