New Laser = New Opportunities; Fiber Next?

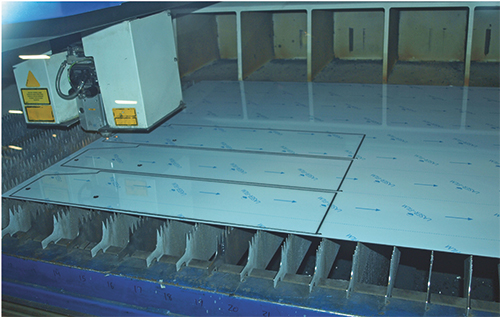

“With the addition of the new 6-kW machine,” continues Fuller, “we’ll likely replace the L2510 in a few years with a fiber-laser cutting machine, to handle work 3⁄16 in. and thinner. We just have to build more volume in that area.” Fuller’s new machine adds plenty of sheet- and plate-cutting capacity to the shop, since, as he notes, it can carve up 3⁄8-in. stainless-steel exhaust flanges at 60 in./min., compared to 20 in./min. on the 2530.

His initial customer for the tube-cutting capability of the RotoLas-equipped TruLaser 3030 is an OEM machine builder serving the plastic-processing industry. “We’re fabricating machine frames from 4- by 4-in. square tube,” Fuller explains. “With the RotoLas option, we can automatically set tube lengths—no more measuring —and cut tabs and slots in the tubes to ease fitup and welding. Positive locating dramatically quickens assembly time and improves accuracy and repeatability, keeping us one step ahead of the competition.”

Noting that he opted for nearly every “bell and whistle” available on the 3030, Fuller describes the benefits of one particular new machine feature: Trumpf’s CoolLine water-mist applicator. Located in a specially designed cutting head, the CoolLine nozzle directs a water mist around the laser beam as it reaches the workpiece. The water mist reduces heat transfer to the cutting zone, enabling tighter corner radii and the cutting of smaller hole diameters than would otherwise be possible. Also, according to Trumpf literature, keeping the cut zone cooler allows fabricators to tighten up their nests in thick material. Optimizing material utilization and reducing scrap.

“Customers want smaller diameter holes in the heavy-gauge flanges,” says Fuller, “a ½-in. hole in ¾-in. plate for example. Now we can do it, using the CoolLine nozzle. Before, we had to drill those holes—not how I want to do things.”

Vaporizing PVC

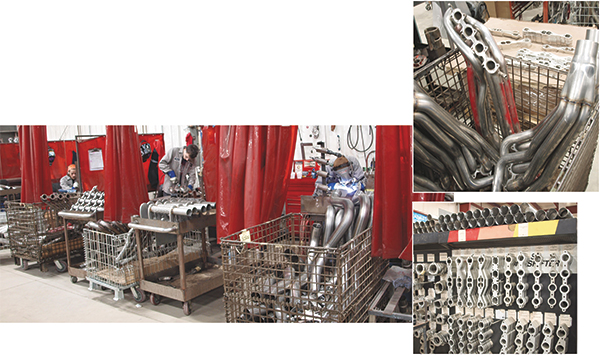

We spied the 2510 cutting PVC-coated stock, a common occurrence at Stainless Works. Fuller’s operator has perfected the art of vaporizing the coating around the cut line—a 1⁄16-in.-wide path or so—to optimize cut-edge quality.

“He powers down the beam a bit and raises the standoff distance,” explains Fuller, “to remove the coating prior to cutting. While this increases production time by about 20 percent, it eliminates any fuzz on the back of the cut edge that we might otherwise see, as a result of the PVC driving down through the cut.

“The parts look flawless—we do this on all of the bank-vault door skins, and on other parts,” Fuller continues. “And, the extra processing step also causes the PVC to adhere better to the edge of the part so it won’t peel a during downstream press-brake bending operations.”

Getting Engineers Out of the Office and Into the Shop

Fuller’s added two Trumpf CNC press brakes to the shop in recent years, to become a full-service contract manufacturer. He’s also equipped four manual arc-welding booths with the latest Lincoln gas-tungsten-arc-welding equipment, and purchased a self-contained Panasonic robotic gas-metal-arc-welding cell. Additional processes offered include assembly, finishing and machining. Customers come from numerous industries including automotive, computer, electrical, heavy equipment and restaurant equipment.

On staff are two engineers that allow Stainless Works to offer engineering support to customers. And, Fuller proudly exclaims that his engineers are not allowed to take the all-too-common attitude that ‘if we can draw it they can make it.’

“Instead, I require our engineers to come down to the shop and run the machines,” Fuller says, “if for no other reason but to make them fully aware of what it takes to actually make the parts they design. They then can apply that knowledge during the design process, improving part designs for our customers and often allowing us to run faster with less complexity, so we can provide higher-quality parts at an overall lower price.”

Growth Begets Software Upgrade

Such dramatic growth, encompassing more than 2000 exhaust products and hundreds more products on the custom-fab side, has led Fuller to upgrade his shop-management software. The goal: increased visibility into the shop floor, more accurate inventory control and purchasing and streamlined production. Paperless flow also is on the wish list.

In fact, in October 2013 JobBoss released its BOM Import module, software designed to minimize the time required to convert bill-of-materials data into production requirements. A press release, quoting JobBoss senior product manager Sue Irby, notes that “BOM Import captures data from a single or multi-level BOM structure and imports it into JobBoss to create quotes and jobs.” Automating the import process is exactly want Fuller is looking for, to avoid manually entering BOM data and to reduce or eliminate inaccurate material inventory on the shop floor. Irby adds:

“Shops can expect a time savings of as much as 2 hr./day per engineer (using BOM Import), for a quick return on investment.”

What’s next on Fuller’s investment agenda?

“I’m looking for automated sawing equipment,” he shares. “I want to be able to stack up a bundle of tubes on a loader, program cut lengths and the number of cuts and walk a. I haven’t found the right machine yet, but I’ll know it when I see it.” MFView Glossary of Metalforming Terms

See also: TRUMPF Inc.

Technologies: Cutting