Bringing Waterjet Cutting Inhouse—a Lucrative Decision

April 1, 2012Comments

A wind-turbine manufacturer makes waterjet cutting a core competency. Bringing the process inhouse has added 20 percent to the firms top line, allowing it to pay for its cutting machine in less than 2 yr.

When wind-turbine manufacturer Kronos Energy Solutions, Cordova, TN, sought to improve its own level of green-fabricating processes, it turned to waterjet cutting to take on a portion of its production, custom and prototyping work. Kronos designs and manufactures small vertical-axis turbines. Company president and CEO John Bogensberger launched Kronos in 2009; prior to that, he worked for a high-production manufacturing company fabricating primarily sheetmetal. “I first saw waterjet-cutting machines at an IMTS show in 1998,” Bogensberger says. “I was intrigued with the process because it produced no toxic gases, dust nor dangerous chemicals. But I felt I couldn’t justify the machines in a high-production environment cutting sheetmetal.”

Bogensberger took a fresh look at waterjet cutting—and began to think seriously about bringing the work inhouse—after attending the FABTECH 2010 show in Atlanta. There he was introduced to a new waterjet-cutting machine, the Mach 4 model from Flow, outfitted with the company’s Dynamic Waterjet XD technology. “We’ve als known that the waterjet-cutting process is extremely flexible, but when I experienced the speed and accuracy possible with the Mach 4, we knew we had to have one.”

Victory Over Stream Lag and Taper

Two types of part-quality issues typically plague abrasive waterjet cutting: stream lag and taper. Both of these accuracy hurdles can be cleared by significantly reducing cutting speed, but cycle time and cost per part rise with equal significance.

|

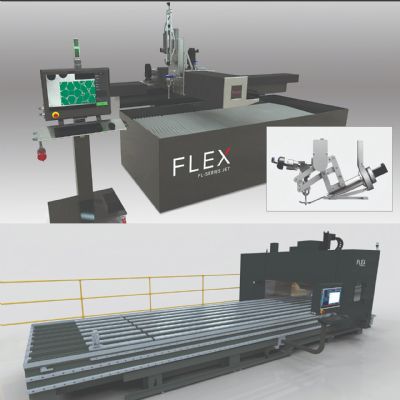

| Since Kronos installed this Mach 4 FlowJet waterjet-cutting system—outfitted with a 13- by 6.5-ft. table—costs compared to outsourcing work have reduced dramatically, allowing the company to pass savings directly onto its customers. |

Stream lag—evidenced by the exit point of the waterjet lagging behind the entrance point—causes geometry errors as it sweeps out cone shapes instead of circles, and causes corner wash-out on inside corners. And, V-shaped taper naturally occurs as the power of the waterjet dissipates during cutting. The faster the cutting speed the greater the kerf-taper error, which can be as much as 0.01 in. per side. As with stream lag, slowing cutting speed will minimize taper, but will restrict productivity and increase garnet consumption per inch of cut.

Flow’s Dynamic Waterjet with Active Tolerance Control avoids taper and stream lag during flat-stock cutting, says the company, maximizing cutting speed. The technology combines control software with precision machine-tool design and an articulated end-of-arm wrist.