Crossover 3D Printer

August 7, 2012Comments

Stratasys, Minneapolis, MN, introduces the Fortus 250mc production 3D printer--a rapid-prototyping and production machine designed to give users the convenience of a Dimension 3D Printer with the flexibility of a Fortus Production 3D Printer.

Stratasys, Minneapolis, MN, introduces the Fortus 250mc production 3D printer--a rapid-prototyping and production machine designed to give users the convenience of a Dimension 3D Printer with the flexibility of a Fortus Production 3D Printer.

The company’s first crossover system, the Fortus 250mc combines the ease of use and affordability of Stratasys’ Dimension 3D printers with the control of Insight Software, used to drive the Fortus line of production 3D printers. With Insight, users gain added control of build speed, part accuracy and feature detail.

Like all Stratasys additive-manufacturing systems, the Fortus 250mc is based on the fused deposition modeling (FDM) process. “Engineers interested in this new product will likely be traditional 3D printer candidates who want more sophisticated build-parameter control,” says product manager Mary Stanley. “Users are moving beyond prototyping into production with their additive-manufacturing machines. The most common manufacturing application is to build functioning manufacturing tools like jigs and fixtures to be used in the production process.”

The Fortus 250mc has a 10 x 10 x 12-in. build envelope and offers three build layer options: 0.007, 0.010 and 0.013 in. To create parts, the machine uses ABSplus thermoplastic, which offers excellent mechanical proprieties including impact strength, tensile strength, flexural strength and bonding strength for tough, functional applications. ABSplus comes in ivory, white, blue, fluorescent yellow, black, red, nectarine, olive green and gray.

Stratasys, Inc.: 888/480-3548; www.stratasys.com

Technologies: Bending

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingCreative Approaches to Common Press Brake Challenges, Part 1...

Justin Talianek Tuesday, April 30, 2024

Bending

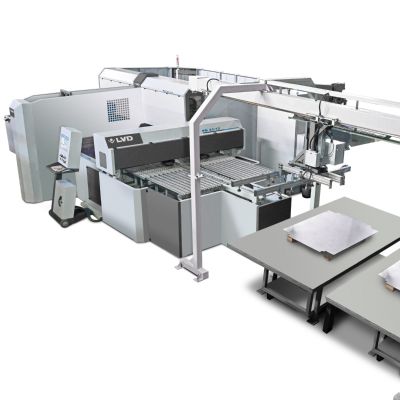

BendingLVD Adds Panel Benders to Product Line

Tuesday, January 2, 2024

Bending

BendingFully Electric Plate-Rolling Machines Also Process Sheet Met...

Tuesday, October 31, 2023