Blank Stacker Headed to Aluminum Toll Processor

November 1, 2009Comments In December 2008, Aluminum Blanking Co., Pontiac, MI, became the proud new owner of an aluminum blank-stacking system designed to protect the surface-sensitive materials that it processes—aluminum and stainless-steel alloys blanked on seven lines with cut-to-length capabilities.

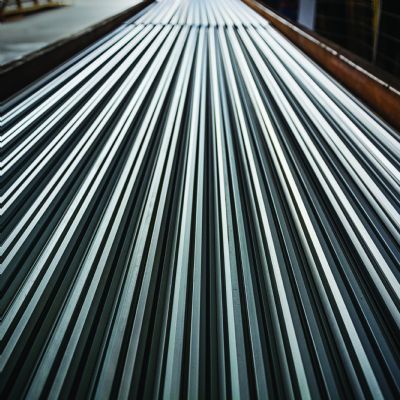

The new stacker, from Atlas Technologies, Inc., Fenton, MI, processes coil into stacks of blanks in sizes to 500 by 110 in. with stack weight to 30,000 lb. It can process blanks into two stacking stations with lift tables that can operate independently. A weight-verification system allows for material accountability—once weighed, a blank stack proceeds to a dual wrapping station. The station boasts a lift and transfer unit for palletizing each wrapped stack, which then proceed to a second wrapping station where pallet and stack are wrapped together, ensuring safe transit.

Atlas Technologies: 810/629-6663; www.atlastechnologies.com

View Glossary of Metalforming Terms

See also: Atlas Technologies, Div. of Stonebridge Technical Enterprise

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingBlanking Line Supports Automotive’s Southeastern-U.S. Progre...

Brad Kuvin Wednesday, February 8, 2023

Coil and Sheet Handling

Coil and Sheet HandlingAutomatic Feed Introduces Edge Stacker for Surface- and Edge...

Thursday, February 17, 2022

Coil and Sheet Handling

Coil and Sheet HandlingAutomatic Feed Debuts New Coil-Feed Lines, and the Edge Stac...

Monday, February 7, 2022