|

|

|

| Sponsored |

| More Power More Options for Metal Fabricators |

| The

power you need where it counts the most! The AXYZ Infinite Router comes

equipped with high-performance tools designed for high-load

applications, including spindles with horsepower ranges up to 15HP.

Optimize your flat sheet cutting and easily expand into aerospace,

automotive, and the marine industries. |

|

|

|

|

|

|

|

|

| Why Would You Recommend a Career in Manufacturing to Women? |

Dovetailing on MetalForming’s

2021 Women of Excellence in Metal Forming and Fabricating presentation,

Brad Kuvin, editorial director, underscores the importance of their

contributions, and the value in recognition.

“The goal of this program not only is to recognize excellence in our industry,” he writes, “but also to help support those women that may be interested in a similar career. We hope that these awards help inspire those who follow.” |

|

|

|

|

|

|

|

| Sponsored |

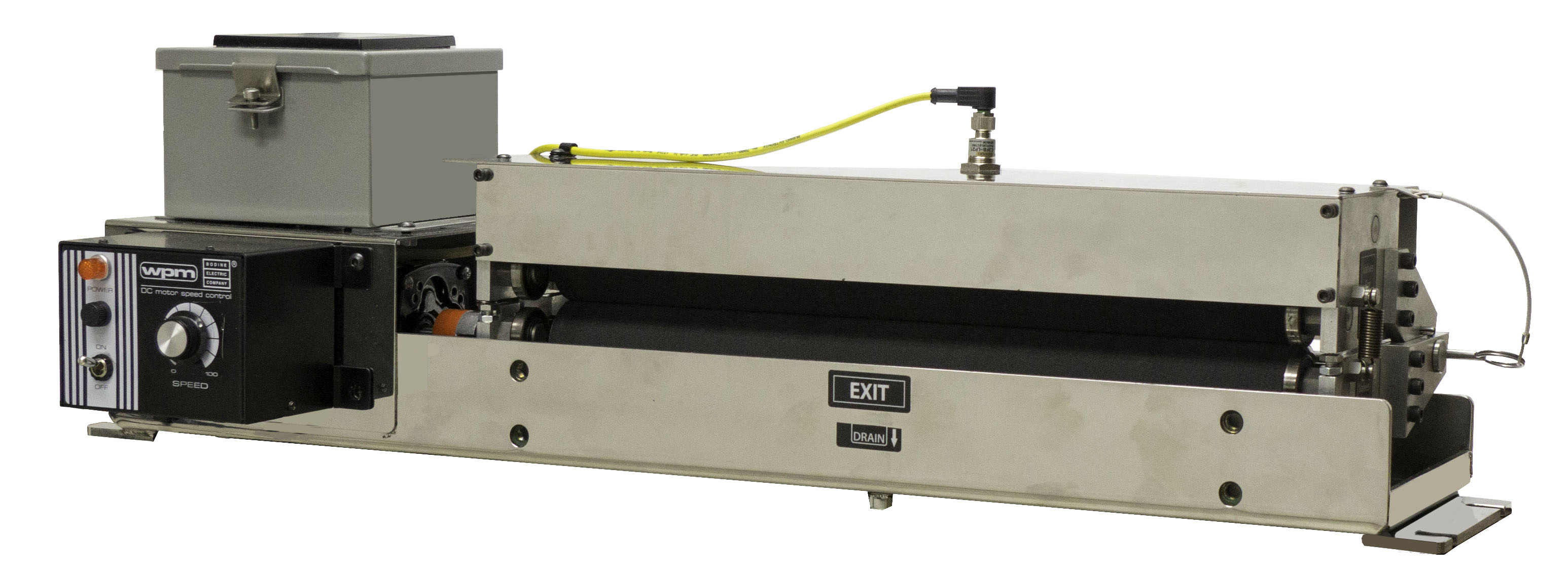

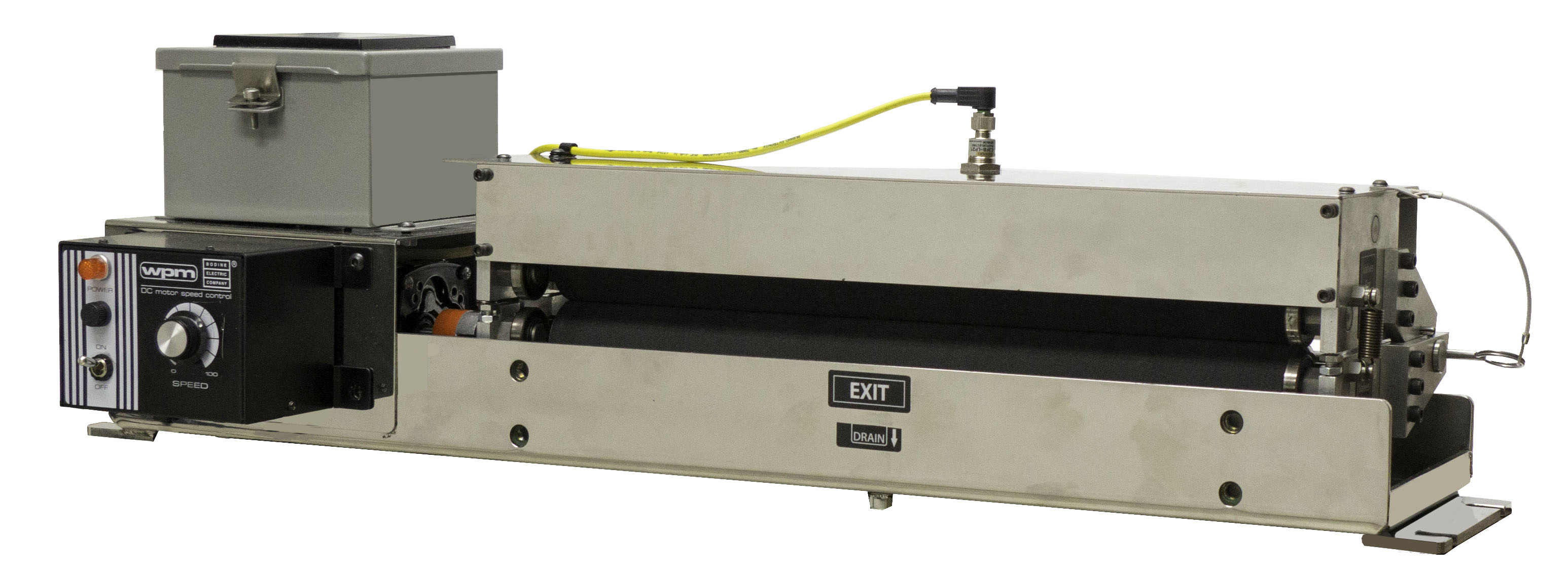

| A Lubricating System for Blanks |

| LSP

Industries manufactures the new B Coater, a lubricating system for

blanks for the stamping industry that can reduce lubricant consumption

by as much as 70% and increase productivity by as much as 30% over hand

lubricating. The Stainless Steel B Coaters are available in six sizes to

handle blanks from 6 inches or less up to 48 inches and are designed to

operate reliably in the rigorous metal stamping environment. B Coaters

are power driven with a variable speed motor to feed each blank through

the rolls while the lubricant is being applied to the blank. |

|

|

|

|

|

|

|

|

|

|

|

| FABTECH 2021 Shines in Chi-Town |

| MetalForming

recaps the exciting technology displayed on the show floor, designed to

boost productivity and quality for metal formers and fabricators. |

|

|

|

|

|

|

|

|

|

| Metal Stamping and Lubrication Technology Conference Coming Soon! |

| PMA and MetalForming magazine’s popular stamping conference is back and better than ever! In 2021, lubrication technology was added to the event, which took it to the next level. Now named the Metal Stamping and Lubrication Technology Conference, it is heading to Cincinnati, OH, for the first time on January 18-19, 2022. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Proven AHSS-Capable Straighteners |

| Lightweighting

strategies continue to push the growth of advanced materials. COE

straighteners are designed to effectively address both coil set and

crossbow issues. achieving the flatness required to process high

strength, high yield materials, all backed by FEA and software utilities

that prove out the performance capabilities |

|

|

|

|

|

|

|

|

|

|

| Forming Our Future In-Person Registration Sold Out; Virtual Options Available! |

| In-person

registration for Forming Our Future, February 13-16, in Key Largo, FL,

has officially sold out. But, you can still attend virtually! Individual

and group registration options are available, which provide access to

the conference app to view the presentations live or on-demand;

participate in the presentations by asking questions; and connect with

all in-person and virtual attendees, speakers and sponsors. If

interested in being added to the in-person wait list, submit this form. Note that the wait list does not guarantee in-person registration. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Tower MWF is Your Lubricant Solutions Provider |

| Tower connects metal stampers and tool shops with advanced metalworking fluid technology. With hazard-free products and 88 years of experience, you’ll get the best lubricant solution for your process. Let us help you solve a problem or simply make life easier. Start 2022 off right and contact Tower today! |

|

|

|

|

|

|

|

|

|

|

|

| From the December Issue of MetalForming |

| Don’t Blindly Use the 20-Percent Maximum Thinning “Rule” |

Some

metal forming companies choose to use a rule of thumb that calls for

a maximum 20-percent thickness reduction on a formed part compared with

the initial flat-blank thickness. In some cases, this substitution

proves acceptable, but in many cases using the 20-percent threshold only

confuses the proper course of action.

Welding Tool Steel: Challenges and Solutions

Welding can restore expensive tooling to production capability, but only

through the use of an appropriate plan of action and proper selection

of weld processes, filler materials and heat treatments. |

|

|

|

|

|

|

|

|

| Upcoming Issues |

January/February 2022

- Industry Outlook

- Servo Technology

- Laser Cutting

- Resistance Welding

- Technology and Enewsletter Focus: Software

February—Special All-Automotive Issue

- Automotive/EV Stamping and Fabricating, including stamping of AHSS

- Preview: Great Designs in Steel

- Technology and Enewsletter Focus: Presses

|

|

|

|

|

|

Pressroom Automation

Pressroom Automation

Event

Event