“We may want four or five lubrication lines on one tool, and three or four on the next,” Pikunas says, noting that a combination of flexible and hard-piped lines are utilized depending on the application. “The lines are set correctly at the beginning of the job and locked into a specific spot on the tool, and are robust enough so that press movement or something or someone bumping into them won’t move them around. That flexibility and robustness helps us reduce setup time.”

Better Lube Control,Less Housekeeping

|

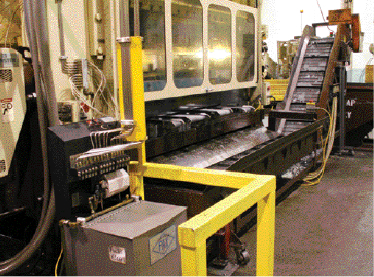

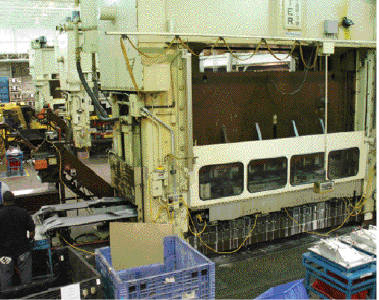

| This press at contract stamper Schaller Corp. employs a lubricant delivery system (foreground) that sprays directly on the strip in various locations in a progressive die. Previously, the company flooded dies with lubricant, a costly and messy process. |

Of course, with spraying, customers receive parts with less lubricant on them —in most cases just a fine film.

“Customers specify the amount of lube that can be on the part, and if we didn’t put enough lube on, the part would rust,” says Pikunas. “Too much lube causes issues with the customer related to handling, welding or other secondary operations. So we did have instances where the customer would request that we wash or wipe the parts prior to delivery.”

At Schaller, an initiative has given the same importance to production, quality and housekeeping. In addressing housekeeping, the company seeks to eliminate clutter on the floor and keep only absolutely necessary equipment at the stations. With lubrication, housekeeping means keeping it contained as best as possible. In flooding dies, employees constantly spent time mopping lubricant off of the shop floor.

“This results in operators unable to spend time checking parts or returning a press to production,” notes Pikunas. “With spraying, we dial in exactly how much we want to spray within the 360-deg. pitch of the stroke of the die. We control the amount of lube used on the strip and the die, so lube does not hit the floor. The spray operation results in virtually no housekeeping issues.

“We’re trying to create an atmosphere in the company that allows employees to focus on the production job at hand,” he continues. “They can monitor what’s in the press and what part is exiting the die, and determining if that part is a quality part. At the end of the day, our operators want to make parts, not mop floors. The company reports that it saves tens of thousands of dollars annually on lubrication costs due to the switch from flooding to direct-spray application, and has realized its target of an 18-month-or-less return on investment.

Doors, Filtering System Control Mist

|

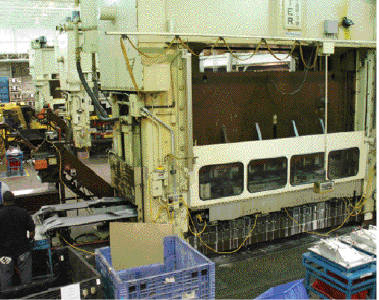

| This Minster 1600-ton unit, reportedly the world’s largest two-point eccentric-shaft press, employs die doors to assist in lubrication containment and protect workers should a malfunction cause parts or scrap to fly out of the die. |

Assisting in lube containment are Pax die doors integrated into press shields as well as a system to handle lubricant mist. Because of the tremendous amount of heat generated during stamping, steam is produced when the water-soluble lubricant hits the hot progressive tooling. The steam acts as a lubricant carrier, necessitating a method to contain it, especially in situations where a component such as a conveyor exiting the press results in an open press window. To combat that, Schaller has incorporated a filtering exhaust system, also from Pax Products.

“We use it to capture any particles getting into the air,” says Pikunas. “We can do that with assistance from the die doors that help create a vacuum exhaust. As a result, we have no air-quality issues.”

Every press at Schaller incorporates die doors. The company had experimented with many different doors—homemade and purchased—trying to find doors best able to contain lubrication and protect employees. The doors from Pax have done that, says Pikunas, and their light weight has provided ease of use.

“Unlike in the past, we no longer have health and safety issues due to operators trying to lift up the doors,” he says. “Also, the doors can be locked in a number of positions so that a door can’t swing down and injure an employee.”In addition, the doors provide safer press operation.

|

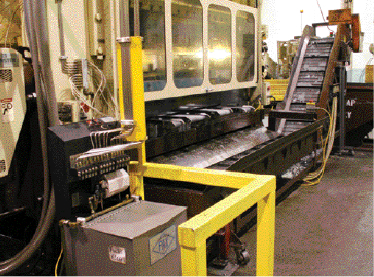

| Schaller Corp. switched to low-profile conveyors such as these, bringing better control of part and scrap removal. An added benefit: The conveyors last much longer than expected in the hostile stamping environment. Note the lubricant runoff below the conveyors. Schaller captures and reclaims its lubricant, bringing a host of cost and safety benefits. |

“A limit switch must be engaged, so the door must be in a closed and set position for the press to run,” says Pikunas. “That’s a big concern to us—in the past, we’ve had an instance where a miss-hit occurred in a press and a detail flew out of the die and struck the operator.”

Additionally, the company uses Pax spray cabinets to apply lubricant to the material before it enters the die. With the cabinet—an enclosure mounting to the feeder and extending through the press window on the entry side—built-in spray nozzles coat material top and bottom, before the material enters the die. Any lubricant captured in the enclosure can be returned to the lube system or to a pit to facilitate recycling.

“By placing a light coat on the coil, we are less likely to have issues related to strip not being lubricated as it traverses the die,” says Pikunas.

Sensored Conveyors Reduce Clogging

Another press improvement at Schaller revolves around part and scrap removal.

“In years past, we were not able to integrate conveyor operations into the press logic system,” Pikunas recalls, hampering the use of sensors in areas such as under the die where scrap would exit onto conveyor systems. “Scrap could pile up, get up into the tool and blow out our die.”

Low-profile conveyors, again from Pax, helped provide the connectivity Schaller needed.

“Sensored properly, when the conveyor stops the press will stop,” Pikunas says. “When we sensor conveyor operations, we know that the belts are moving and that scrap is exiting. With our new setup, the press stops in a certain amount of time if the conveyor belt stops moving. Then we can examine the tool and find out why.”

The conveyors also have exhibited long life in the harsh stamping environment, according to Pikunas.

“The Pax belt has provided us at least one-and-one-half times the life of a normal belt,” he says, noting that typical conveyor life is five years, and some of the Pax conveyors are going on eight years. “And whether we use the conveyors in flood or spray operations, they can withstand the excessive amount of fluid because the units are well sealed, including the motor and related components.”

Preventive maintenance (PM) at Schaller helps add to conveyor life.

“We have a program where, once the conveyor is taken out of operation, we clean it and provide standard PM,” Pikunas says. “We wash it and check the belt—either retensioning or replacing it based on the amount of wear. Belt replacement only takes about 10 min.” MF

Information for this article provided by Pax Products, Inc., Celina, OH. Tel. 800/733-6930; http://www.paxproducts.com/.

See also: Nidec Press & Automation, Pax Products, Inc.

Technologies: Lubrication, Pressroom Automation, Stamping Presses

Webinar

Webinar