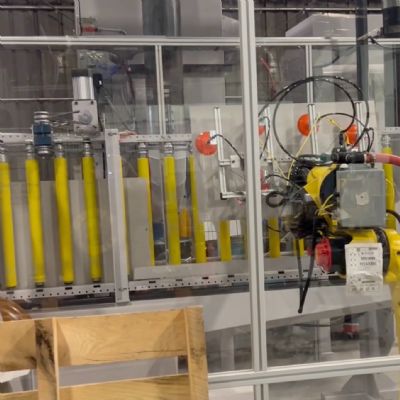

Descaling Batch-Operation Machine Removes Contaminants from Coil Wire

April 1, 2010Comments Wheelabrator Group, Burlington, Ontario, Canada, introduces a Coilblast descaling machine designed for

|

Ezefit wheels are simple to assemble and take apart, says the manufacturer, allowing for 50-percent reduction in change time compared to other wheel systems.

The machines boast double- or single-swing door configurations and a fold-in oscillating mandrel—a space-saving feature that simplifies material handling. Choose from 10-, 13- or 15-ft. mandrel length. The bulk coil shot-blast descaling system avoids wire uncoiling and minimizes processing times.

Wheelabrator Group: 800/845-8505; www.wheelabratorgroup.com

See also: Wheelabrator Group, Inc.

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

FinishingAutomated Machinery for Grinding, Deburring and Finishing

Thursday, August 1, 2024

Lubrication

LubricationDaubert Cromwell Appoints Rodrigo Martinez Mexico Country Le...

Monday, March 18, 2024