The ERP-taskforce leader should have the authority to make decisions on behalf of the organization. Additional taskforce-team members should create a well-balanced team that includes accounting, sales, IT, engineering and general operations. Enlist experienced people who are trusted and respected by others in the company. Strong problem-solving, teambuilding and communication skills will help build an effective taskforce.

The genesis for needing an ERP system is the desire for better business results. Selecting an ERP system impacts all critical areas of manufacturing, from quote to cash and everything in between. Many companies rely solely on IT resources for researching and selecting an ERP system, and often prioritize technical factors ahead of business factors. Without input and leadership from other areas of the business, the focus can end up on the technology rather than on the business goals.

Create an ERP Strategy

An ERP strategy serves as a roadmap throughout the implementation process. A manufacturer’s ERP taskforce should evaluate and make decisions in these critical areas:

- Define the top priorities. Trying to fix all of the problems at once can lead to false starts, resistance and confusion. Instead, identify two or three issues that will have the most impact on the business, and prioritize them during implementation.

- Evaluate the current IT infrastructure. Can the current environment support the ERP software? If not, have the IT team assess any needed upgrades, as well as their cost and how long they will take to implement.

- Set a budget, which includes the cost of purchasing the ERP software and the implementation process. Even a well-planned implementation can have surprises or unexpected delays. Build in contingency plans for any unforeseen costs and think ahead about continuous-improvement projects.

- Plan for integrations. Third-party applications, such as payroll, nesting or CAD software, will need to integrate seamlessly with the ERP software. Consider all of the touchpoints for the ERP software now and in the future to reduce the likelihood of multiple systems and redundant data entry.

- Make training a priority for all users. Training represents one of the most important parts of the implementation process, especially if employees have little or no experience with ERP. Training early and often will ensure that teams become comfortable with their new roles and responsibilities following go-live. Ensure that the ERP system offers multiple training channels―self-service, instructor-led, online, classroom and more. Going live with an ERP system represents the start of the race, not the end. Continuous improvement matters.

- Define roles and responsibilities. Before committing to an ERP vendor, clearly define the internal-team roles and responsibilities to ensure that the implementation remains a priority. Backfilling positions, relieving work and committing resources to the implementation will help to ensure commitment and success.

- Establish a timeline. Work with the ERP provider to establish a timeline with milestones for key deliverables. Additionally, setup a communication plan to ensure communication of critical information to both parties.

ERP implementation requires a team effort. A manufacturer can rely on the taskforce leader or a few senior individuals to steer the ship, but all employees are required to row. Ongoing communication and collaboration will lead to a more successful implementation.

ERP implementation requires a team effort. A manufacturer can rely on the taskforce leader or a few senior individuals to steer the ship, but all employees are required to row. Ongoing communication and collaboration will lead to a more successful implementation.

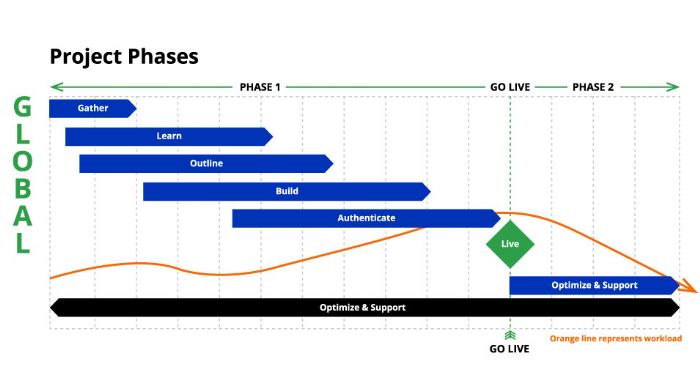

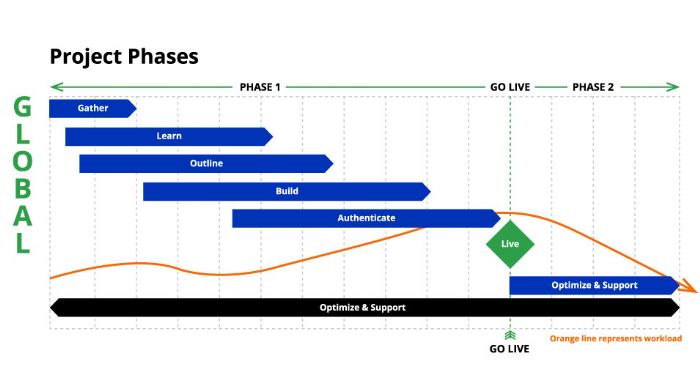

Six Stages to a Successful Implementation

With taskforce creation, ERP-system selection and a strategy in place, now’s the time to put careful planning into action. Follow the six-stage GLOBAL Implementation Method to a successful go-live.

1. Gather

This stage starts with gathering of information, planning and conducting the implementation kickoff. Key team activities include confirming the project scope and estimating a timeline to go live. Collect and distribute requested information, conduct business-process workshops for identified risk areas, and confirm the expected workload by resource.

Key deliverables include:

- Identify key team members for implementation

- Establish the scope and boundaries for the project

- Develop a baseline implementation plan

- Conduct the kickoff meeting.

2. Learn

This stage ensures that both the manufacturer and vendor teams understand the requirements needed to design and configure the system. This includes reviewing existing processes, documentation and requirements during planning sessions. Manufacturer-team members will:

- Attend workshops for gathering requirements and process mapping

- Identify data sources for data migration

- Participate in building the data-migration plan

- Review and approve business requirements

- Attend ERP training.

The vendor will:

- Identify business requirements

- Conduct onsite and virtual consulting visits

- Perform ERP installation

- Update baseline implementation planning and scheduling

- Identify interfaces or custom-programming requirements

- Hold ERP discovery sessions.

3. Outline

At this point, both teams work together to build future-state processes based on requirements. The manufacturer’s team will focus on the initial static-data load, review future-state process maps, and identify and inventory all required reports, forms and labels.

"To ensure success, take it slow and steady, and be thorough. An ERP implementation can be one of the best investments a manufacturer can make." - Chris Pinaire, Global Shop Solutions

The vendor will:

The vendor will:

- Discuss company setup and options

- Participate in walkthroughs of business scenarios

- Evaluate outbound/inbound forms and label requirements

- Discuss user groups and security

- Make updates to planning and scheduling (if needed).

4. Build

This step goes deeper into configuring the ERP system to meet user needs. The manufacturer’s team starts by cleaning, transforming and loading data, and attending system training. From there, focus on building forms, reports, labels, financial statements and financial reporting. This is followed by developing and testing use-cases and validating documented processes.

The vendor team:

- Assists with the building and loading of static and transactional databases

- Configures company options and group/user security

- Guides the setup/modification of forms, reports, labels and financial statements/reporting

- Builds integrations/customizations

- Trains the manufacturer’s team on documentation tools

- Guides the data migration.

5. Authenticate

In this step, both teams work together to test the system and its functionality. The vendor begins training users on the system and preparing for go-live. In addition to attending system training, the manufacturer’s team will update and finalize test scripts, perform readiness assessments, validate the data migrations, and perform other tasks needed to go live.

The vendor team:

- Confirms the reporting

- Audits cost flow from operations through financials

- Conducts train-the-trainer sessions

- Assists in end-user training

- Delivers integrations/custom programming

- Assists in final data migration

- Performs onsite training/preparation

- Prepares for go-live.

6. Live

This is the big day—turning off all legacy systems and processes, and launching the new ERP software. The last preparation steps include final data migration and final training with end users. Then flip the switch! The vendor team provides onsite support throughout the go-live process and assists with training and instruction as necessary.

After go-live, look to have the ERP vendor provide support for optimization and follow-up training. Going live is not the end, but rather the beginning. The ERP vendor should work with the manufacturer to identify additional improvements and transition for ongoing support, known as Phase II.

Phase II should include working with the vendor to identify further improvements, as well as ongoing support needs. Be sure to attend additional training offered by the vendor. Also, document lessons learned to avoid repeating mistakes as the implementation journey continues.

Prioritize the need for timely service and support. A variety of reliable and responsive support options will enhance any ERP implementation.

Be Thorough

To ensure success, take it slow and steady, and be thorough. An ERP implementation can be one of the best investments a manufacturer can make. Follow the steps outlined above and stick to the roadmap. Ask a lot of questions. Careful planning and thoughtful action will go a long way toward an implementation that finishes on time and within budget, while accomplishing the goals that a manufacturer hopes to achieve. MF

See also: Global Shop Solutions

Technologies: Management

Not so fast. Implementing ERP is not simple. This complex process requires a great deal of planning, teamwork, communication and collaboration. More importantly, begin planning long before the purchase of an ERP system to achieve the best results. Otherwise, the only thing to show from all of the sweat, blood and tears is an attempt to implement an ERP system that does not meet the needs.

Not so fast. Implementing ERP is not simple. This complex process requires a great deal of planning, teamwork, communication and collaboration. More importantly, begin planning long before the purchase of an ERP system to achieve the best results. Otherwise, the only thing to show from all of the sweat, blood and tears is an attempt to implement an ERP system that does not meet the needs.

ERP implementation requires a team effort. A manufacturer can rely on the taskforce leader or a few senior individuals to steer the ship, but all employees are required to row. Ongoing communication and collaboration will lead to a more successful implementation.

ERP implementation requires a team effort. A manufacturer can rely on the taskforce leader or a few senior individuals to steer the ship, but all employees are required to row. Ongoing communication and collaboration will lead to a more successful implementation. The vendor will:

The vendor will: