Waterjet Cutting—The Swiss Army Knife of Metal Fab

July 1, 2011Comments

This manufacturer envisions a world made of fabricated sheet and plate, using waterjet cutting and other processes to build products typically made from machined castings.

“We manufacture inhouse as much as possible,” says operations supervisor JC Schatz (whose father John is the company’s president), “due to the low-volume high-mix nature of our work. Also, downtime is critical to our customers. Any delay in obtaining replacement railroad parts costs the transit authorities dearly. Inhouse control of the manufacturing operations allows us to turn on a dime and truly serve the customers.”

Twinco’s vast range of capabilities has both Schatzes pledging to grow the company’s contract-manufacturing business (aside from its work for transit authorities) from five percent currently to 15 percent within the next two years.

Making the World from Fabricated Sheet and Plate

Twinco’s roots trace back more than 45 years, as a tool and die shop providing electromechanical components for equipment OEMs serving the railroad industry. In the 1980s it began to work more and more directly for the transit authorities (New York City, Chicago and others).

“The key to our success, says John Schatz (whose father founded Twinco in 1963), “is being able to offer a wide variety of inhouse processing capabilities, so we can select the best process for each specific job, particularly the low-volume (one to two) high-mix jobs. Doing all of the work inhouse allows us to inspect in-process, not after the fact. We don’t inspect quality into our parts; we manufacture quality into our parts.”

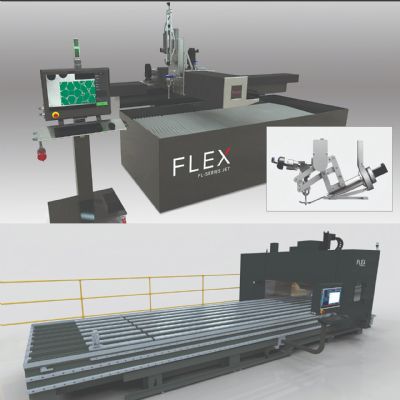

Twinco’s latest vertical step to diversification: the addition of waterjet cutting. In 2005 the firm added a 60,000-PSI machine, coinciding with its move to its current location from a much smaller 22,000-sq.-ft. shop.

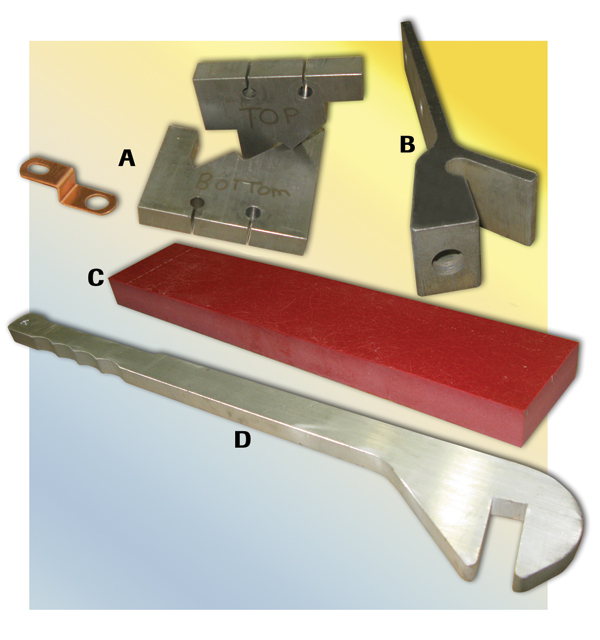

“Waterjet cutting really is like the Swiss Army knife of metal fabrication,” says JC, “allowing us to cut all sorts of materials—metal alloys, plastics, rubber, glass, etc. Much of what we traditionally manufacture—train-stop housings and similar products—have been made of machined castings, but we see opportunities to more cost effectively manufacture these products by fabricating sheet and plate, and waterjet cutting helps facilitate that. Along the same line, we’ve recently added a press brake and, later this year, plan to invest in a robotic-welding cell to bolster our fabricating capabilities.”