“The ERP landscape changed drastically in 2024. Transformative announcements in the world of AI left many businesses scrambling to evaluate their ERP strategy so they can remain relevant in the coming age of a new digital frontier. Fortunately, 2025 promises to deliver on the advancements made in 2024 ... but is your business ready?”

Adds Shawn Windle, founder and managing principal of ERP Advisors Group: “This time next year, we’re going to look back and say ‘Wow, it’s almost a completely different landscape.’”

If AI still seems out of reach or too futuristic, think again. Reading through “what’s new in ERP software” reports that follow this introduction, you’ll come to understand that AI already permeates most ERP packages. And its use will only grow, and quickly. Read on to get up to speed.

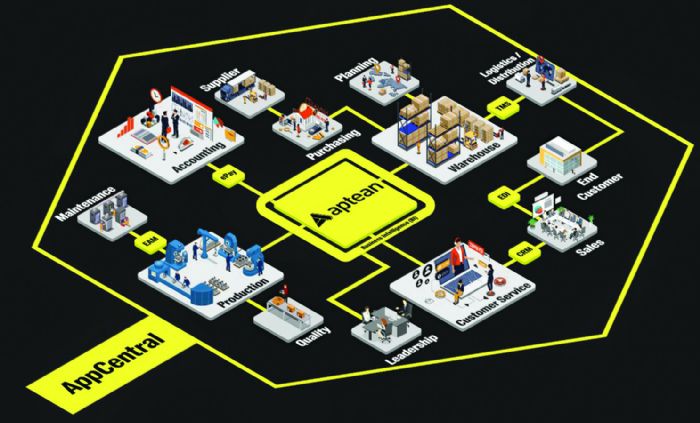

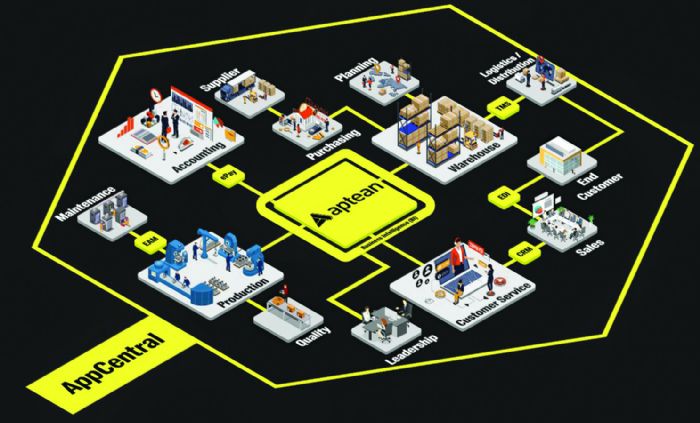

Aptean Releases AppCentral, an AI-Embedded Platform for Digitizing the Back Office

…from customer service to delivery. Aptean, Atlanta, GA, describes the new platform as “a broad portfolio of pre-integrated, AI-embedded, purpose-built solutions designed to digitize customers’ end-to-end operations.” App-Central integrates a suite of pre-connected, industry-specific applications into an AI-embedded platform, purpose-built to support end-to-end business efficiency. AI-optimized workflows, it says, will save businesses time and provide comprehensive visibility across the entire operation.

…from customer service to delivery. Aptean, Atlanta, GA, describes the new platform as “a broad portfolio of pre-integrated, AI-embedded, purpose-built solutions designed to digitize customers’ end-to-end operations.” App-Central integrates a suite of pre-connected, industry-specific applications into an AI-embedded platform, purpose-built to support end-to-end business efficiency. AI-optimized workflows, it says, will save businesses time and provide comprehensive visibility across the entire operation.

Aptean launched the new platform late in 2024 at its Unite customer conference, telling attendees that it was being trialed by the firm’s discrete-manufacturing customers.

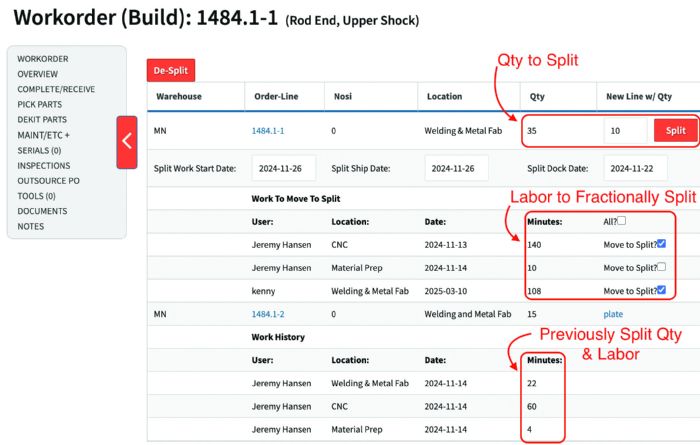

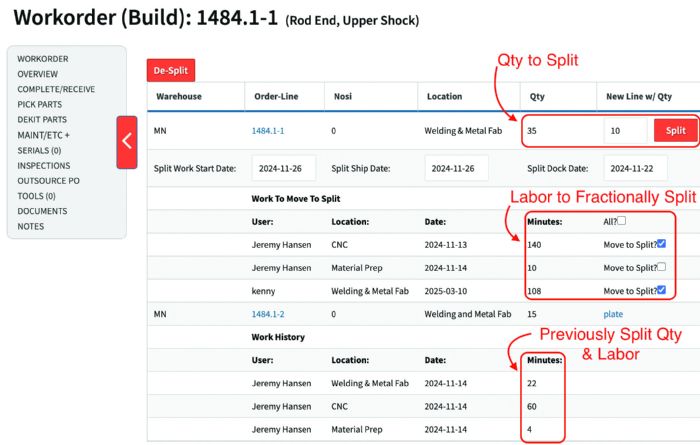

Cetec ERP Introduces Precision-Driven Features for Metal Fabricators and Machine Shops

Introduced in March 2025 by Cetec ERP, Austin, TX: a series of new features that directly address many of the day-to-day challenges faced by metal fabricators and machine shops. Among them:

Introduced in March 2025 by Cetec ERP, Austin, TX: a series of new features that directly address many of the day-to-day challenges faced by metal fabricators and machine shops. Among them:

- Drag-and-drop scheduling, a tool that allows users to drag and drop orders to schedule forward or backward on the Gantt Chart. This allows for visualizing “what-if” scenarios and replicates kanban scheduling.

- Enhanced batching functionality, promising to simplify the management of multiple orders scheduled and running in a batch, improving material allocation and reducing inventory excess through better job-status updates and labor tracking.

- Outsource PO and PQuote linking, a unique feature that streamlines the creation and integration of outsource POs into production plans, enhancing cost control and production timelines.

DelmiaWorks’ Release 2025 Provides Enhanced BOM Management, Traceability and More

With the new year came Release 2025 from DelmiaWorks, with new features including enhanced bill-of-materials (BOM) management, traceability, quality controls and functionality. For BOM management, the system’s tool called 3DExperienceBridge streamlines data governance with a web-based data-integration application that connects the platform with the DelmiaWorks manufacturing ERP system to enforce a single source of truth across the product lifecycle, from a SolidWorks or other engineering-data model to engineering BOM to manufacturing BOM. The tool enables collaborative cloud-based product-lifecycle management and unified management and control of multiple manufacturing facilities’ data within a single platform.

Release 2025 also features enhanced real-time process monitoring via machine-to-machine communication using MQTT technology. The MQTT device map allows equipment to be connected to the ERP using the MQTT IIoT communications protocol.

Other enhancements include:

- An improved web-based track-and-trace application that simplifies access to critical information from anywhere.

- eSignature and training certification, providing instant access to pending training sessions and certifications.

ECI Debuts New MES & APS Integrated Solutions

ECI Software Solutions recently launched two new integrated solutions for its ERP products—ECI Manufacturing Execution System (MES) and ECI Advanced Planning & Scheduling (APS). ECI MES enables metal forming shops to digitize their shop floor with support for more than 140 PLC/IO devices, providing real-time visibility into machine performance. With built-in analytics for overall line efficiency, overall equipment effectiveness and total effective equipment performance, manufacturers can identify inefficiencies and optimize production.

Smarter scheduling tools account for machine, tooling and personnel constraints, while integrated alerts, messaging and document management help streamline workflows, reduce downtime and improve on-time delivery. ECI APS extends MES capabilities by providing flexible scheduling for short- and long-term production needs. It accounts for multiple resource constraints, integrates live progress updates from equipment and adapts to real-time shop-floor changes.

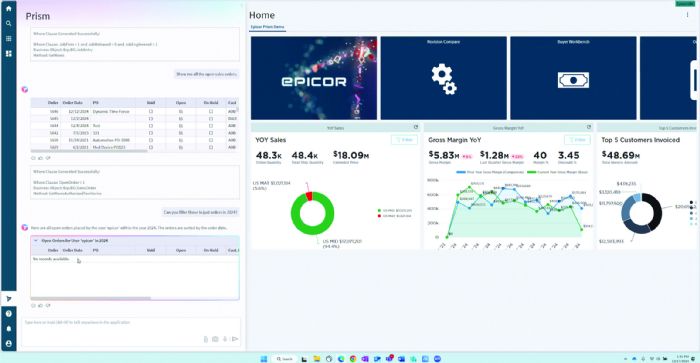

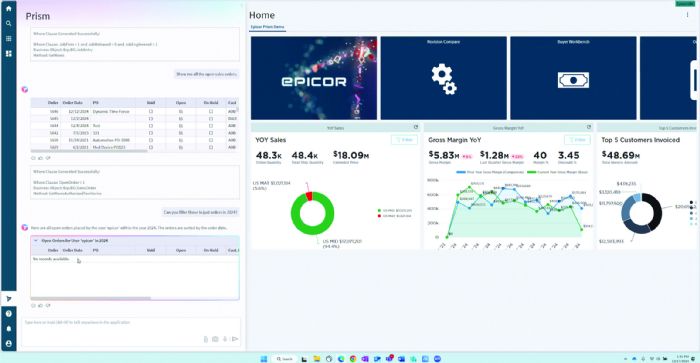

Epicor Prism Vertical AI Agents Help Frontline Workers Unlock the Power of Data

January marked the introduction of Epicor Prism, a network of vertical AI agents built specifically to simplify how workers access answers and recommendations to complex business needs, and enable organizations to take quick action. Epicor Prism is initially available for integration with Epicor Kinetic.

January marked the introduction of Epicor Prism, a network of vertical AI agents built specifically to simplify how workers access answers and recommendations to complex business needs, and enable organizations to take quick action. Epicor Prism is initially available for integration with Epicor Kinetic.

“Epicor Prism helps users unlock the power of their data to make informed decisions and take action in ways that were previously unimaginable,” says Arturo Buzzalino, Epicor chief innovation officer. “Through simple, natural-language queries, Prism’s vertical AI agents quickly source and provide the best answer or recommendation to a user’s need.”

An example of Epicor Prism’s application: Employees can use conversational ERP to access production, purchasing and logistics insights without the need to know where files are located. Epicor Prism also can automate supplier communications to speed purchasing, enabling users to automatically send RFQs to their supplier network, and parse and translate quotes to determine the best price and fastest delivery.

Global Shop Solutions Adds Dashboard Designer Feature

MetalForming magazine and the Precision Metalforming Association are excited to host an informative forum on Industry 4.0 applications for metal formers and fabricators, and a tour of some of the industry’s leading ERP software systems. The Industry 4.0 Forum and ERP Shootout takes place July 16-17 in Northbrook, IL. For details and to register. MetalForming magazine and the Precision Metalforming Association are excited to host an informative forum on Industry 4.0 applications for metal formers and fabricators, and a tour of some of the industry’s leading ERP software systems. The Industry 4.0 Forum and ERP Shootout takes place July 16-17 in Northbrook, IL. For details and to register.

|

As manufacturing complexity increases, so does the need for metal formers and fabricators to customize the way in which they access and visualize accessing operational and financial data. To that end, Global Shop Solutions has introduced a Dashboard Designer feature that simplifies a user’s ability to design, customize, track and display data in formats that meet their unique business needs.

“Dashboard Designer is a no-code data-analysis tool manufacturers can use across their organization,” says Dusty Alexander, president and CEO of Global Shop Solutions. “Manufacturers can tailor dashboards to their own specifications by dragging and dropping features directly onto the screen.”

Basic templates come standard with the ERP and can be edited according to user preferences. The most popular dashboards include sales analysis, employee productivity, real-time workcenter dispatches and work order estimate versus actual.

One of the newest Dashboard Designer features allows manufacturers to display shop floor metrics on interactive TV screens located on the shop floor. Reportedly five times faster than running a report, the interactive TV screens have proved so efficient that the Dashboard Designer team created a “sister” Report Designer to generate faster, more customized reports.

Infor’s CloudSuite Update Includes GenAI Assistant

|

The MetalForming website recently published a handful of articles discussing the growing importance of advanced IT tools, including AI, for metal formers and fabricators. Please visit the site to read:

Authored by Matthew Heerey, president, manufacturing division, ECI Software Solutions, this article discusses why metal formers that prioritize investments in innovative technology will capture momentum and fortify resilience during the second half of 2025. “Manufacturers can sustain growth by embracing decentralized systems and integrating AI-powered smart factories,” he writes. “These approaches can streamline processes and boost overall productivity.”

Authored by Jake Rohrer, a manufacturing digital strategist at Wipfli, this article discusses the use of generative-AI tools for strategic-plan development, branding and marketing, manufacturing-process improvement, employee training and upskilling, and much more.

MetalForming interviewed DelmiaWorks’ chief marketing officer Steve Bieszczat to discuss an array of challenges, and opportunities, facing metal forming companies. Among them: the trending onshoring movement; tariffs; investments in automation to increase capacity utilization; the analytics required for managing production, inventory, finance and other manufacturing operations, and the role of AI; and new MES software features to complement new “smart” machines.

|

Infor, during its 2024 Velocity Summit last October, announced significant platform technology updates to its industry-specific CloudSuite portfolio. New innovations include a GenAI Assistant, process-mining capabilities, and ESG strategy management.

Infor GenAI Assistant, designed to enhance user experience, is a conversational tool that provides a dynamic, intuitive and actionable approach to interacting with industry-centric data, addressing time-consuming tasks such as managing manufacturing projects, analyzing requisitions and tracking products.

Infor Process Mining provides users with streamlined data definition, simplified export-import capabilities, efficient data loading, accelerated insights retrieval and comprehensive insights analysis. One use of the technology, Steve Turner, director of information systems for Oberg Industries, says: “This transformative tool provides visibility into business process events within our daily order-to-cash operations, highlighting areas for improvement and actionable opportunities. We anticipate that by addressing these process inefficiencies and bottlenecks we will be able to increase our business throughput with existing resources over time.”

Plex Adds Connected Worker Capabilities to its MES

Late in 2024, Plex, by Rockwell Automation launched its connected-worker solution, designed to help users enhance productivity, quality and safety on the shop floor, and support efforts to retain, attract and reskill workers. Connected frontline workforce (CFW) applications provide real-time guidance, visual aids and multimedia content, enhancing comprehension and reducing errors on the job. By streamlining the number of applications manufacturers need, the solution also reduces total cost of ownership, time to value and cybersecurity risk, say company officials.

“CFW applications are a strategic imperative to address critical challenges in safety, quality and productivity,” says Allison Kuhn, an analyst at LNS Research. “Manufacturing leaders deploy these applications to bridge skills gaps, improve employee retention and enhance the overall employee experience through better user interfaces, interactive training and real-time insights.”

The new capabilities, directly embedded within Plex’s MES, provide a single source for optimizing productivity without the need for multiple subscriptions. Among these new features: guided and interactive work instructions, providing step-by-step task guidance for people, machines, and devices. Advanced capabilities, the company reports, will include chat features in partnership with Microsoft Teams; activity management of people and machines; and key measurable capabilities.

Rootstock Software Launches Spring ‘25 Release

In April, Rootstock Software announced its Spring ’25 release that includes a sweeping user-experience (UX) uplift and a host of financial and AI-driven enhancements. The updated experience will be introduced in phases throughout the year and across various modules, focused on four key areas: clarity, efficiency, consistency and usability. These enhancements promise to enable faster data entry, minimize clicks and screen transitions, and introduce smart layouts that adapt to the task at hand.

Various redesigned master pages allow users to view everything from contacts and orders to pricing, credits, and invoices—all in one consolidated page. And, Rootstock now provides real-time inventory visibility within field-service workflows, enabling technicians and dispatch teams to access current information.

Rootstock also continues to leverage AI to increase automation and efficiency. In its new release, Rootstock’s AI engine (called AIRS) is embedded into quick-entry and quick-order screens. By analyzing customer history and common buying patterns, AIRS intelligently recommends products to enable sales teams to anticipate customer needs and quickly and accurately build orders.

An App for Stampers that Covers Shop-Floor and Business-Enterprise Functionality

ShopEdge Software introduced its Unified Application to its application suite during FABTECH 2024 in Orlando. Bringing together its shop-floor and business-enterprise functionality into a single application, developed using Microsoft’s open-application framework Blazor, ShopEdge Unified Application can run in any web browser or as a native client application on most devices, providing fast, almost native performance using a desktop or mobile form factor. And, because Blazor is a modern front-end framework based on web standards, ShopEdge notes that it can develop features quicker in an application with an enhanced user experience.

ShopEdge Software introduced its Unified Application to its application suite during FABTECH 2024 in Orlando. Bringing together its shop-floor and business-enterprise functionality into a single application, developed using Microsoft’s open-application framework Blazor, ShopEdge Unified Application can run in any web browser or as a native client application on most devices, providing fast, almost native performance using a desktop or mobile form factor. And, because Blazor is a modern front-end framework based on web standards, ShopEdge notes that it can develop features quicker in an application with an enhanced user experience.

The Unified feature-rich, robust application that covers all aspects of metal stamping, from capturing shop-floor data to analyzing business metrics. The app is accessible on Android, iOS, Windows and a web browser.

QAD’s Adaptive ERP—Enhanced Scheduling, and AI to Help Navigate Tariffs

Late in 2024, QAD announced new scheduling and AI capabilities in its Fall product launch, to help manufacturers boost productivity. QAD Advanced Scheduling promises to help manufacturers optimize production decisions, the company says, by determining the best sequence for manufacturing a product on each line. It aligns with an organization’s cost and servicing goals and minimizes changeovers, while optimizing inventory management.

QAD also launched a generative AI assistant for product classification, within its Global Trade and Transportation Execution solution called Champion. Champion uses models to answer business needs and give tangible results. It also assists organizations in ensuring accurate product classifications for the import and export market while determining tariffs, qualifying for trade agreements or adhering to government regulations.

Learn more from this on-demand webinar, Key Factors for Choosing the RIght Manufacuring ERP. MF

See also: Global Shop Solutions, Epicor Software Corp., Aptean, Plex, A Rockwell Automation Company, ShopEdge Software Inc.

Technologies: Management

This uncertainty comes at a time when, thankfully, new tools have come online to help. Notably, the quick ascent of artificial intelligence (AI) into the manufacturing culture. Per a recently published manufacturing trends report from ERP company ECI Software Solutions:

This uncertainty comes at a time when, thankfully, new tools have come online to help. Notably, the quick ascent of artificial intelligence (AI) into the manufacturing culture. Per a recently published manufacturing trends report from ERP company ECI Software Solutions:

…from customer service to delivery.

…from customer service to delivery.  Introduced in March 2025 by

Introduced in March 2025 by  January marked the introduction of

January marked the introduction of  MetalForming magazine and the Precision Metalforming Association are excited to host an informative forum on Industry 4.0 applications for metal formers and fabricators, and a tour of some of the industry’s leading ERP software systems. The Industry 4.0 Forum and ERP Shootout takes place July 16-17 in Northbrook, IL.

MetalForming magazine and the Precision Metalforming Association are excited to host an informative forum on Industry 4.0 applications for metal formers and fabricators, and a tour of some of the industry’s leading ERP software systems. The Industry 4.0 Forum and ERP Shootout takes place July 16-17 in Northbrook, IL.