Specifically, the management team at the Columbus facility, primarily an assembly plant, sought to bring production of some of its critical yet relatively low-volume parts inhouse. So, Rosplock spent much of 2019 developing the business case to invest in nonmetal-AM equipment—for prototyping and production. With that success under his belt, he then set his sights on metal AM.

“We manufacture most of the company’s hydraulic pumps,” notes Rosplock, “and the related apparatus that goes into hydraulic systems. We are a high-value, low-volume producer, a perfect candidate for the cost targets of AM. We believe that metal AM, in addition to helping solve supply-chain issues, will play a significant role in allowing us to produce lighter-weight yet higher-performing pumping systems without sacrificing user safety, while allowing us to be more agile and bring new products to market quickly and efficiently.”

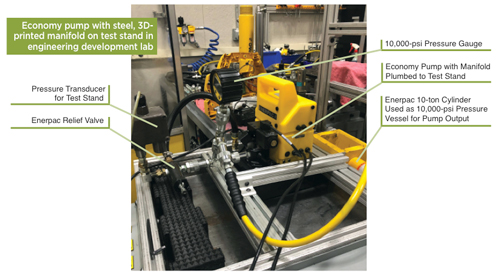

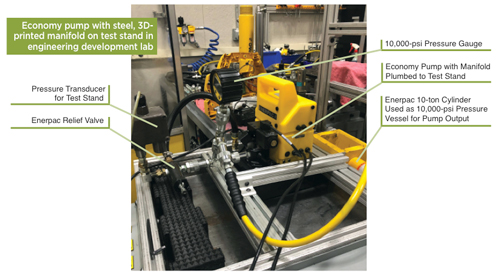

When we spoke with Rosplock, the firm was performing endurance tests on 3D-printed pump manifolds. “We are working with some of the machine builders, as well as a local contract manufacturer, Midwest Composite Technologies (MCT), to print test parts for us,” Rosplock says. MCT, in Hartland, WI, employs the direct metal laser-sintering (DMLS) process to produce metal-AM parts. In its print room: an EOS platform with a build volume of 9.85 by 9.85 by 8.5 in., and an SLM platform with a build volume of 11 by 11 by 13.8 in.

|

| To perform endurance tests on 3D-printed pump manifolds, Enerpac developed this test stand. |

“We’re testing parts printed from steel and aluminum,” Rosplock adds, “and potentially stainless steel as well.”

As the testing and validation process progresses at Enerpac, Rosplock expects to show management an aggressive return-on-investment-payback period for bringing metal-AM production inhouse, based on the principles of PPV.

“And, we expect to illustrate ways to leverage the unique capabilities of AM—internal cooling channels for example—to improve performance while also reducing production lead times,” he says. “With our nonmetal-AM investments, we’ve shown payback periods of 1 to 2 yr., based on PPV, and we expect we’ll show the same with metal.”

Rallying the Troops, and the Leaders

Advocating for technology investment has become a passion of Rosplock’s, as evidenced by his recent successes with AM at Enerpac, and he encourages other engineers throughout industry to develop similar skill sets. “As far as AM goes,” he says, “engineers already know what to look for in a part that should be considered for transitioning from traditional machining to AM. But once you get to that point, the next steps in developing the business case, to make a cost-justification argument to decision makers means learning how to communicate with other groups throughout the company, including accounting and marketing. You need to learn what they are looking for.”What are they looking for? “For starters, they expect you to understand the business climate and the needs of our customers,” Rosplock says. “They’ll want to know that the project is not just a good use of capital, but one of the best uses of capital for the current fiscal year. Illustrate your case with a real-world problem experienced by the production facility, and how the project will solve that problem while also improving customer satisfaction. Give yourself a relatively easy ‘first win.’”

Other key elements to building a business case, and to building momentum for a new-technology investment project, include forming a multifunctional project team right from the beginning, and allowing the team members to interject their thoughts and ideas, and also working to garner their support.

“I also suggest finding a project sponsor, other than yourself,” Rosplock continues, “and someone who is close to those on the decision-making team. Having someone higher up in the organization who either is a decision maker or works directly with them is crucial to setting the tone of your project’s review. Work with the sponsor to gain a clear understanding of the business climate, to help steer your business-case development in the right direction.”

Plant Manager as Advocate

Understanding the Accounting Term “Purchase Price Variance” (PPV) The “secret weapon” wielded by Michael Rosplock, manufacturing technology manager at the Enerpac manufacturing facility in Columbus, WI, in his efforts to make the business case for investments in new technology, including current AM projects, is a solid understanding of PPV. PPV represents the actual unit cost of a purchased (or manufactured) item minus its standard cost, multiplied by the quantity of actual units purchased. The standard price represents the price that engineers believe the company should pay for an item, given a certain quality level, purchasing quantity and speed of delivery, and should account for soft costs such as the impact of supply disruption. Calculating price variance based on bringing production inhouse versus outsourcing can help decision makers clearly evaluate a project’s return on investment. At Enerpac, “investments made in nonmetal printing technology yielded payback periods between 1 and 2 yr., based on PPV,” says Rosplock. “I’m confident we’ll be able to show similar results with metal AM.” |

For his part, helping Rosplock spearhead his AM projects was the facility’s plant manager, who has proved to be the perfect advocate and sponsor, Rosplock says. Naturally, the plant manager experiences first-hand the detrimental impact of supply-chain issues, and so he became the perfect sponsor for the AM-investment projects.

“We started, on the nonmetal project, with a handle used for our multi-position valves,” explains Rosplock. “When we began experiencing significant and disruptive supply issues, we decided to print the handles on a fused-filament fabrication (FFF) AM machine. That project turned into a nice first win for us, as we were initially able to print about 50 handles/week.

“To use that success to our advantage, as we built the business case to ramp up inhouse AM production,” Rosplock continues, “we socialized that initial win—also an important step. We made sure every person on the decision-making team had one of those printed handles on their desk. We made sure they understood the cost savings and production advantages of being able to produce these parts inhouse.” As a result of the project’s success, Rosplock has been able to add several new FFF machines to the plant floor.

Bigger, Better Things

Summarizing his approach to building the business case for AM at Enerpac, Rosplock stresses: “Make a good first impression, and make sure that you understand what project success looks like. Schedule regular, frequent report-outs to keep the decision makers informed on project status and make sure that they remain confident that they’ve invested wisely—in the project and in you.

“Now that we’ve moved on from nonmetal AM to metal, it’s rewarding to see the excitement building,” Rosplock concludes. “While the nonmetal printers we’ve invested in have delivered a lot of value to the company and have been sound investments and a great learning opportunity, we’re on to bigger and better things.” 3DMP

See also: Enerpac, EOS of North America, Inc., SLM Solutions NA, Inc.

Technologies:

Podcast

Podcast