Digitizing the Press-Brake Bending Process

May 1, 2011Comments

As more and more fabricators enter the arena of low-volume high-mix production, they should look to take advantage of offline press-brake programming to enjoy huge benefits in time, efficiency and costs.

For many years, the blanking and laser-cutting stages of the sheetmetal-fabrication process have advanced to realize the advantages of offline programming. However, many shops have been slower to adopt this practice for the more-complex 3D bending process.

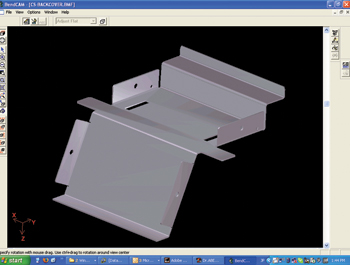

As computing power has increased to handle the 3D models required to process folded shapes, fabricators now can experience the advantages of virtually processing their formed parts. Fabricators working in a low-volume high-mix production environment can take advantage of offline processing and enjoy huge benefits in time, efficiency and costs.

Opening the Box

|

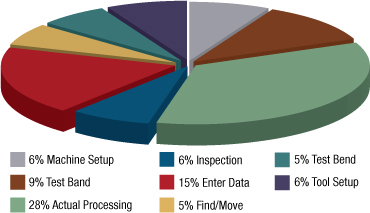

| Fig. 1—Nonproductive activities account for 72 percent of the typical press-brake operator’s time, while green-light time making parts comprises only 28 percent of an operator’s day. |

Prior to the blanking process, part data is imported into computer-aided manufacturing (CAM) software, used by a programmer for part processing on a specific machine. The program contains information on the tools required, as well as lines of code that the machine tool’s computer numerical controller (CNC) uses to process the part. This program downloads directly to the machine (laser-cutting machine or turret punch press, for example) with tool-setup information. The machine operator needs to do little more than call up the required program, install tools according to the information downloaded with the program, load material, make some minor adjustments to the machine and begin processing.

Since the program typically is saved, this becomes a highly repeatable operation, minimizing setup time since much of the work is done ahead of time while the machine processes other parts. An added benefit: The skill level of the machine operator need not be high, and operators are more easily trained for the job.

In many shops, press-brake bending remains a black box, with one or two talented individuals having the high skill level necessary to take material from a flat state to 3D formed parts. Many factors, such as tool selection, bend-sequence development, material properties and machine capabilities must be considered. All of this requires operators of high intellectual capability to generate a machine program that will produce parts within specifications. Often, this lengthy setup procedure occurs at the machine, at the expense of performing value-added work.

The greatest benefit of bending CAM programs: They externalize a significant percentage of the setup pie. Bend-sequence planning, tool selection and layout, and press-brake programming are removed from the floor, increasing green-light time.

A Focus on Green-Light Time

To get a better understanding of the benefits possible with digital processing, consider a typical nine-step bending process, from setup through production:

1) Find materials—Locate material and part information, such as drawings and process instructions.

2) Tool/bend sequence and selection—Specify the required tools for the job, and determine the sequence of bends.

3) Tool setup—Insert tooling into the machine.

4) Program creation—Enter bend data into the machine control.

5) Machine setup—Make all of the required manual adjustments to gauges, jigs, supports, etc.

6) Test bend—Make iterative setup adjustments to obtain the specified angle and flange dimensional tolerances.

7) Processing—Actual part production.

8) Inspection—Inspect parts before and during processing.

9) Data entry—Log the job and miscellaneous shop document requirements.

Studies performed in the bending area of many shops, including typical job shops and OEM facilities, have uncovered a poor ratio of value-added activities to nonvalue-added activities (Fig. 1). Nonproductive activities account for 72 percent of the typical press-brake operator’s time, while green-light time making parts comprises only 28 percent of an operator’s day. With the current trend of high-mix/low-volume processing, where many shops experience more job changes than ever before, green-light time can be even further reduced. New jobs usually require more lengthy setups, since the setup person must start from scratch when determining bend sequence and tool assignments. If this information is not recorded for future repeat runs of the job, this series of events repeats itself. Even if the setup person records the elements of the setup, most times it remains in his possession, unavailable for use by others.

With the pool of highly skilled brake operators getting shallow, shops will continue struggling to maintain a good level of accuracy and efficiency in their bending area. Additionally, differences in setup practices among setup personnel lead to inconsistencies in part specifications and quality. These inefficient practices all contribute to low green-light times, making press-brake bending a labor-intensive process and a bottleneck for many shops. Most fabricators address a bending bottleneck by adding more machines, shifts and operators, or upgrading to faster machines—none of which improve the ratio of value- to nonvalue-added time.

Video

Video