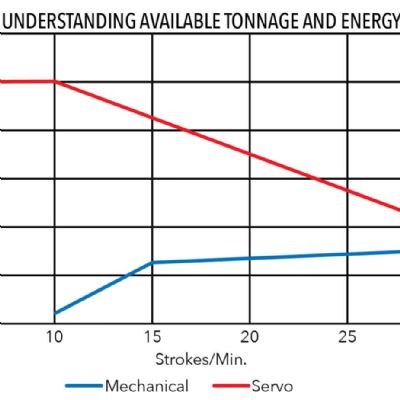

Traditionally, mechanical and hydraulic presses each have offered specific benefits, with mechanicals providing higher stroke speed, simpler set up and maintenance, and high repeatability. Hydraulic presses deliver full energy throughout the press stroke along with freely programmable slide motion and energy control. Introducing servo motors into the hydraulic-press equation retains the stated advantages, with plenty more added.

Reduces Complexity of Hydraulics

Incorporating servo motors in hydraulic-press setups has allowed machine builders to eliminate hydraulics previously needed to control ram-cylinder force and direction. That’s important, as while standard hydraulic presses have improved greatly over the years in terms of leakage and wear of pumps, valves, hoses and fittings, stampers still, at a time and money cost, must perform monitoring and maintenance of hydraulic components. And, a lesser hydraulic footprint translates to less oil usage, meaning less need for cooling components for hot oil. With these burdens eased, servohydraulic presses can offer savings to 30 percent in maintenance time and costs as compared to traditional hydraulic presses, according to some press builders, along with longer service life.

Incorporating servo motors in hydraulic-press setups has allowed machine builders to eliminate hydraulics previously needed to control ram-cylinder force and direction. That’s important, as while standard hydraulic presses have improved greatly over the years in terms of leakage and wear of pumps, valves, hoses and fittings, stampers still, at a time and money cost, must perform monitoring and maintenance of hydraulic components. And, a lesser hydraulic footprint translates to less oil usage, meaning less need for cooling components for hot oil. With these burdens eased, servohydraulic presses can offer savings to 30 percent in maintenance time and costs as compared to traditional hydraulic presses, according to some press builders, along with longer service life.

Though servohydraulic technology does reduce the need for some hydraulic components, those components remaining have been optimized. For example, Macrodyne employs pressure-compensated axial piston pumps with electronic pump control, extreme high-pressure piston pumps and servo-controlled valves, according to company officials, which help deliver precision servo-controlled programmable motion and power when needed.

For its part, Sutherland Presses touts a combination of active fluid management and advanced servo motors that adjusts fluid volume and motor speed to match the required workload, enabling dynamic adjustment of tonnage from 10 to 100 percent at any point in the stroke cycle.

And, Greenerd’s new closed-loop servo-hydraulic system dramatically improves stroke depth control, it says, guaranteeing consistent, repeatable results. In many applications, this system eliminates the need for “kiss” blocks.

Put it all together and servohydraulic presses can achieve pressure repeat accuracy of ±1 percent.

Big Energy Savings

Precision control of force and acceleration enabled by servo-driven technology translates to significant energy savings—as much as 80 percent depending on the application as compared to conventional hydraulic presses—without sacrificing power. For example, AP&T boasts servohydraulic technology that delivers acceleration and deceleration force to 250-percent higher than that of a conventional hydraulic press, thus enabling increased production capacity.

Energy savings occur in many ways beyond precision ram control, as an overview from AP&T on its technology makes clear. Heat loss generated by pressure valves can be avoided, for example, and some servo motors can serve as generators. And, braking energy distributes to motors used for acceleration and forming via a kinetic storage system and central direct-current converter. With energy stored internally, peak loads don’t necessarily require electricity usage from the grid, and stored energy surpluses can be restored to the grid.

Sustainable Solution

Significant energy and oil savings outlined above point to servohydraulic presses as environmentally sound technology that creates a more hospitable work atmosphere. To that end, hearing is believing—servohydraulic presses run more quietly than traditional hydraulic presses. Given all of this, plus the fact that these presses require less hydraulic components and fewer replacement parts throughout a longer service life, servohydraulic technology represents a sustainable path forward in metal stamping.

Applications Abound

Similarly to servomechanical presses, automotive is the big application driver that brought servohydraulic presses to North American shores. The need for high forces to shape aluminum in automotive stamping, for example, cried out for a servohydraulic solution, but press builders had to contend with challenges related to high-speed production and the resulting energy usage. They have met those challenges with today’s technology, and automakers and tier suppliers increasingly rely on servohydraulic presses for this type of work.

The technology also proves beneficial in hot stamping applications where high forces must be held longer on ever-stronger materials. Dialed-in stroke parameters enable more intricate and precise work on these materials without overly stressing already stressed tooling. Other applications include motor-bearing press fitting, electrical-connector press fitting, press hardening and composite-material forming.

Find these presses in transfer applications as well, and, of course, in deep drawing, where traditional hydraulic presses have shined for years. Consider servohydraulic presses, uniting the consistently high force delivered by hydraulic presses with the stroke-control capabilities of servomechanical presses, when you need programmable power. MF

View Glossary of Metalforming Terms

See also: Greenerd Press & Machine Co., AP&T North America Inc., Sutherland Presses Inc., Macrodyne Technologies, Inc.

Technologies: Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Stamping Presses

Stamping PressesHydraulic Press Innovations Move into Mainstream

Jeffrey Walsh Thursday, March 27, 2025

Finishing

FinishingAP&T Launches Skylines Press-Hardening System for Large, Com...

Monday, March 24, 2025

Without diving into the weeds, servo motors have the same basic parts as a regular motor: stator and rotor. The addition of servo technology, with the servo device as an actuator—linear or rotary—provides positioning via a signal. In simple terms, the motor responds quickly to the servo signal, enabling rapid acceleration. A servo motor, combining position signaling and rotational power, enables precise control of position velocity and acceleration.

Without diving into the weeds, servo motors have the same basic parts as a regular motor: stator and rotor. The addition of servo technology, with the servo device as an actuator—linear or rotary—provides positioning via a signal. In simple terms, the motor responds quickly to the servo signal, enabling rapid acceleration. A servo motor, combining position signaling and rotational power, enables precise control of position velocity and acceleration.  In a servohydraulic stamping press, servo motors tied to ram movement and valve operation—and, in some cases, for ram control in press cushions—allow for precisely dialed-in settings for each application, considering the overall job as well as tooling and material. Using press controls, stampers can program stroke movement and force anywhere in the stroke to provide precise forming action—and dwell time as needed. This capability makes servo-driven presses extremely flexible, and quite energy-efficient due to the tailored power.

In a servohydraulic stamping press, servo motors tied to ram movement and valve operation—and, in some cases, for ram control in press cushions—allow for precisely dialed-in settings for each application, considering the overall job as well as tooling and material. Using press controls, stampers can program stroke movement and force anywhere in the stroke to provide precise forming action—and dwell time as needed. This capability makes servo-driven presses extremely flexible, and quite energy-efficient due to the tailored power.

Video

Video