What is Additive Manufacturing?

Additive Manufacturing is the process of adding metallic and/or nonmetallic material in order to create parts. The base material can exist in various forms, as a metal powder or a plastic filament, for example, with a form of heat used to adhere succeeding material layers, thus building the part. This differs from subtractive manufacturing processes such as machining, where material is removed to produce the part. Additive manufacturing enables production of unique structures, impossible to create via other manufacturing processes.

What is Part Inspection & Quality Control?

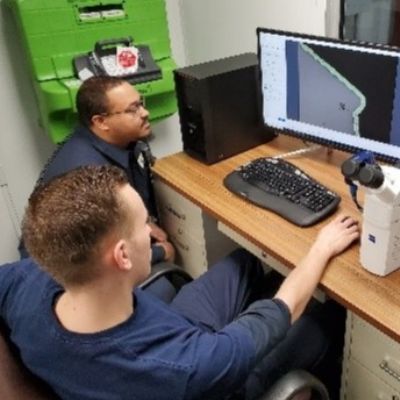

Part inspection/quality control for AM typically employs nondestructive surface inspection techniques that include fluorescent liquid penetrant, visual, surface roughness, and dimensional checks using gages, coordinate measurement machines, and white/red/blue light scanners. The typical internal inspections are radiography, electromagnetic, ultrasonic and (in rare cases) computed tomography (CT).

WEBINAR

WEBINAR