OEM Realizes 60% Reduction in Stamping-Lube Use

February 6, 2025Comments

Recognizing that “more lubricant isn’t always better,” Armstrong International’s team of process engineers addressed the over-application and wasteful use of stamping lubricant at its captive pressroom. Results: 60% reduction in lube use, 30% increase in draw-die life and improved operator safety.

Armstrong International, Three Rivers, MI., manufactures thermal utility-system components. The fifth-generation, family-owned business, founded in 1900, relies on its process-engineering department to continuously improve efficiency and productivity. That mission recently impacted the firm’s inhouse stamping department when engineers sought to better-control its stamping-fluid use, to reduce waste and improve operator safety. For help, it turned to metal working fluid and equipment distributor Impact Fluids, Grandville, MI, and one of its equipment suppliers—Unist Inc.

“The main challenge we faced,” shares Armstrong manufacturing engineer Mark Sikorski, “involved stamping deep-drawn, primarily Type 304 stainless-steel cups for our line of steam traps. This is a difficult application for fluids, and the philosophy often was ‘more lubricant is better,’ but that had to change.”

“The main challenge we faced,” shares Armstrong manufacturing engineer Mark Sikorski, “involved stamping deep-drawn, primarily Type 304 stainless-steel cups for our line of steam traps. This is a difficult application for fluids, and the philosophy often was ‘more lubricant is better,’ but that had to change.”

Armstrong remains committed to performing the critical stamping processes inhouse for manufacturing its steam traps, stamping all of the internal and external components using a variety of presses, including new servomechanical models added in the last few years. For the deep-drawn cups, the press of choice is a recently refurbished 250-ton Nidec Minster mechanical press. The firm, which also operates out of Europe, China, Canada and Mexico, produces hundreds of thousands of traps annually; the Three Rivers facility supplies stampings to all of those locations.

Armstrong remains committed to performing the critical stamping processes inhouse for manufacturing its steam traps, stamping all of the internal and external components using a variety of presses, including new servomechanical models added in the last few years. For the deep-drawn cups, the press of choice is a recently refurbished 250-ton Nidec Minster mechanical press. The firm, which also operates out of Europe, China, Canada and Mexico, produces hundreds of thousands of traps annually; the Three Rivers facility supplies stampings to all of those locations.

Deep Drawing Turns up the Heat

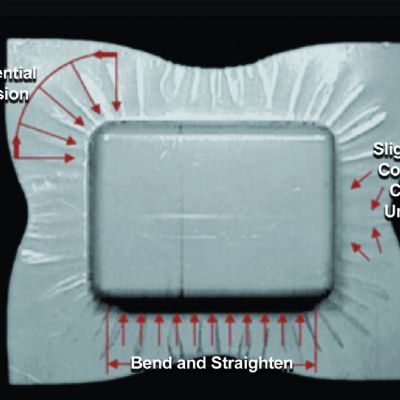

Cups are drawn of material to 0.110 in. thick, with a maximum draw depth of 3.875 in. and cup diameter to 2.5 in. The work accounts for some 50% of the press’s production capacity.

“The multistep deep draw generates a lot of heat,” says Sikorski. “Prior to reaching out to Impact Fluids, we were using an old roller-application system to apply oil to the material, and we struggled to get an even coating. And, downstream in the process along the 72-in.-long progressive die, the spray nozzles over-applied lubricant and created a mess. The process, running at 22-25 strokes/min., was quite challenging to anyone near the press.”

“The multistep deep draw generates a lot of heat,” says Sikorski. “Prior to reaching out to Impact Fluids, we were using an old roller-application system to apply oil to the material, and we struggled to get an even coating. And, downstream in the process along the 72-in.-long progressive die, the spray nozzles over-applied lubricant and created a mess. The process, running at 22-25 strokes/min., was quite challenging to anyone near the press.”

Step one for the team at Impact Fluids: “We used our fluids-lifecycle-analysis process and looked specifically at the application system,” says company president John Hoff. “Its existing system was a poorly designed roller system that flooded the stock and then tried to wipe it off before the material entered the press. There was no consistency, so over-oiling was the operative choice.”

The solution: a new oil-application system that includes a Unist Uni-Roller stock lubricator with 12-in. rollers, and SmartFlow controller, supplemented with four downstream Unist air-assisted low-volume spray nozzles.

The solution: a new oil-application system that includes a Unist Uni-Roller stock lubricator with 12-in. rollers, and SmartFlow controller, supplemented with four downstream Unist air-assisted low-volume spray nozzles.