Spin-Pull Technology Enables Automated Clinch-Nut Installation on Closed Profiles

January 31, 2022Comments

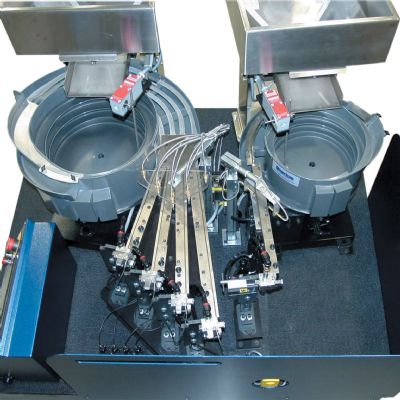

Spin-pull technology from MDS | Autoriv,

reportedly in use at several OEMs, enables automated installation of clinch and

rivet nuts in one-sided sheet metal-joining positions, such as with closed

profiles. In addition, metal formers can use the process with thicker metal

sheets by combining the clinch nut with a washer or spacer, reportedly a superior

process to using blind rivet nuts, say company officials, who note that joints

created with the spin-pull process can withstand higher forces from any load direction.

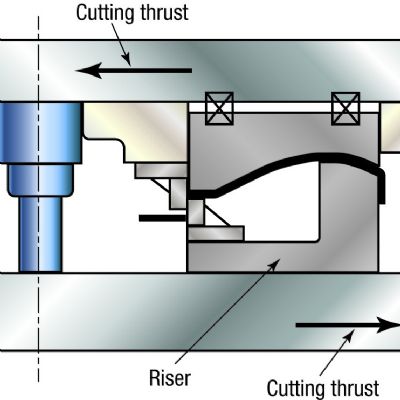

The technology offers a new approach for handling closed profiles without

opening them and affecting the stability of the workpiece.

Spin-pull technology from MDS | Autoriv,

reportedly in use at several OEMs, enables automated installation of clinch and

rivet nuts in one-sided sheet metal-joining positions, such as with closed

profiles. In addition, metal formers can use the process with thicker metal

sheets by combining the clinch nut with a washer or spacer, reportedly a superior

process to using blind rivet nuts, say company officials, who note that joints

created with the spin-pull process can withstand higher forces from any load direction.

The technology offers a new approach for handling closed profiles without

opening them and affecting the stability of the workpiece.

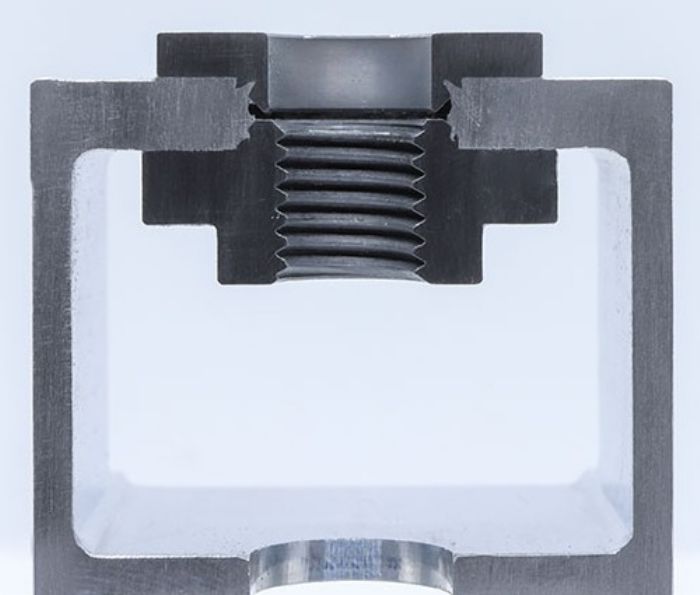

With blind rivet nuts, the joint only hangs on the rivet bulge and the counter sheet screws against the head of the nut; there is no preload between the connected sheets and the connection cannot withstand high forces. By contrast, the larger diameter and height of a clinch or rivet nut exceeds the size of the bulge a blind rivet nut, allowing the fasteners to withstand higher forces from any load direction, even in applications with high side loads. A preload builds up between the connected sheets to ensure high-strength structural connections.

The four-step spin-pull process:

- A sliding unit carries the clinch nut to the pilot hole inside the profile, positioning the nut under the pilot hole.

- The assembly unit moves into the pilot hole and spins into the nut beneath. As an option, the also can carry a spacer.

- The unit applies an axial pulling to the joint to create a form-fit connection between nut, metal sheet and spacer.

- The pulling mandrel spins out.

See also: AUTORIV

Technologies: In-Die Operations, Welding and Joining

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. In-Die Operations

In-Die OperationsManaging Horizontal Forces in Stamping Dies—Part 1

Peter Ulintz Thursday, April 30, 2020

In-Die Operations

In-Die OperationsIn Die Fastening, Part One—The Whys and Hows

Andrew Cooke Thursday, January 31, 2019