Jim Ward

Jim WardThe Basics of Coil Processing, Part 1: Unwinding the Coil

January 1, 2012Comments

This is the first article in a series that MetalForming and Coe Press Equipment will present in 2012 on the basics of coil processing.

Modern coil-handling and feeding equipment has dramatically increased the efficiency and throughput of pressrooms around the world, as well as helped to eliminate the dangers and repetitiveness of hand feeding. Metalformers can select from among a variety of coil-feeding methods and types of equipment to accommodate their unique needs. When doing so, they must consider several parameters to ensure selecting a system that best meets the requirements of the application, including price, operating cost, coil weight, material type and thickness, feed length and speed requirements, material finish, floor-space availability and controls compatibility.

In this series of articles, we will discuss such basic operations as unwinding and straightening the coil, and feeding the press. Along the we will discuss the various types of equipment used for each process, helping to provide basic guidelines for investing in new coil-processing lines.

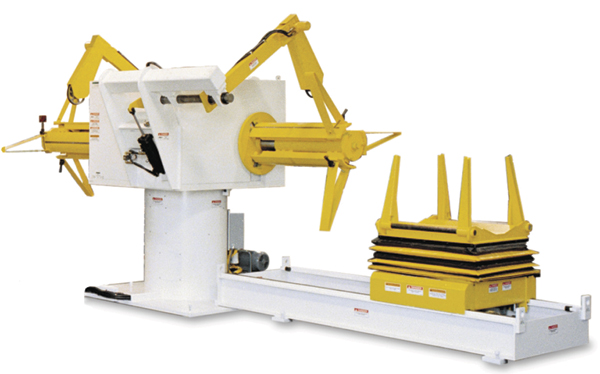

Fig. 1—A combination cradle/straightener unwinds the coil off of the top to a powered straightener and into a horizontal loop. Of the three coil-cradle configurations, this style requires the greatest amount of floor space due to the horizontal loop.

The focus of this article: The various approaches to coil unwinding— coil cradles (or coil boxes), centering reels and pallet decoilers. Look for part two later this year, where we will explore straightening options for coil lines.

Coil Cradles

Coil cradles hold a coil by the outside diameter, cradling it on powered rollers called nest rolls. This approach primarily finds use in medium- to heavy-gauge applications when material marking is not an issue. The cradle contains the coil within a box or framework that provides protection for the operator, by preventing the coil from telescoping. The outer wrap is contained between the weight of the coil and the nest roll as it unwinds, helping to prevent clockspring as well as controlling the coil for threading, particularly useful when feeding heavy-gauge or high-strength materials. However, this same feature also can cause problems with thin or cosmetically sensitive material, as it tends to mark or distort the sheetmetal.

A rule of thumb: Avoid use of coil cradles for processing material less than 0.06 in. thick.

Another disadvantage of the cradle-style unwinder is that it can operate inefficiently when rewinding and rebanding partially run coils. After running in a cradle for a period of time, the coil tends to clockspring internally and the wraps become loose, making it impossible to re-band into a nice, tight coil. Additionally, coil cannot be rebanded until it is lifted off and out of the nest rolls.

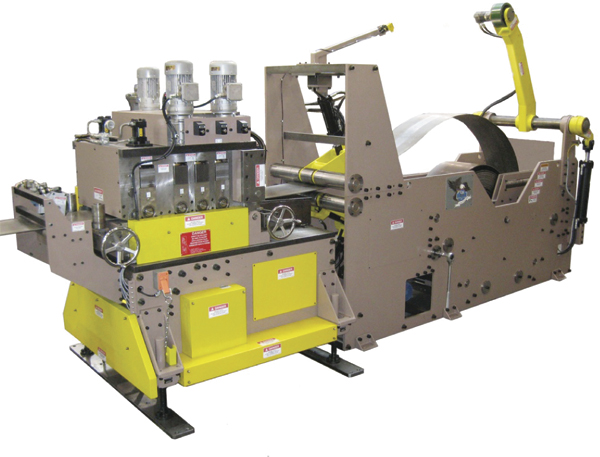

Fig. 2—The third type of cradle—a cradle-feeder straightener—unwinds, straightens and feeds directly into the press without the need for a slack loop, making it a very compact and self-contained coil-feeding system.

Manufacturers offer coil cradles in three basic configurations. A combination cradle/straightener (Fig. 1) unwinds the coil off of the top to a powered straightener and into a horizontal loop. Of the three configurations, this style requires the greatest amount of floor space due to the horizontal loop, but lends itself well to quick coil changes with the addition of a spare coil load ramp and an unobstructed rear loading area.

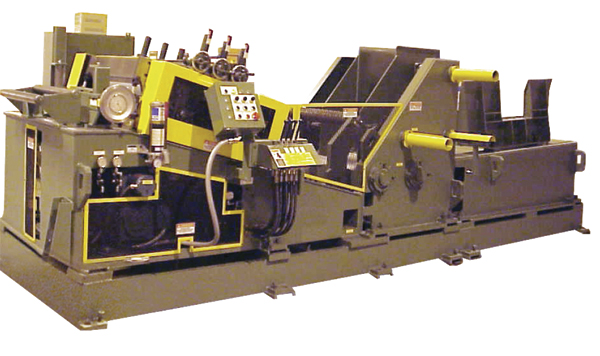

The inline style of coil cradle unwinds the coil from the bottom into a vertical or overhead loop. This space-saving design creates a loop area that does not consume as much floor space as the combination configuration, although it can require substantial vertical height. Inline coil cradles are available with only a pair of pinch rolls to assist in peeling the material off of the coil, or they can incorporate a powered straightener. Basic models for small coils pay off directly from the nest rollers without the aid of pinch rolls or a straightener.