Upgraded High-Performance Cutting, Grinding and Combination Wheels

August 28, 2024Comments

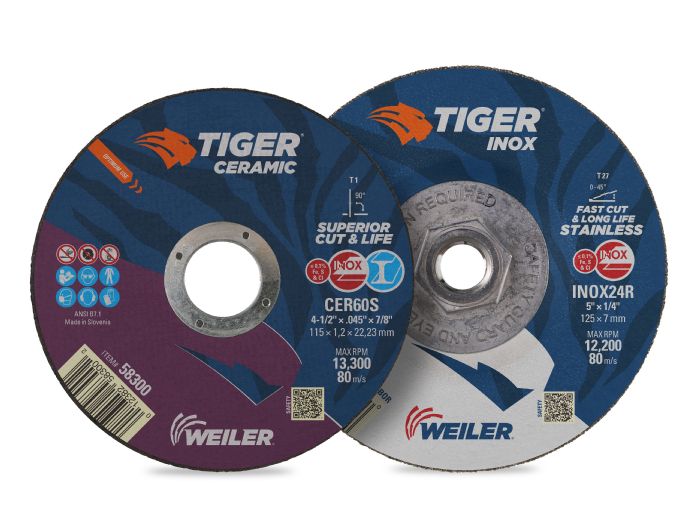

Designed to address the challenges of demanding metal-fabrication applications, new Tiger Ceramic 2.0 and Tiger Inox 2.0 wheels from Weiler Abrasives offer a superior combination of life and cut rate for maximum productivity, according to company officials.

Designed to address the challenges of demanding metal-fabrication applications, new Tiger Ceramic 2.0 and Tiger Inox 2.0 wheels from Weiler Abrasives offer a superior combination of life and cut rate for maximum productivity, according to company officials.

Tiger Ceramic 2.0 wheels (see video) offer a unique design that leverages innovative ceramic grain-technology that reportedly cuts cool and removes material easily while providing exceptional control for an improved operator experience. Wheel life has been improved by increasing grain retention and ensuring precise product wear. Extensive testing shows that the ceramic wheels deliver long product life with no reduction in cut speed, according to company officials, who claim that the wheels offering two times the life compared to the latest ceramic wheels on the market, with the grinding/combo wheels providing as much as 30% more product life.

Inox 2.0 wheels are designed for high performance when cutting and grinding high-value stainless-steel parts. Premium aluminum oxide grains reportedly provide a smooth cut rate and consistent performance. And, both Tiger Ceramic and Tiger Inox wheels are contaminant-free, making them safe to use on high-value stainless-steel parts.

The Tiger 2.0 upgrade also features a QR code on the wheel for quick access to important safety information and a patent-pending Optimum Use Line to help get the most out of the wheel. Using the wheel to its full life reduces changeovers, which helps users be more productive while reducing waste and abrasive spend. An advanced 2.0 bond formulation on the grinding wheels reduces uneven edge wear and chipping, also improving operator experience and extending wheel life.

See also: Weiler Corporation

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Welding and Joining

Welding and Joining3M's "Clash of the Grinders" Returns: New season of Welding ...

November 6, 2024

Finishing

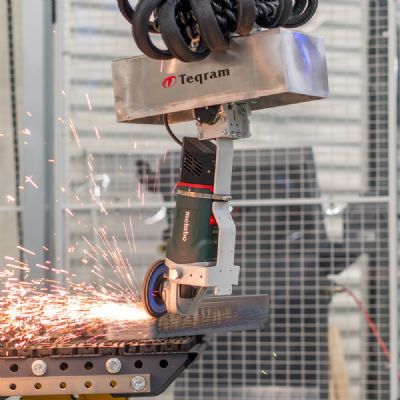

FinishingVia 3D Vision, Robotic Grinding Without Programming

Monday, March 3, 2025