Learning the Laser

Since the Platino was Carmeco’s first laser, there was a small yet definite learning curve when the machine first arrived. “When the machine was first installed, it wasn’t very busy,” reflects Carr. “But all of that changed once we became comfortable with the technology.”

Carmeco has 48 employees that work 10-hr. shifts, four days/week. Initially, the Platino ran four 10-hr. shifts per day, but now runs lights out, clocking 18-hr. workdays.

“The Platino and accompanying 10-shelf TowerServer have greatly increased our flexibility,” says Carr. “Previously, we might have been one or two weeks out before we could get a rush job into the production schedule. Now if we have to jump in and laser cut something for a rush job, with the tower we can switch from cutting 12-gauge material, for example, to ¼ in. in just a few minutes. We can get the job in and out quickly and then jump right back to the job we had been running.”

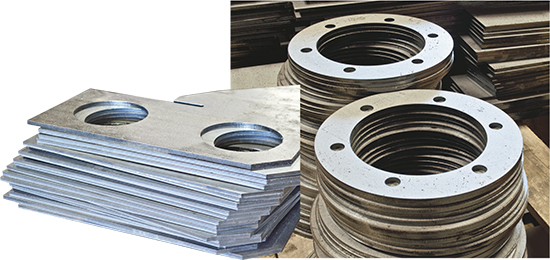

Carmeco’s new laser-cutting machine has opened the door to new business, and delivered several new customers to the firm. “We now can process smaller runs with ease,” notes Carr. “In fact, we’ve taken some shorter-run jobs off of our stamping presses and put them on to the Platino. It also has opened up new opportunities with existing customers, and helped improve our ability to get involved in the design stage by building prototypes for our customers.”

Quality Delivers Cost Savings

Carr also notes quantifiable returns on the cutting-machine investment resulting from the cut-edge quality the laser provides.

“Before purchasing the Platino, we had been, for example, fabricating a large 14-gauge part which we had to ship to an outside vendor for plasma cutting,” explains Carr. “Then we had to grind the cut edges to enable repeatable, high-quality welding (the firm performs robotic welding on parts to 48 by 60 in.). Now, laser cutting the part inhouse allows us to skip the edge-grinding process, which has reduced our time to fabricate the product by one hour.”

The Platino also has replaced most of the shearing that used to occur at Carmeco.

“Our shear has cobwebs all over it now,” jokes Carr. “Using the laser is so much easier and faster. Some of the shearing work was on ¼-in. material, and our employees would have to drag 60 by 120 sheets around, which weigh 400 lb. They’re more than happy that the Platino has eliminated that physical labor—the tower does that work now, and it doesn’t even sweat or grunt.” MF

Article provided by Prima Power, Arlington Heights, IL: 847/952 6500, www.primapower.com.View Glossary of Metalforming Terms

See also: Prima Power North America, Inc.

Technologies: Cutting, Pressroom Automation