Finishing Steel Weld Seams

January 30, 2020Comments

Approaches and abrasive selections differ when finishing carbon steel or stainless steel welds. Here's how to navigate the process for each material.

|

| Photos courtesy of Norton | Saint-Gobain Abrasives |

Prior to welding, particularly when working with carbon steel, clean the workpiece to remove any mill scale formed from the hot rolling manufacturing process. Mill scale can interfere with weld quality.

Finishing Carbon Versus Stainless Steel

The decision over finishing requirements links strongly to the application of the finished piece and the base material itself. Note that not all welds require seam removal in order to achieve a functional piece. This is especially true for carbon steel—it’s almost always painted, or the seam otherwise may not be visible. Examples include undersea piping or when the metal serves a structural function and hides behind a panel. Note, too, that unfinished welds are inherently stronger than finished welds due to the material removal involved in grinding them down.

In finishing carbon steel, a fairly simple process, the majority of cases involve preparing the steel only where paint will be applied. A rough and well-scratched surface helps the paint adhere better to the metal than a highly finished surface. In fact, for powder coating applications, a coarse-grained two-step weld removal probably is sufficient.

Stainless steel, intrinsically stronger than carbon steel, generally is of much thinner gauge. This feature has implications for grinding, which will be discussed later. The weld finish for stainless steel also depends on the application. For instance, a highly refined finish may be used for aesthetic purposes, whereas an elevator wall panel or hand rail requires a functional No.4 finish to disguise the visibility of fingerprints and scratches.

|

| Flap discs typically get the nod for stainless steel finishing. |

Finishers working with both materials should keep them in separate areas of the shop―as well as any abrasives used―to avoid cross-contamination, especially when transitioning from carbon to stainless steel finishing.

Initial Weld Grinding

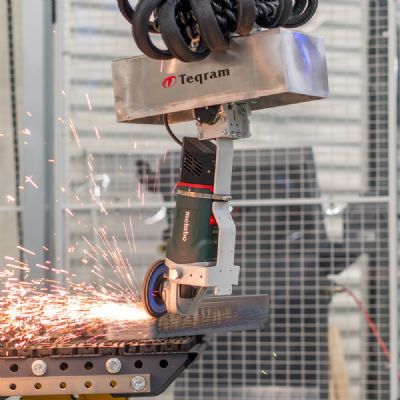

Weld finishing for both carbon and stainless steel involves the same initial stage: removal of excess stock from the weld itself, with the aim to grind the joint down to a level and continuous surface with the rest of the parent metal. To achieve this initial stock removal, should the surface finish be deemed nonessential, the metal worker might choose to use a simple grinding wheel with an angle grinder.