Abrasive-Nylon Wheel Brushes Deburr Hard Metal Parts

May 15, 2020Comments

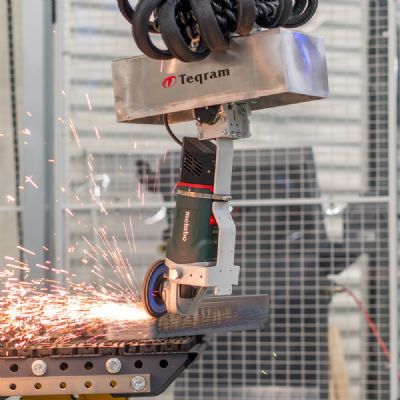

A wheel brush often is the ideal solution for applications

calling for surface finishing, cleaning, polishing, deburring, edge blending or

removal of paint, rust or other contamination. A type of power brush, motor-driven

wheel brushes, circular in shape with uniform distribution of the fill

materials extending radially from the center core to the periphery, may feature

an arbor hole or keyway that supports their use with grinding equipment or CNC

machinery.

A wheel brush often is the ideal solution for applications

calling for surface finishing, cleaning, polishing, deburring, edge blending or

removal of paint, rust or other contamination. A type of power brush, motor-driven

wheel brushes, circular in shape with uniform distribution of the fill

materials extending radially from the center core to the periphery, may feature

an arbor hole or keyway that supports their use with grinding equipment or CNC

machinery.

When employing metal-wire filaments, wheel brushes prove ideal for light deburring, edge blending and general surface finishing. The brushing action occurs at the edge or face of the tool.

However, when used on harder materials, wire filaments can break off, or deform―even if crimped. Although knotted-wire options are available for more aggressive deburring, for today’s hardened steels and alloys, even this type of wheel brush is not sufficient.

Instead, for the most aggressive deburring or surface finishing, a wheel brush using abrasive-nylon filaments made of silicon carbide offer a solution. Taking it one step further, diamond grit can be used for the hardest metals and alloys in use today.

For JR Precision & Welding, a Houston, TX, machine shop specializing in welding, 3D printing and three- and five-axis CNC manufacturing, removing large burrs from holes in a hard 4140 steel-alloy part proved challenging.

The part in question, a muzzle brake, or compensator, connects to the barrel of a rifle or pistol to help control recoil and the rising of the barrel that normally occurs after firing. Muzzle brakes utilize slots, vents, holes, baffles and similar devices to redirect a portion of propellant gases to counter recoil and unwanted muzzle rise. Where and how these holes are placed in the muzzle brake has a tremendous effect on the influence of the brake in terms of recoil and muzzle movement.

When machining these holes at JR Precision & Welding, large burrs formed at the oval-shaped gas ports. The Type 410 muzzle-brake cylinder, hardened and tempered to a tensile strength of 850-1000 Mpa, was machined in an elliptical path, which increased the size of the burrs created.

“The burrs that were created were razor sharp and thicker than we wanted them to be on each of the four main ports in the part,” says James Mawazeb, director of operations and lead engineer at JR Precision & Welding.

The abrasive-filled nylon filaments are set into molded

cores, allowing higher filament densities and putting more cutting tips at the

point of attack, according to company officials, who note that the durable,

self-sharpening filaments provide excellent wear life.

The abrasive-filled nylon filaments are set into molded

cores, allowing higher filament densities and putting more cutting tips at the

point of attack, according to company officials, who note that the durable,

self-sharpening filaments provide excellent wear life.