Cobra Debuts Metal 3D-Printed Commercial Putter via HP, Parmatech Collaboration

February 24, 2021Comments

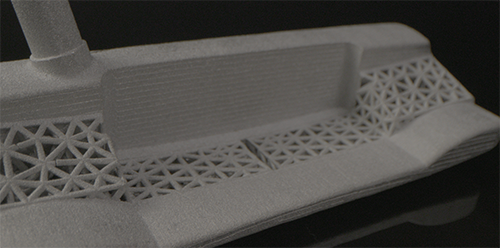

Cobra Golf has unveiled its King Supersport-35 putter, developed via a 2-yr. collaboration with Cobra engineers and teams at HP Inc. and Parmatech, and featuring a 3D-printed metal body with an intricate lattice structure designed to optimize weight distribution and deliver the highest-possible moment of inertia (MOI) in a blade shape, according to Cobra officials. Using Parmatech’s production capabilities and expertise, and HP’s Metal Jet 3D Printing system, the team’s developed a unique putter design that also employs SIK Golf’s Descending Loft Technology (DLT) in the putter head’s face insert.

|

| The new King Supersport-35 putter from Cobra Golf, developed via a 2-yr. collaboration with Cobra engineers and teams at HP and Parmatech, features a 3D-printed, latticed stainless-steel putter-head body as well as an aluminum-lattice insert. The collaboration employed Cobra’s inhouse engineering expertise as well as Parmatech’s production capabilities and HP’s Metal Jet 3D printing system. |

“HP’s 3D-printing technology allows us to utilize a complex lattice structure to remove weight from the center of the putter head and push significant amounts of weight to the perimeter,” says Jose Miraflor, vice president of marketing for Cobra Golf. “The result is superior MOI levels and massively increased stability and forgiveness. So not only is the 3D-printed production method more consistent, but it also allows us to design products in a new and superior way.”

Adding to the innovation, SIK Golf’s DLT has been engineered into the putter’s aluminum face insert―a design that saves weight from the front of the putter to give it a softer feel than a traditional all-steel SIK putter face.