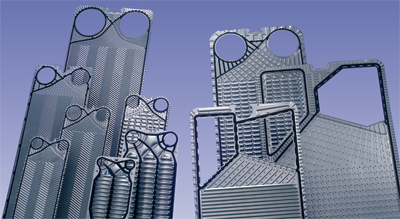

Multi-Cylinder Press Enhances Heat-Exchanger Production

January 1, 2009 A new forming line employs hydraulic-press technology containing many small cylinders instead of one large one. The result: faster cycle time, increased output and precise forming.

The use of several small cylinders in this unique hydraulic-press design allows more precise control of material flow, a must in the exacting work of producing heat-exchanger plates.

|

| A new forming line at the York, PA, facility of GEA PHE Systems employs hydraulic-press technology containing many small cylinders rather than one large one, to achieve full force. The small cylinders fill faster and require substantially less compressible oil compared to a press with a large cylinder and longer stroke, resulting in much faster cycle time and higher output. |

As a leading U.S. manufacturer of gasketed, fully welded and brazed-plate heat exchangers, GEA PHE Systems NA, Inc.’s products find use in residential, commercial and industrial applications in sectors as diverse as chemical, food, sugar, marine, power, HVAC, renewable energy and refrigeration. Part of the GEA Process Equipment Division of the international GEA Group, the company maintains production facilities in Germany, Sweden, Canada and India as well as the United States, and distributes the heat exchangers worldwide.

To gain productivity and maintain precise material control throughout the forming process to produce the heat exchangers, the company has employed a new short-stroke multi-cylinder hydraulic press from Schuler Inc., Canton, MI.

Needed Press to Provide Precise Forming

Compact, efficient and cost-effective heat-exchanger designs at GEA PHE Systems depend on precise engineering and manufacturing, with tolerances as tight as 0.002 in. for channels and bevels.

In planning its new production facility in York, PA, the company set out to design-in extremely high precision and productivity. Jean-Pierre Castenetto, GEA Ecoflex head of production and logistics, developed an ambitious wish list for the new production line:

• Encounter very low bolster and table deflection;

• Gain the ability to make a variety of plate sizes in several material types requiring a high press force;

• Develop an automated system requiring a single operator.

“We also needed high levels of flexibility and productivity, including a faster process and the ability to minimize downtime by changing dies quickly to make different-sized plates,” says Castenetto. “Plus, a high level of automation was important for meeting our productivity goals.”

Fully Automated and Flexible

Schuler responded with a concept for a custom hydraulic-press system featuring a short-stroke, multi-cylinder design. This approach allows precise material flow with high final quality—no wrinkles or defects, according to Schuler officials.

|

| The new hydraulic-press system at GEA PHE Systems includes a decoiling line with shear, automatic feeding with a single-rail shuttle into the embossing press and a die-change cart able to simultaneously handle three dies. A single-rail shuttle removes formed plate from the embossing press and transports it to a blanking press. The exit side of the blanking press features gantry-type automation to remove and stack the plates. |

The system—Schuler engineered, manufactured, delivered and installed it as a turnkey project—includes a decoiling line with a shear, automatic feeding with a single-rail shuttle into the embossing press and a die-change cart able to simultaneously handle three dies, allowing complete die change in less than 30 min. It also includes a single-rail shuttle that removes formed plate from the embossing press and transports it to a blanking press. The exit side of the blanking press features gantry-type automation to remove and stack the plates.

The press employs many small cylinders rather than one large one, to achieve full force. The small cylinders fill faster and require substantially less compressible oil compared to a press with a large cylinder and longer stroke, resulting in much faster cycle time and higher output. Repair time and expense also are greatly reduced compared to what a large-cylinder design would require, say Schuler officials.

In addition, the multi-cylinder design allows GEA PHE Systems to make heat-exchanger plates in a variety of sizes, providing the flexibility to meet changing production needs and customer demand. The company now produces as many as four parts/min., with one operator handling the entire process. For the 28,000 tons of force provided by the press, the output rate is believed to be one of the best in this industry, add Schuler officials.

John Garrity, production manager for gasketed-plate heat exchangers at GEA PHE Systems, likes the press’ versatility and high level of automation.

“It provides us with the flexibility to quickly change jobs and make a variety of plates,” he says. “Plus, we can provide blanks to other processes within our company, and we can do it all with just one operator. That’s a tremendous productivity advantage.”

Numerous Applications for Multi-Cylinder Technology

Though designed specifically to meet the needs of GEA PHE Systems, Schuler sees numerous other opportunities for its multi-cylinder technology.